Coating stirring device for construction site

A construction site, stirring device technology, applied in mixers with rotating stirring devices, transportation and packaging, dissolving, etc., can solve the problems of poor stirring effect, achieve the effect of increasing mixing effect, novel design, and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

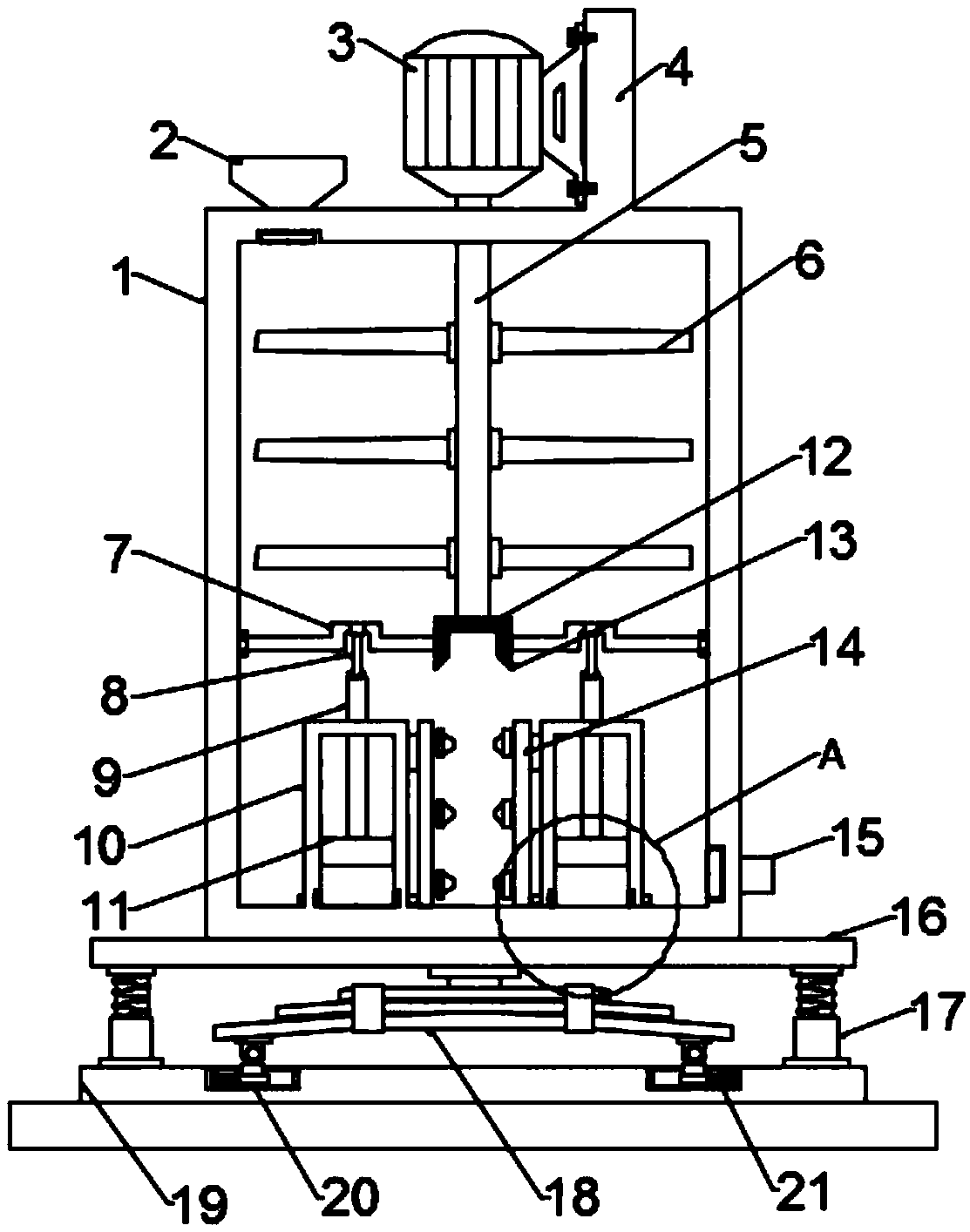

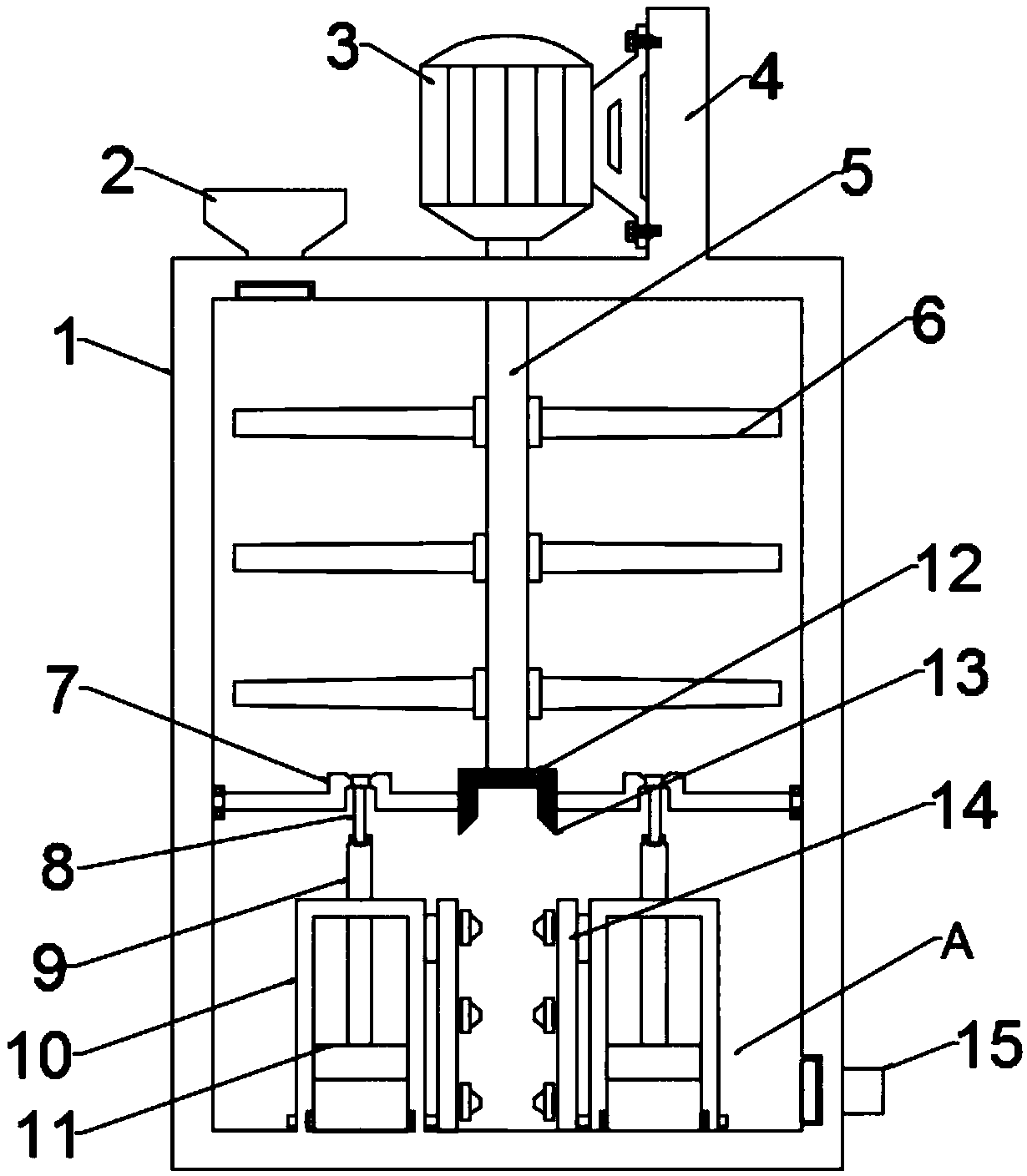

[0023] see figure 2 and 4 , in an embodiment of the present invention, a paint stirring device for a construction site includes a stirring chamber 1, a motor 3 and a pumping mechanism; the inner lower end of the stirring chamber 1 is symmetrically installed with a pumping mechanism, and the pumping mechanism includes a crankshaft 7 and a connecting rod 8 , push rod 9, piston cylinder 10, piston 11 and nozzle pipe 14, nozzle pipe 14 is provided with two symmetrically and is positioned at the inner side of two piston cylinders 10, piston cylinder 10 is communicated with nozzle pipe 14 by connecting pipe 22, nozzle pipe 14 A spray head is arranged on the piston cylinder 10, and a feeding pipe 23 is arranged at a position opposite to the connecting pipe 22 on the piston cylinder 10. A one-way valve is arranged in the connecting pipe 22 and the feeding pipe 23, and the mixture in the stirring chamber 1 Enter the piston cylinder 10 from the feed pipe 23, then enter the spray pipe ...

Embodiment 2

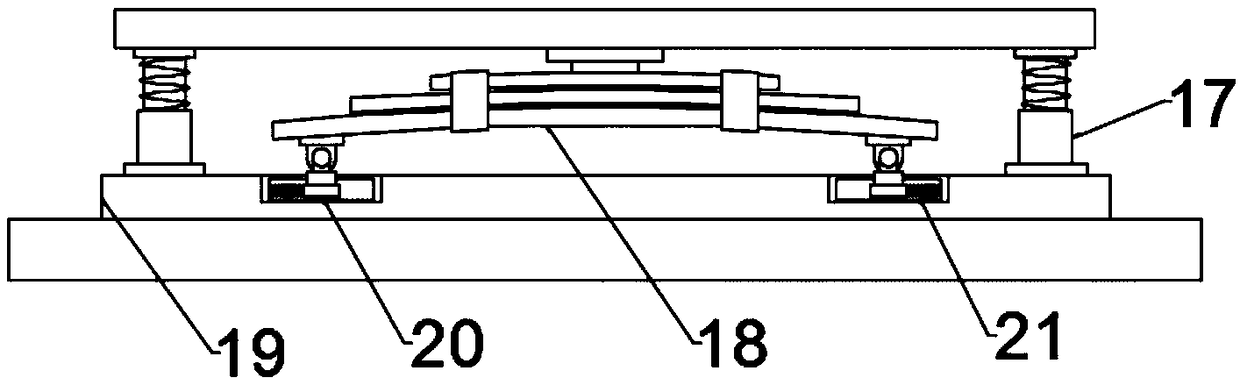

[0028] see figure 1 , 3 And 4, the difference between embodiment two and embodiment one is that the lower end of the stirring chamber 1 is equipped with a shock absorbing mechanism, which includes a fixed plate 16, a telescopic rod 17, a leaf spring 18, a bottom plate 19 and a slider 20, and the fixed The plate 16 is fixedly connected with the lower end of the stirring chamber 1, and the lower end of the fixed plate 16 is connected with the bottom plate 19 through a symmetrically arranged telescopic rod 17, the outer end of the telescopic rod 17 is provided with a spring, and the leaf spring 18 is arranged on two described On the inner side of the telescopic rod 17, the upper end of the leaf spring 18 is fixedly connected to the lower end of the fixed plate 16, and both sides of the lower end of the leaf spring 18 are hinged with symmetrically arranged sliders 20, and the slider 20 is slidably connected to the chute arranged on the bottom plate 19 Inside, the outer end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com