Method of preparing iron phthalocyanine (FePc) water-soluble dispersed nanoparticles

A nanoparticle, water-soluble technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as poor dispersion, intermolecular agglomeration, and reduced catalytic activity, and achieve improved effects, simple preparation methods, and improved agglomeration. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

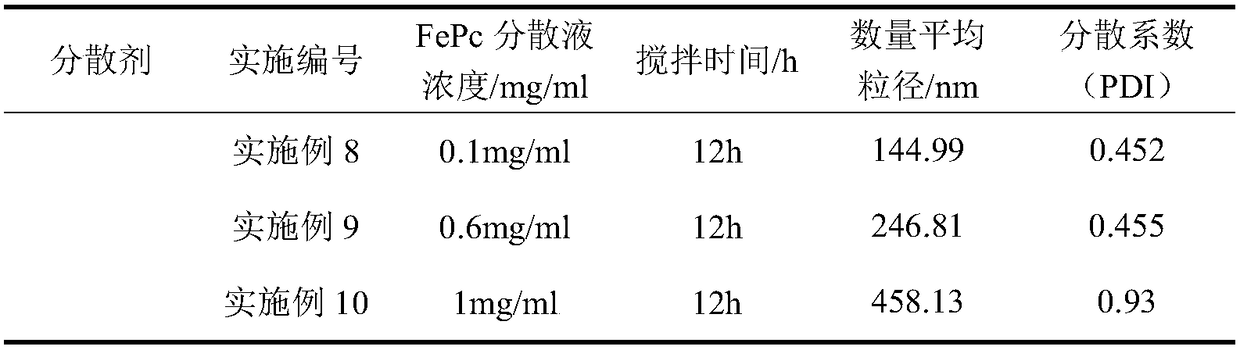

[0067] The concentration of 0.5% sodium dodecyl sulfate was modified to prepare water-soluble dispersed particles of iron phthalocyanine.

[0068] Weigh 7.2mg of iron phthalocyanine into a beaker, add 48ml of ethanol solution, and ultrasonically disperse iron phthalocyanine in the ethanol solution for 30min to prepare 0.15mg / ml iron phthalocyanine solution; weigh 60mg of Sodium lauryl sulfate is dispersed in 12ml deionized water to prepare a 0.5% aqueous solution, and 4 parts of the prepared iron phthalocyanine solution and 1 part of sodium lauryl sulfate dispersant aqueous solution are evenly mixed, and stirred in a constant temperature magnetic heating stirrer (setting stirring temperature is 25 ℃, stirring speed is 500rmp, and stirring time is 132h), until the solvent ethanol in the dispersion liquid evaporates completely, and utilizes the low-speed centrifuge to centrifuge the dispersion liquid that the solvent volatilizes completely (setting centrifugal speed is 5000rmp, ...

Embodiment 2

[0070] The concentration of 0.75% sodium dodecyl sulfate was modified to prepare water-soluble dispersed particles of iron phthalocyanine.

[0071] Weigh 7.2 mg of iron phthalocyanine into a beaker, add 48 ml of ethanol solution, and ultrasonically disperse iron phthalocyanine in the ethanol solution for 30 minutes to prepare a 0.15 mg / ml iron phthalocyanine solution; weigh 90 mg of Sodium lauryl sulfate is dispersed in 12ml of deionized water to prepare a 0.75% aqueous solution, and 4 parts of the prepared iron phthalocyanine solution and 1 part of sodium lauryl sulfate dispersant aqueous solution are evenly mixed, and stirred in a constant temperature magnetic heating stirrer (setting stirring temperature is 25 ℃, stirring speed is 500rmp, and stirring time is 60h), until the solvent ethanol in the dispersion liquid evaporates completely, and utilizes the low-speed centrifuge to centrifuge the dispersion liquid that solvent volatilization is complete (setting centrifugal spee...

Embodiment 3

[0073] The concentration of 1% sodium dodecyl sulfate was modified to prepare water-soluble dispersed particles of iron phthalocyanine.

[0074] Weigh 7.2 mg of iron phthalocyanine into a beaker, add 48 ml of ethanol solution, and ultrasonically disperse iron phthalocyanine in the ethanol solution for 30 minutes to prepare a 0.15 mg / ml iron phthalocyanine solution; weigh 120 mg of Sodium lauryl sulfate is dispersed in 12ml deionized water to prepare a 1% aqueous solution, and 4 parts of the prepared iron phthalocyanine solution and 1 part of sodium lauryl sulfate dispersant aqueous solution are evenly mixed, and stirred in a constant temperature magnetic heating stirrer (setting stirring temperature is 25 ℃, stirring speed is 500rmp, and stirring time is 72h), until the solvent ethanol in the dispersion liquid evaporates completely, and utilizes the low-speed centrifuge to centrifuge the dispersion liquid that solvent volatilization is complete (setting centrifugal speed is 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com