Axial differential-pressure heat-state internal-pressure forming method of special-shaped variable-cross-section pipe fitting

A technology for deformation and pipe fittings, which is applied in the field of axial differential pressure hot-state internal pressure forming of special-shaped and variable-section pipe fittings. The effect of controllable distribution, coordinated deformation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0039] Specific implementation mode one: see Figure 5 Note that the axial differential pressure thermal internal pressure forming method of a special-shaped cross-section pipe fitting in this embodiment is realized according to the following steps:

[0040] Step 1, heating the mold 2 to 150-500°C;

[0041] Step 2, put the original tube blank 3 into the hot mold, close the mold 2, and apply a certain clamping force;

[0042] Step 3, the punch 4 moves to contact and seal the tube blank 3, and then fills the inside of the tube blank 3 with a hot fluid medium 6 at 150-500°C through the internal pipeline 5;

[0043] Step 4. When the mold 2, the tube blank 3, and the fluid medium 6 reach the target temperature, start the supercharger that controls the internal pressure of the tube blank 3, and establish a certain initial pressure inside the tube blank 3. Under the action of this pressure, the tube blank 3 The transition area 7 between the axial areas of the billet 3 is closely at...

specific Embodiment approach 2

[0047] Specific implementation mode two: see Image 6 Explain that the difference between this embodiment and the specific embodiment 1 is that in the axial differential pressure hot state internal pressure forming method for special-shaped variable cross-section pipe fittings in this embodiment, there is no transition section on the final required pipe fitting that can be first bonded to the mold , so it is necessary to add a device on the mold or the tube blank that can separate the two areas with different cross-sections, so that there is a transition area 7 between the areas of the tube blank 3. In this embodiment, the mold at the junction of the two adjacent areas The movable insert 9 is set to be movable, corresponding to the transition area 7 of the tube blank 3. In step 4, the movable insert 9 is driven by the external force F to move to the inside of the cavity to form a shape with a small cross-sectional area. Under the action of the initial pressure, the tube blank ...

specific Embodiment approach 3

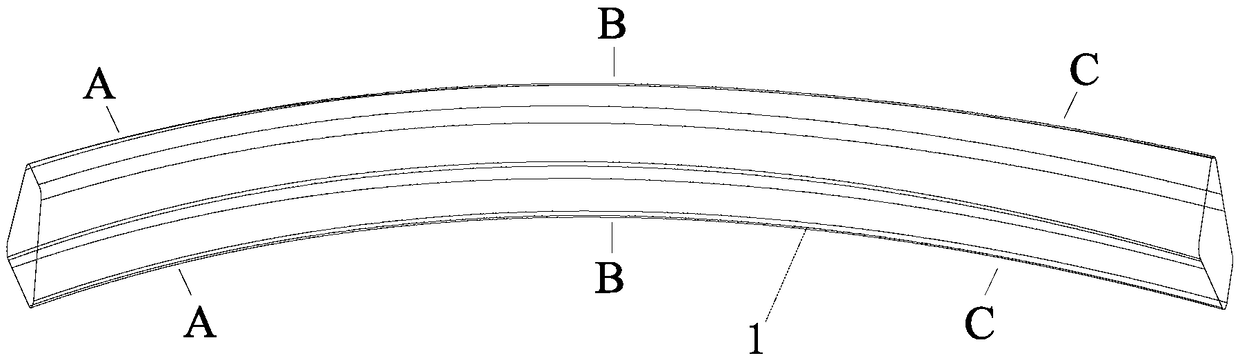

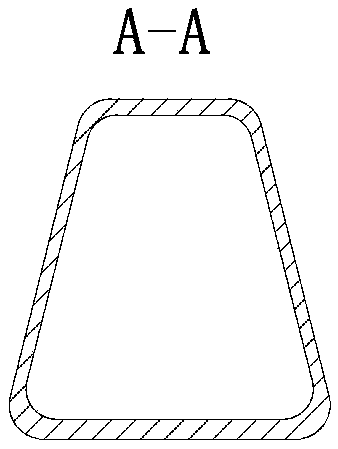

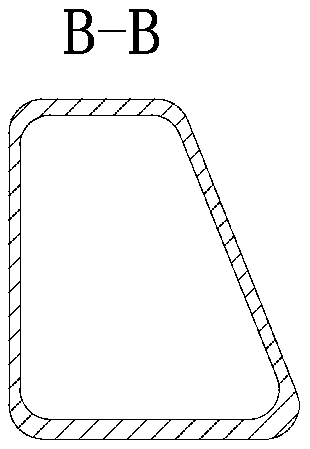

[0049] Specific implementation mode three: see Figure 7 and Figure 8 Note, the difference between this embodiment and the specific embodiment 1 or 2 is: a hot internal pressure forming method using axial differential pressure in this embodiment, in step 2, the original metal tube blank is 6061 aluminum alloy seamless The tube blank or AZ31 magnesium alloy tube blank has a wall thickness of 1.0-5.0mm, an outer diameter of 20-60mm, and a non-circular cross-sectional shape such as trapezoid or rectangle.

[0050] As a preference, the original tube blank 3 can be prepared by filling the inside of the circular tube blank with 2-10 MPa gas or liquid and then closing the molds.

[0051] In this embodiment, according to the different structural features of the final pipe fittings, different initial shapes of the pipe blanks are used, which can effectively control the wall thickness distribution of the formed special-shaped variable cross-section pipe fittings and obtain higher shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com