Flexible welding jig used for thin-walled cylinder type magnetic material parts

A magnetic material, thin-walled cylinder technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The effect of stable, convenient welding operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

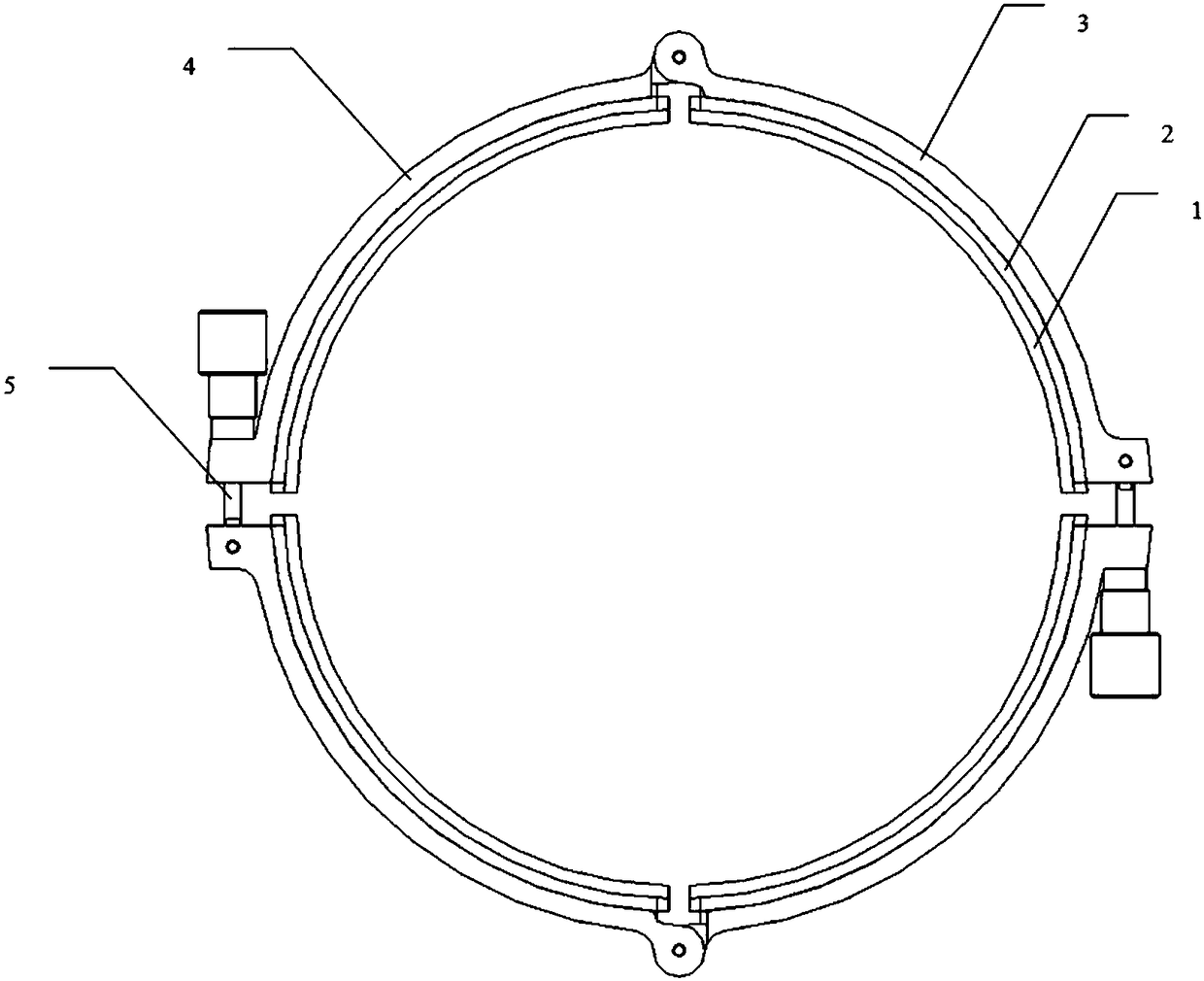

[0024] Such as figure 1 As shown, the two opposite locking screws 5 are adjusted to make the screw-in depths different, so as to realize the clamping of parts with different outer diameters.

[0025] The invention solves the influence of clamping on the surface quality and magnetic properties of thin-walled magnetic materials during the processing process, and can play an orthopedic role after clamping. During operation, only need to follow the specified steps to basically eliminate the influence of part deformation on magnetic properties, which is fast and convenient. Only one person can complete the clamping, and one clamping can realize continuous operation, which directly improves the work efficiency by more than three times, and the processing pass rate reaches 100%. It can be extended to the welding process of all cylindrical thin-walled magnetic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com