Machining process of heavy truck casting cross beam

A truck and machining technology, which is applied in the field of mechanical parts processing technology, can solve the problems of not being able to meet the loading requirements of the assembly site, complicated mechanical processing technology, and a lot of manpower and equipment, so as to achieve reasonable utilization and manpower occupation And less equipment, the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing, the present invention is described in further detail:

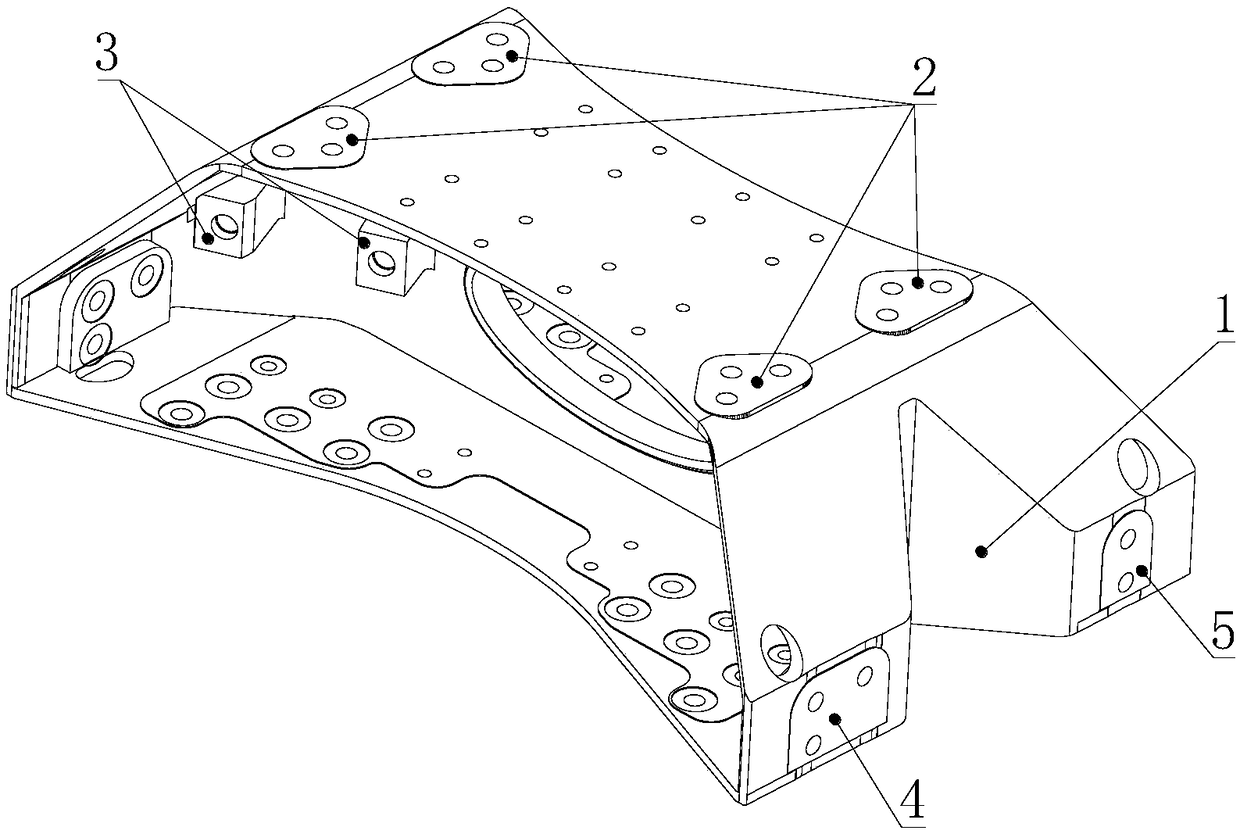

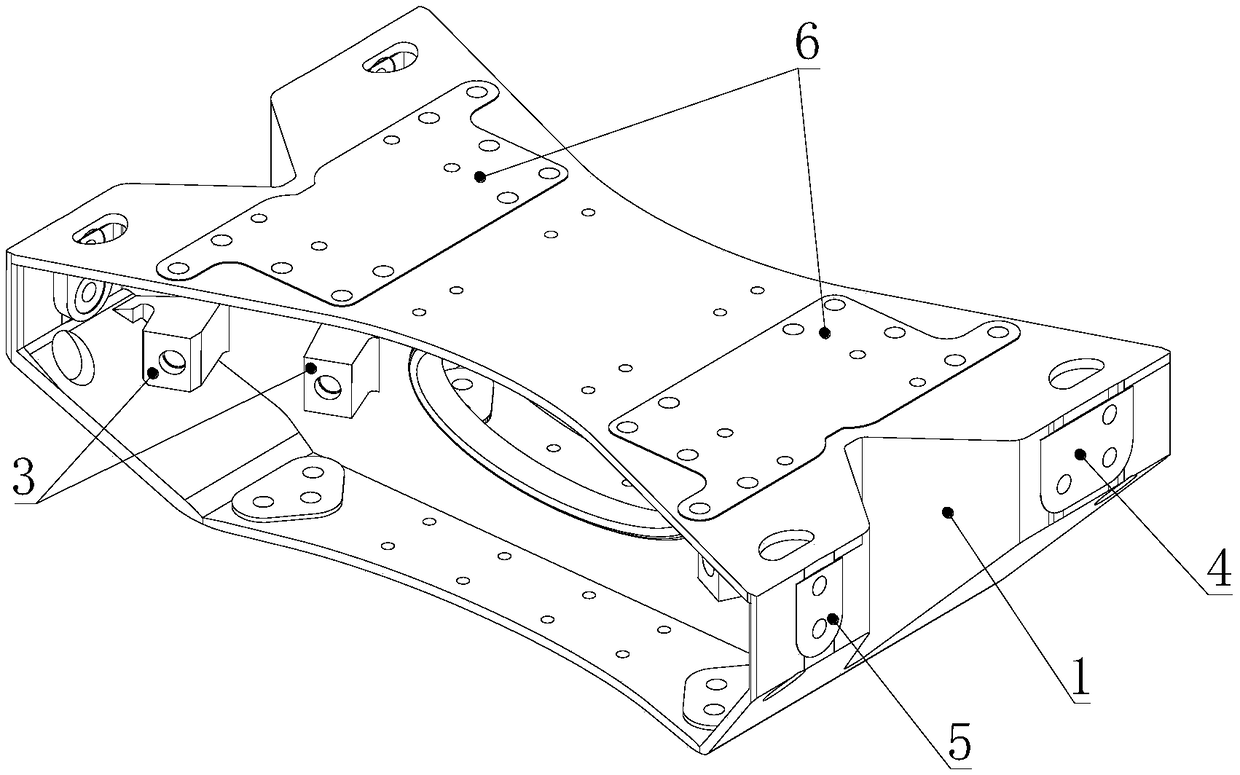

[0056] Such as Figure 1-2 Shown, a kind of machining process of heavy-duty truck cast beam, comprises the following steps:

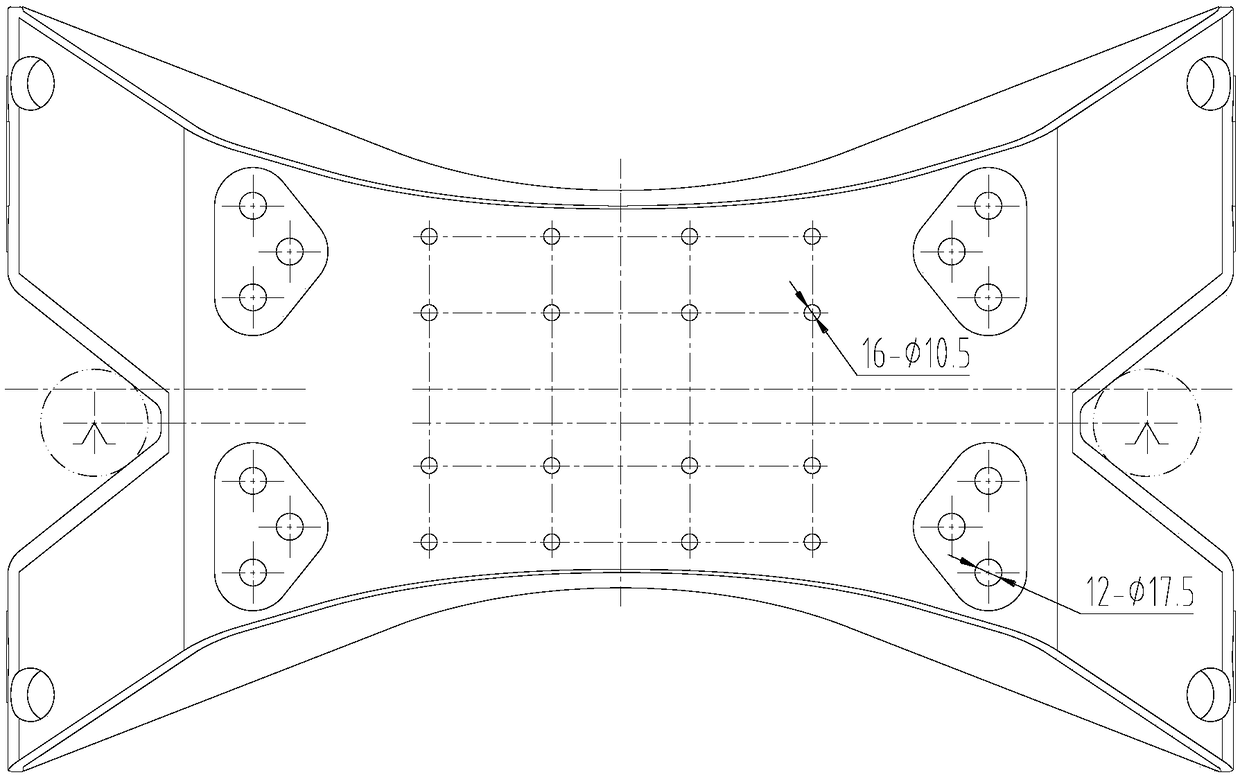

[0057]S1. Top surface processing: locate with the positioning grooves 1 on both sides of the cast beam, and fix the cast beam through three fixed points and one auxiliary fixed point on the bottom surface; process the upper reference plane 2 of the cast beam, and process Φ17. 5 holes and Φ10.5 holes; as the first processing surface of the entire workpiece, the rough surface of the bottom surface is used as the reference for processing. Since the bottom surface is a rough surface, there may be unevenness. Three fixed points and one adjustable The height of the auxiliary fixed point is used for positioning, which can level the cast beam and ensure the processing accuracy of the upper reference plane 2;

[0058] Such as image 3 As shown, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com