Automatic drilling tapping machine and working method thereof

A technology of tapping machine and drilling rig, which is applied to other manufacturing equipment/tools, manufacturing tools, metal processing equipment, etc., to achieve the effects of ensuring smoothness, liberating manpower, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

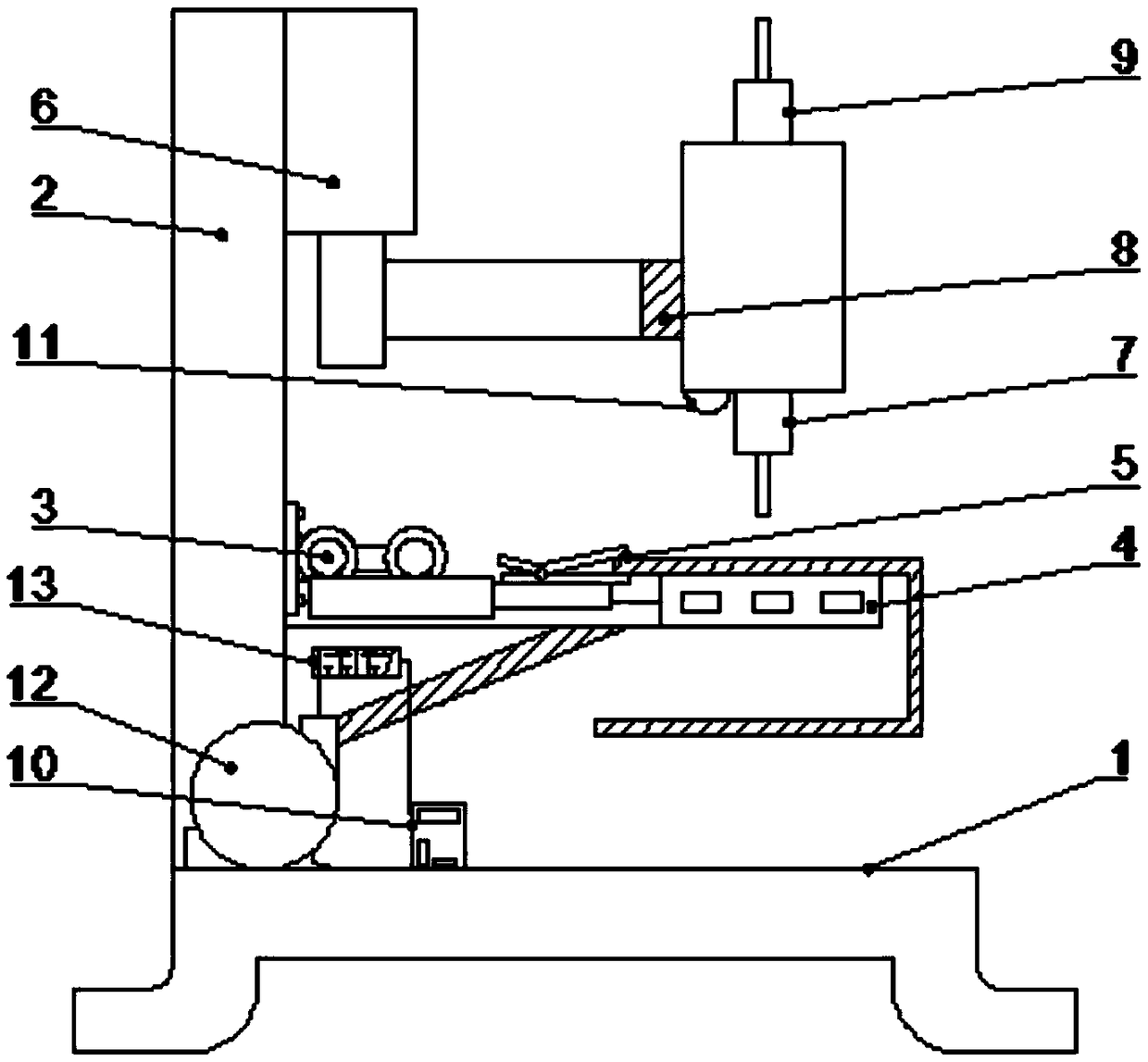

[0039] Such as figure 1 The shown automatic drilling and tapping machine is characterized in that it includes: a base 1, a bracket 2, a horizontal pneumatic mechanism 3, a support platform 4, a positioning clamp 5, a vertical pneumatic mechanism 6, a drilling machine 7 and a control mechanism. The base 1 is provided with a support 2, the middle section of the support 2 is provided with a horizontal pneumatic mechanism 3 and a support platform 4, the horizontal pneumatic mechanism 3 is arranged above the support platform 4, and the horizontal pneumatic mechanism 3 is provided with a positioning clip 5. The support platform 4 is provided with a through hole, the upper end of the support 2 is provided with a vertical pneumatic mechanism 6, and the vertical pneumatic mechanism 6 is provided with a drilling rig 7, and the control mechanism is connected to control the horizontal pneumatic mechanism 3 and the vertical pneumatic mechanism. Movement of body 6.

[0040] In this embodim...

Embodiment 2

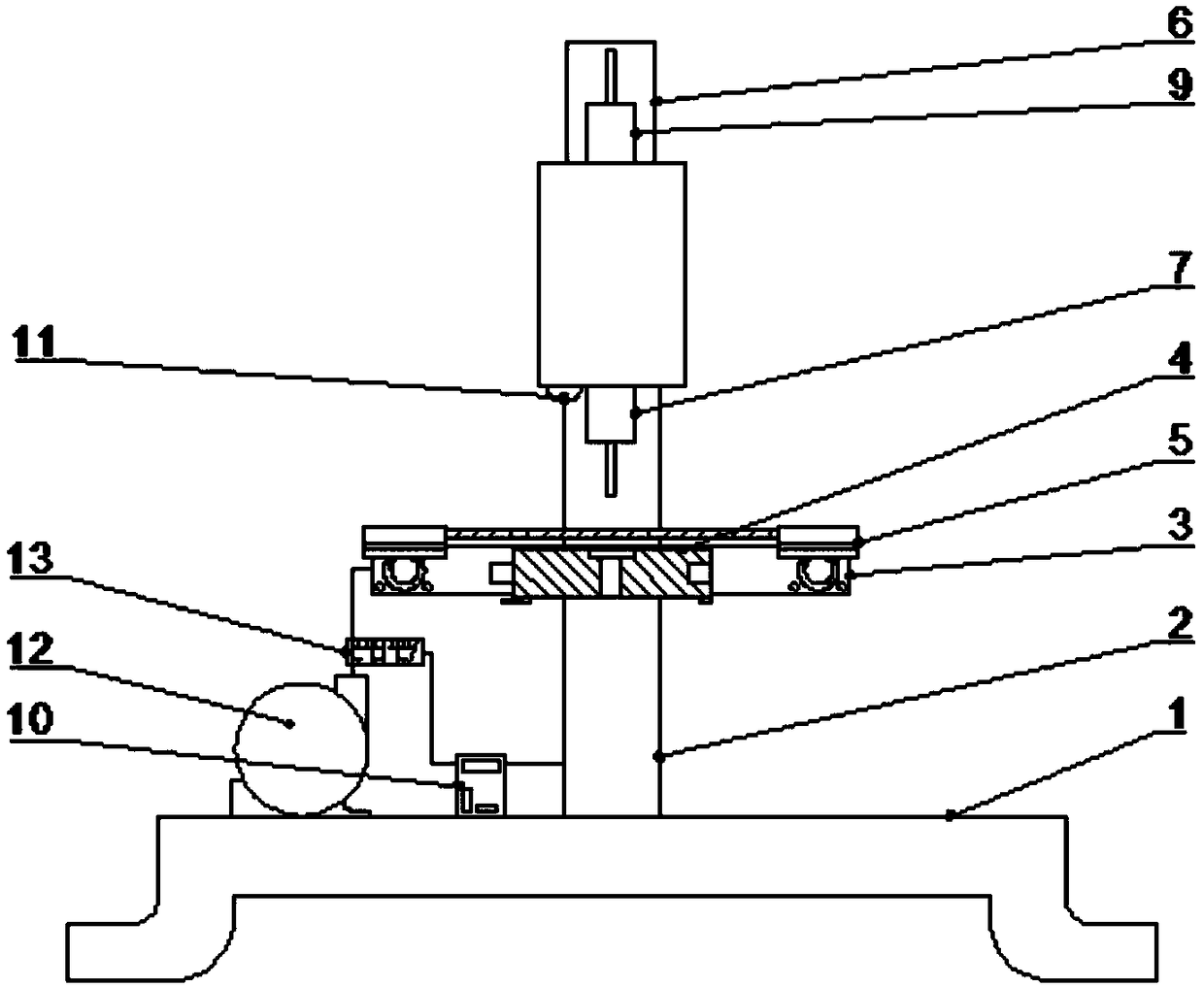

[0048] Such as figure 2 The shown automatic drilling and tapping machine is characterized in that it includes: a base 1, a bracket 2, a horizontal pneumatic mechanism 3, a support platform 4, a positioning clamp 5, a vertical pneumatic mechanism 6, a drilling machine 7 and a control mechanism. The base 1 is provided with a support 2, the middle section of the support 2 is provided with a horizontal pneumatic mechanism 3 and a support platform 4, the horizontal pneumatic mechanism 3 is arranged above the support platform 4, and the horizontal pneumatic mechanism 3 is provided with a positioning clip 5. The support platform 4 is provided with a through hole, the upper end of the support 2 is provided with a vertical pneumatic mechanism 6, and the vertical pneumatic mechanism 6 is provided with a drilling rig 7, and the control mechanism is connected to control the horizontal pneumatic mechanism 3 and the vertical pneumatic mechanism. Movement of body 6.

[0049] In this embodi...

Embodiment 3

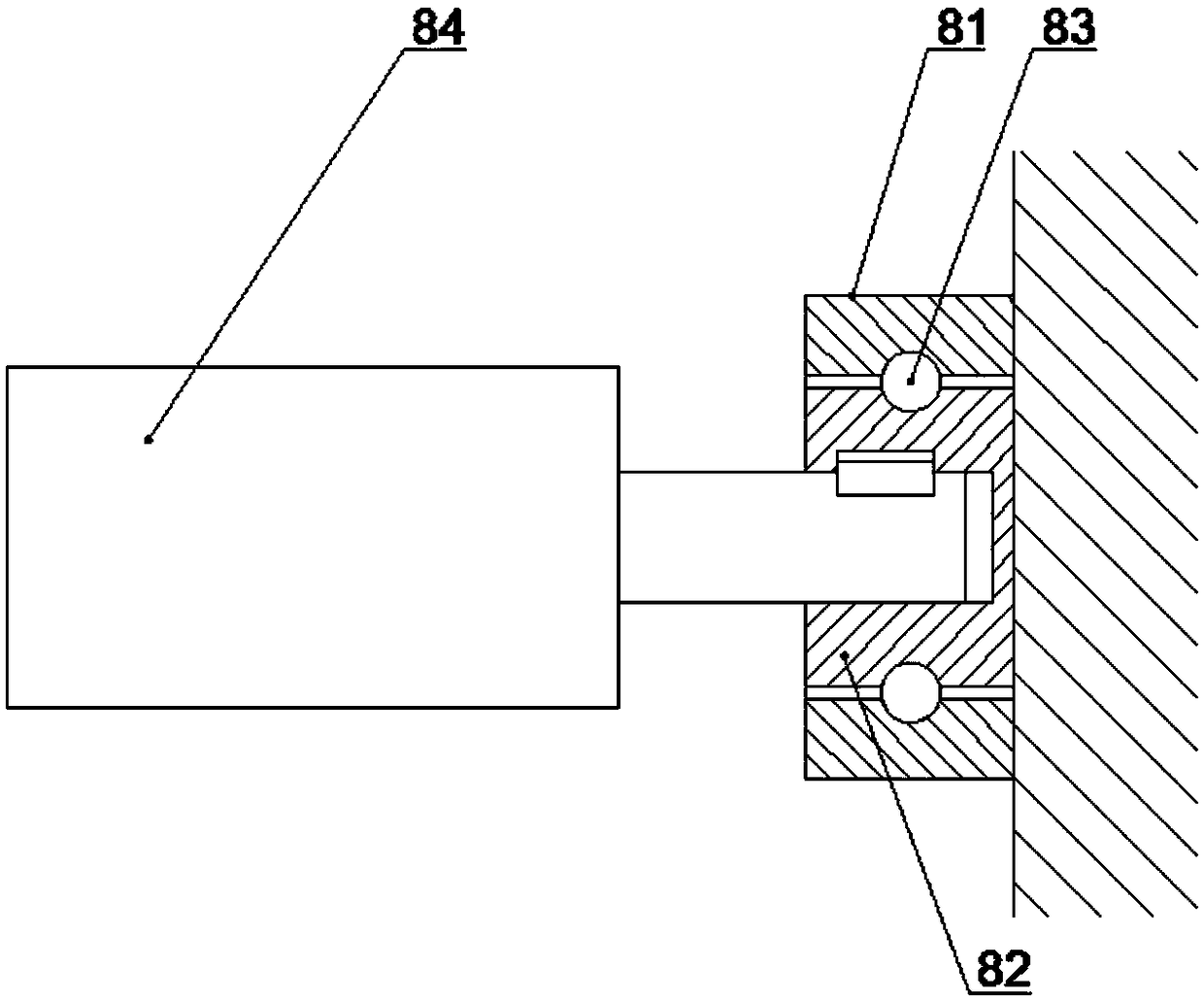

[0060] Such as image 3 The shown automatic drilling and tapping machine is characterized in that it includes: a base 1, a bracket 2, a horizontal pneumatic mechanism 3, a support platform 4, a positioning clamp 5, a vertical pneumatic mechanism 6, a drilling machine 7 and a control mechanism. The base 1 is provided with a support 2, the middle section of the support 2 is provided with a horizontal pneumatic mechanism 3 and a support platform 4, the horizontal pneumatic mechanism 3 is arranged above the support platform 4, and the horizontal pneumatic mechanism 3 is provided with a positioning clip 5. The support platform 4 is provided with a through hole, the upper end of the support 2 is provided with a vertical pneumatic mechanism 6, and the vertical pneumatic mechanism 6 is provided with a drilling rig 7, and the control mechanism is connected to control the horizontal pneumatic mechanism 3 and the vertical pneumatic mechanism. Movement of body 6.

[0061] The vertical pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com