Pneumatic extrusion type automatic efficient and accurate controllable sugarcane seed cutting machine

A squeeze-type seed cutting machine technology, applied in seed and rhizome treatment, metal processing, application, etc., can solve the problems of straight cutting blade, affecting sugarcane planting, sugarcane incision cracking, etc., to improve germination rate, Good human-machine cooperation relationship, reducing the effect of extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further illustrate the present invention.

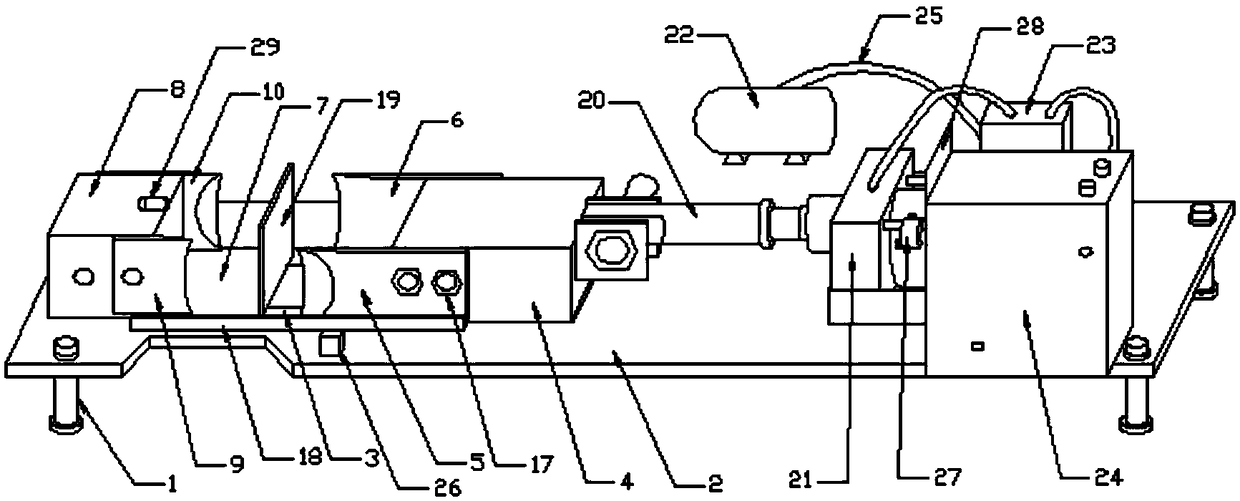

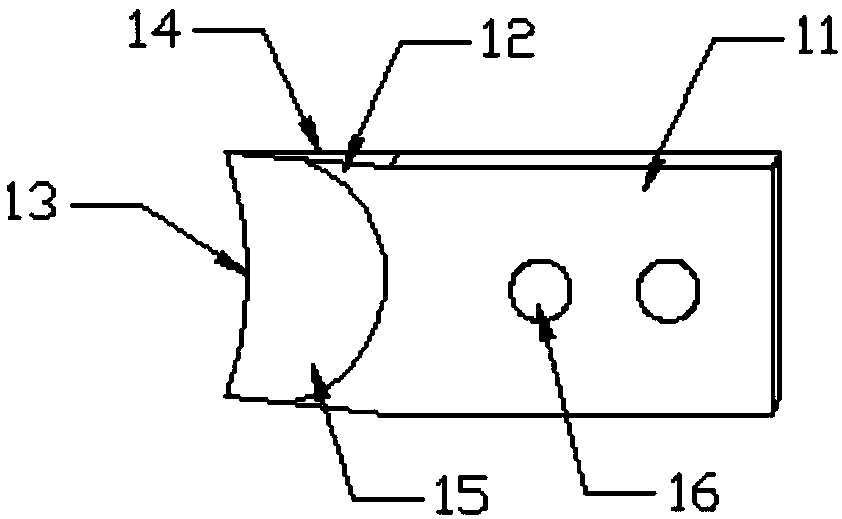

[0023] like Figure 1-2 As shown, a pneumatic extrusion type automatic, efficient, precise and controllable sugarcane seed cutter includes a support plate 2 with a foot 1, a cutting knife and a reciprocating drive device.

[0024] Described support plate 2 is provided with chute 3, and described chute 3 is provided with slide block 4, and described slide block 4 one end is connected with reciprocating driving device, and the both sides of the other end are respectively provided with first cutting knife 5 and The second cutting knife 6. The support plate 2 on the outside of the chute 3 ends is successively provided with a seed outlet 7 and a fixed block 19, and the support plate 2 at the chute 3 ends and near the end of the seed outlet 7 is provided with a vertical positioning block 8, and the positioning The width of the stopper is smaller than the width of the fixed block. A t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com