Spraying vehicle for glass fiber reinforcement cement product forming

A technology for strengthening cement and glass fiber, which is applied in the field of spraying vehicles, can solve the problems of slow research on molding equipment, difficult quality control, and low efficiency, and achieve the effects of improving efficiency, reducing labor force, and accelerating drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

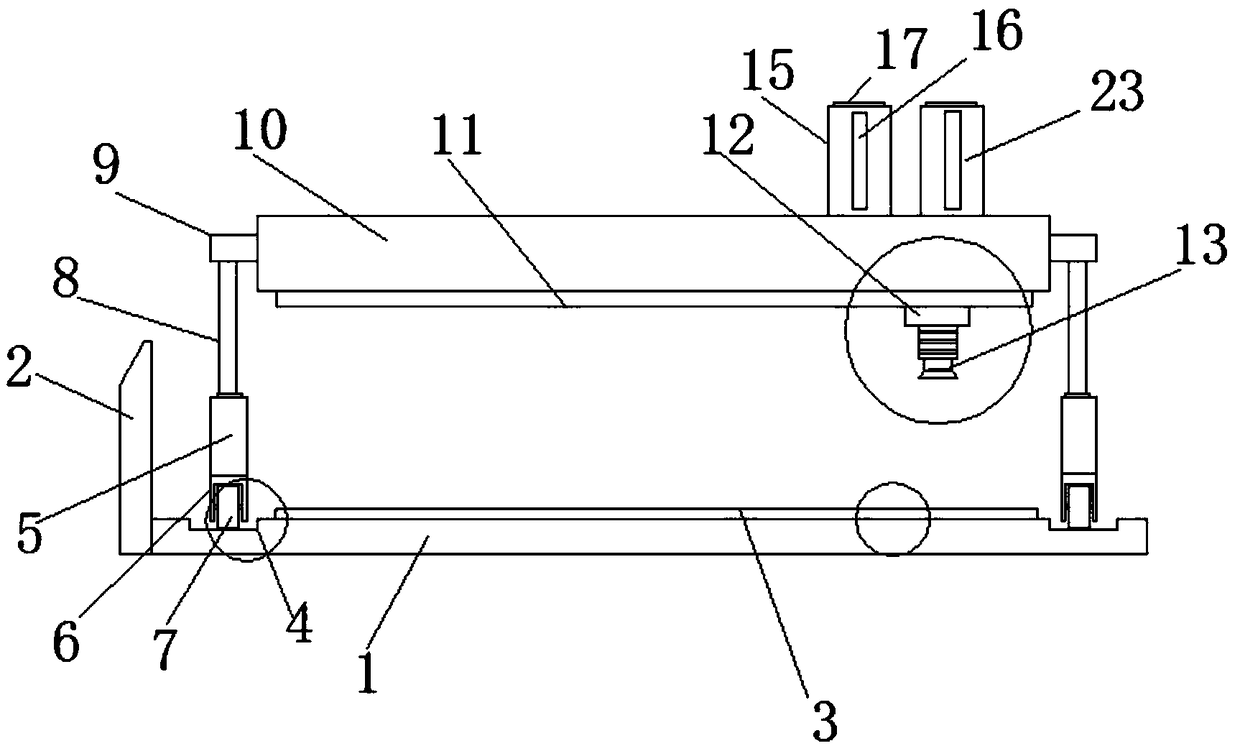

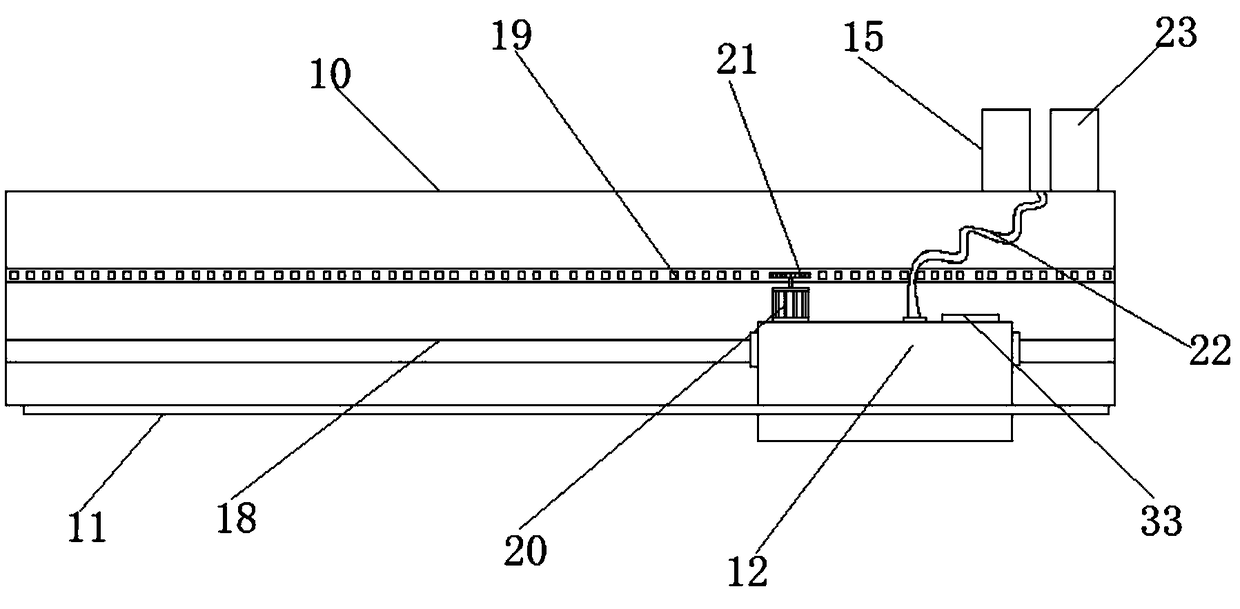

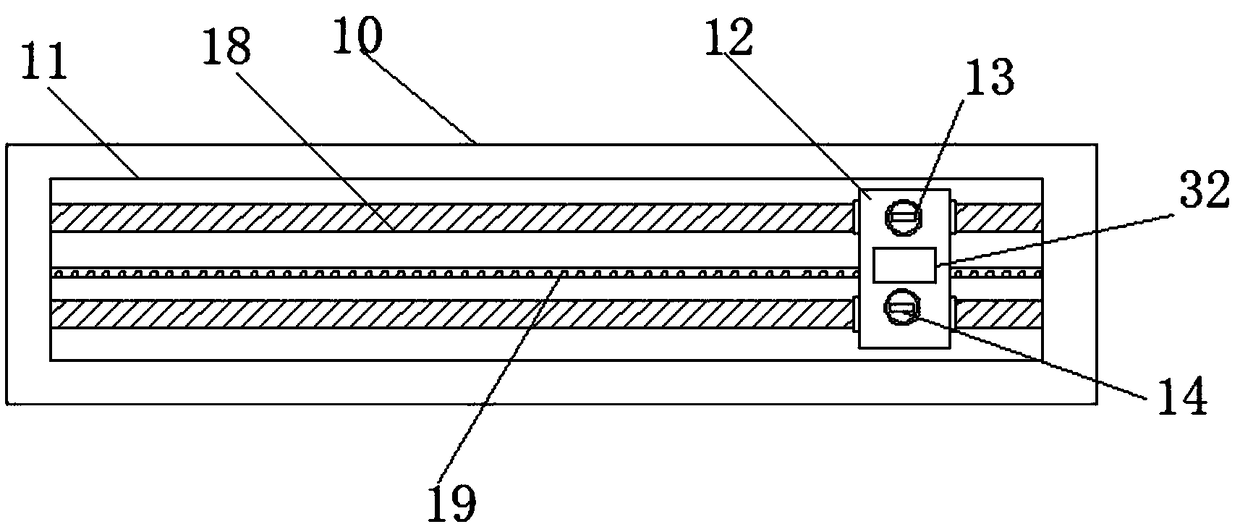

[0030] see Figure 1-8 , the present invention provides a technical solution: a jetting vehicle for forming glass fiber reinforced cement products, including a base plate 1, the top of the base plate 1 is provided with a roller groove 3 and a track groove 4, and the track groove 4 is provided with two groups, so Described roller groove 3 is positioned between two groups of track grooves 4, and the inner wall of described roller groove 3 is equipped with turning roller 28, and described turning roller 28 is evenly installed with multiple groups, and template 37 is placed on turning roller 28, and described substrate The left end of 1 is fixed with control box 2, and the inside of described rail groove groove 4 is placed with roller 7, and described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com