Digital printing equipment using ceramic powder

A digital printing and ceramic powder technology, applied in the field of digital printing, can solve the problems of low precision, mixing materials, and blurred brick surface patterns, etc., and achieve the effects of efficient use of space, simplified gas path connection, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

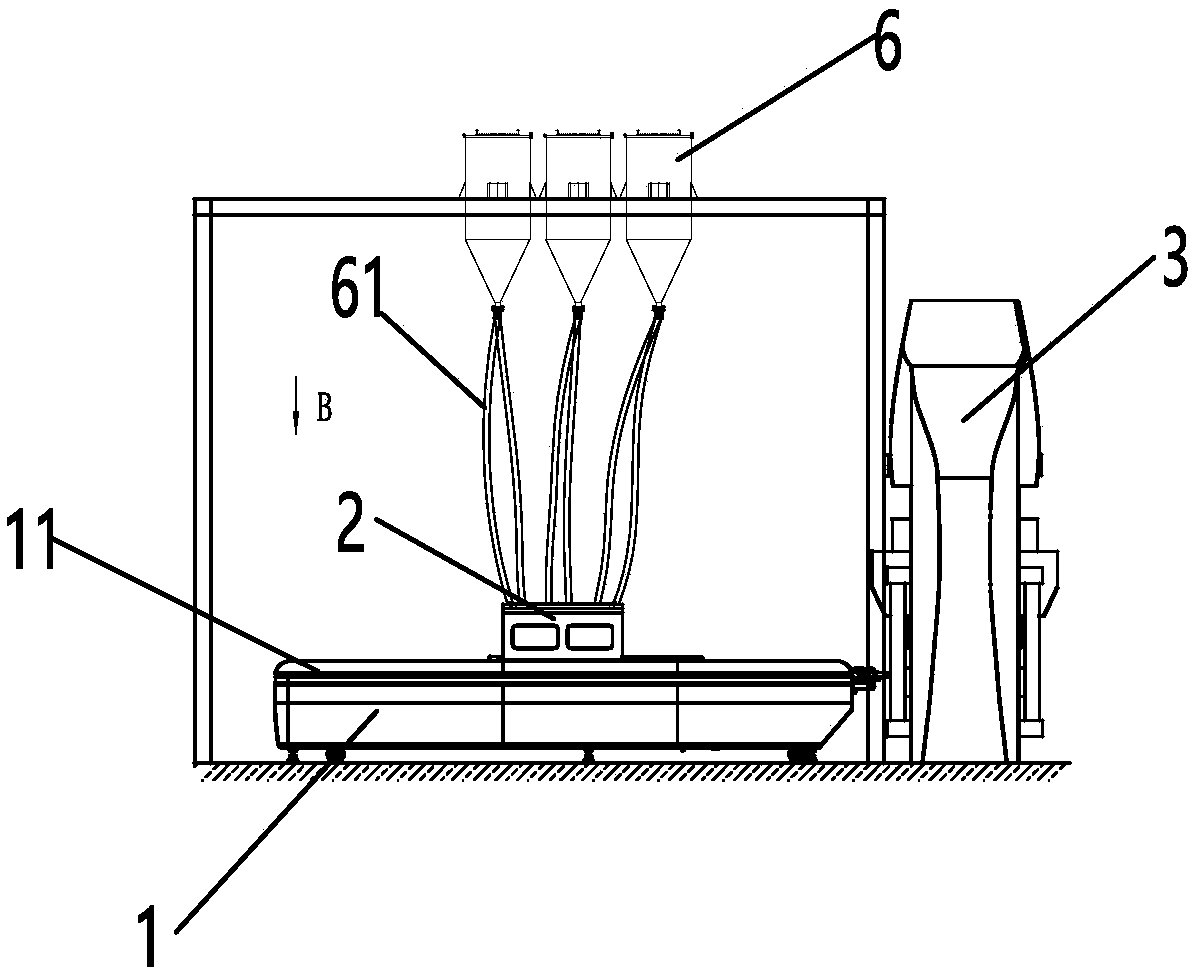

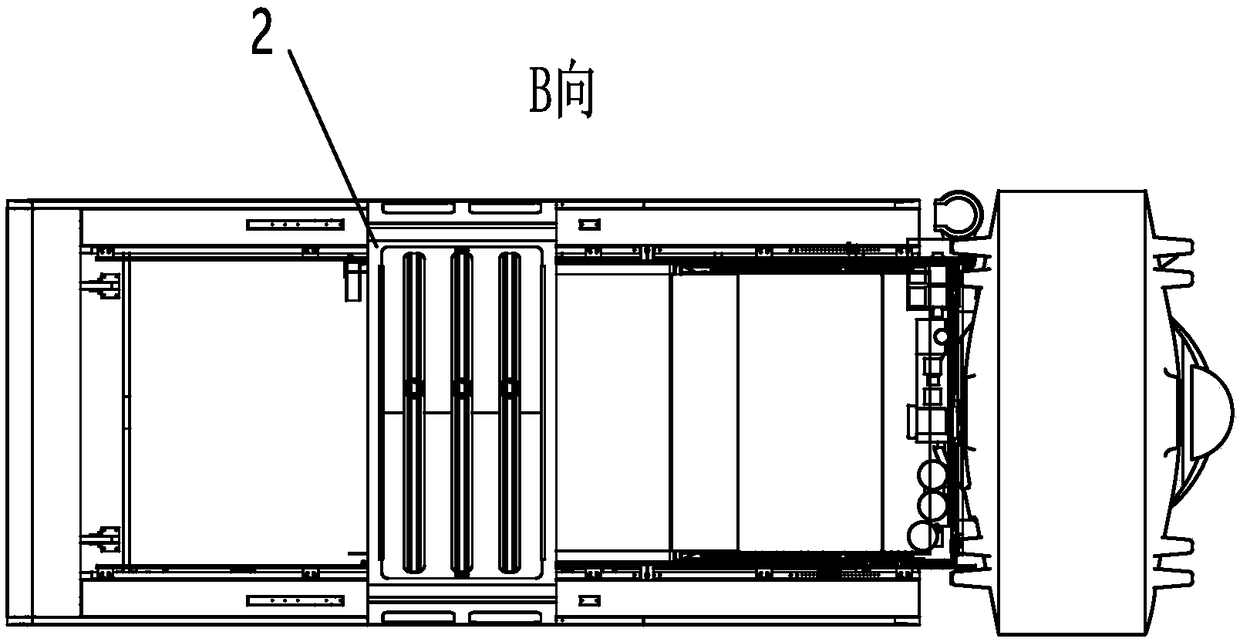

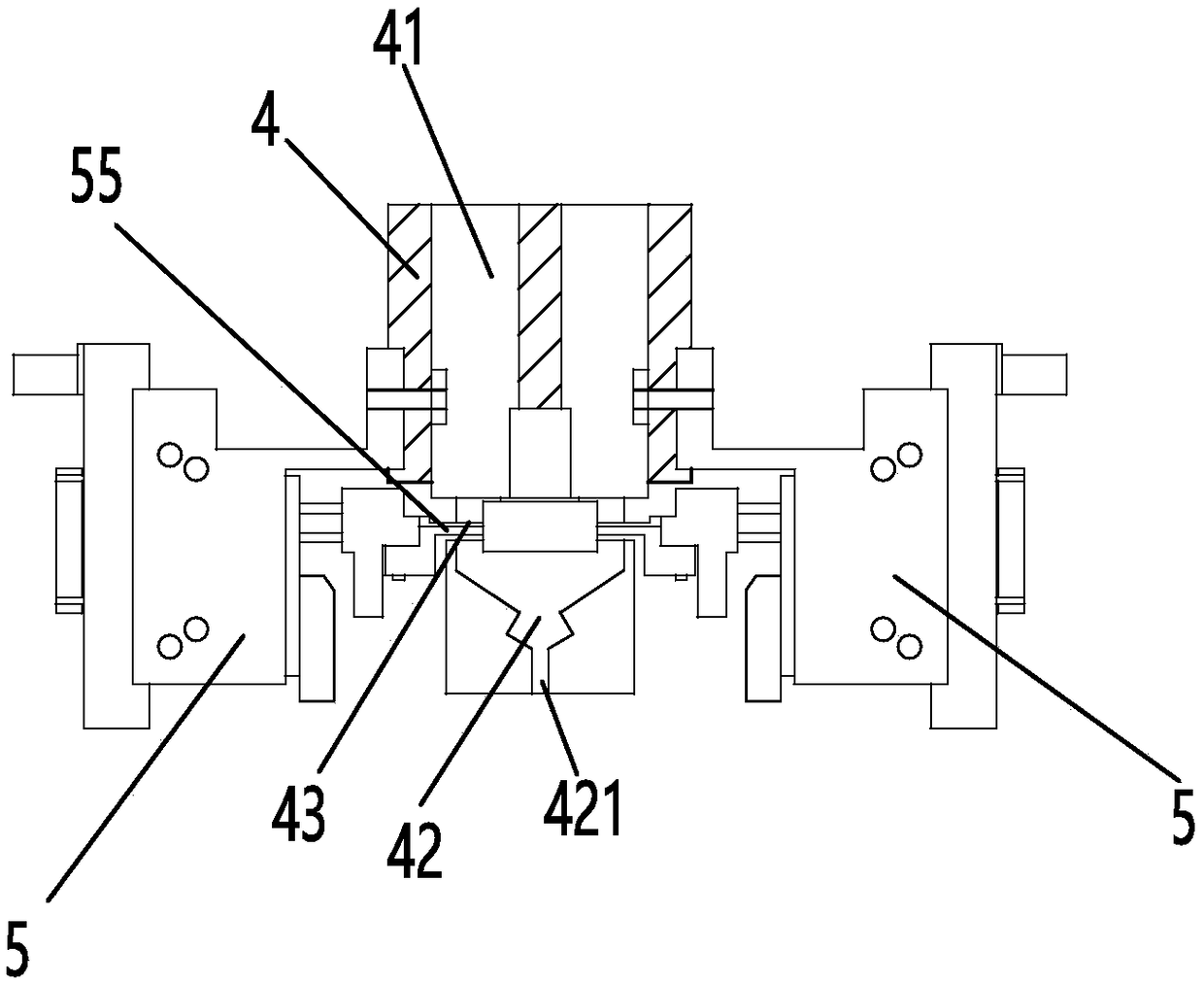

[0022] refer to figure 1 , figure 2 , image 3 and Figure 4 , a digital printing device using ceramic powder, including a base 1, a blanking mechanism 2, and a control device 3, the base 1 includes a conveying device 11; the blanking mechanism 2 is installed above the conveying device 11, The blanking mechanism 2 includes a hopper 4 and an integrated pneumatic device 5 that controls the blanking of the hopper 4; the hopper 4 includes a storage chamber 41 for storing powder, and is located below the storage chamber 41 The fu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap