Method for prefabricating concrete cracks and reinforcement corrosion defects in complete reinforced concrete foundation structure

A technology of reinforced concrete and prefabricated concrete, which is applied in infrastructure engineering, manufacturing tools, ceramic forming machines, etc., can solve problems such as incompleteness, and achieve the effects of simple tools, elimination of incompleteness, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

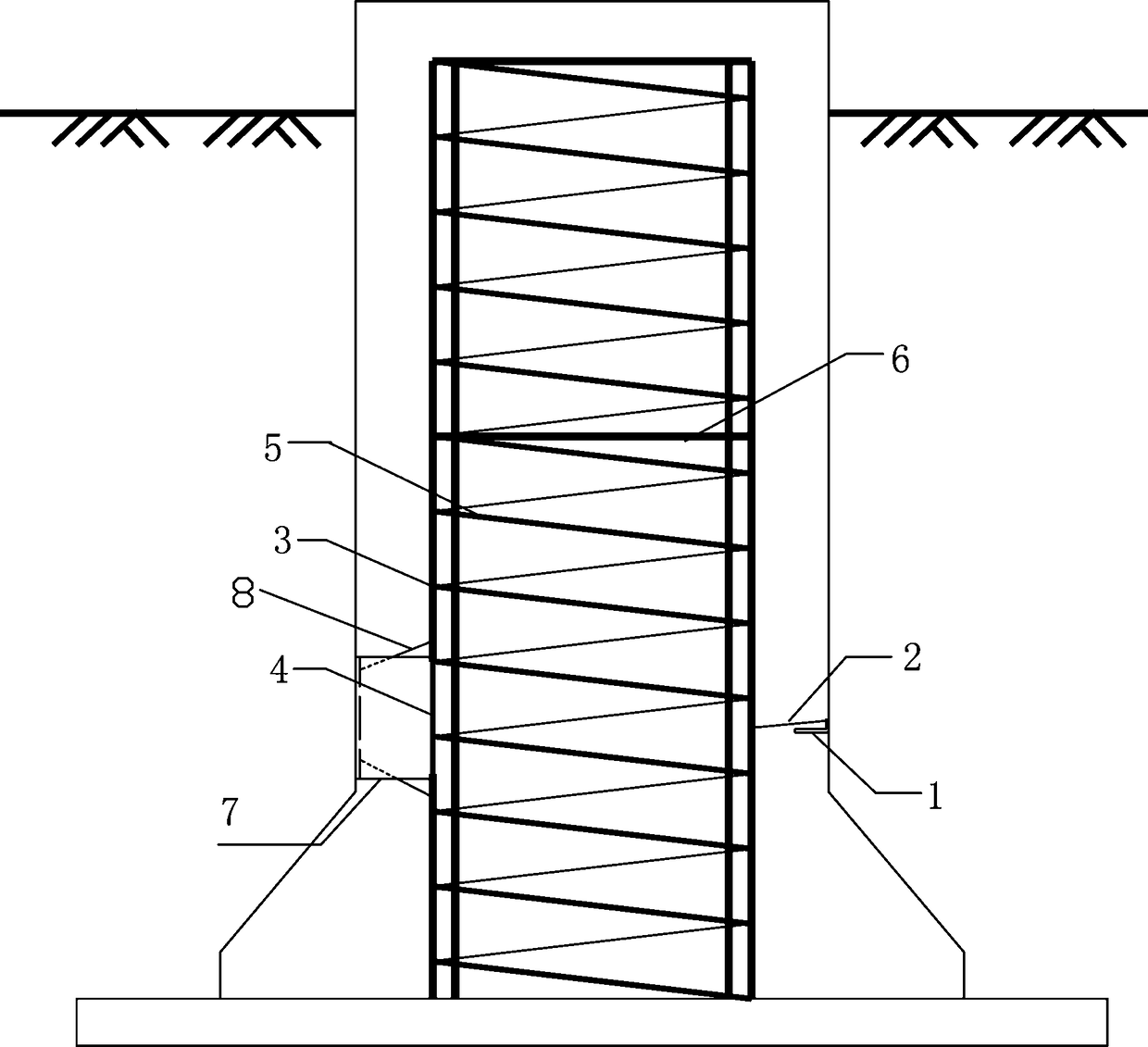

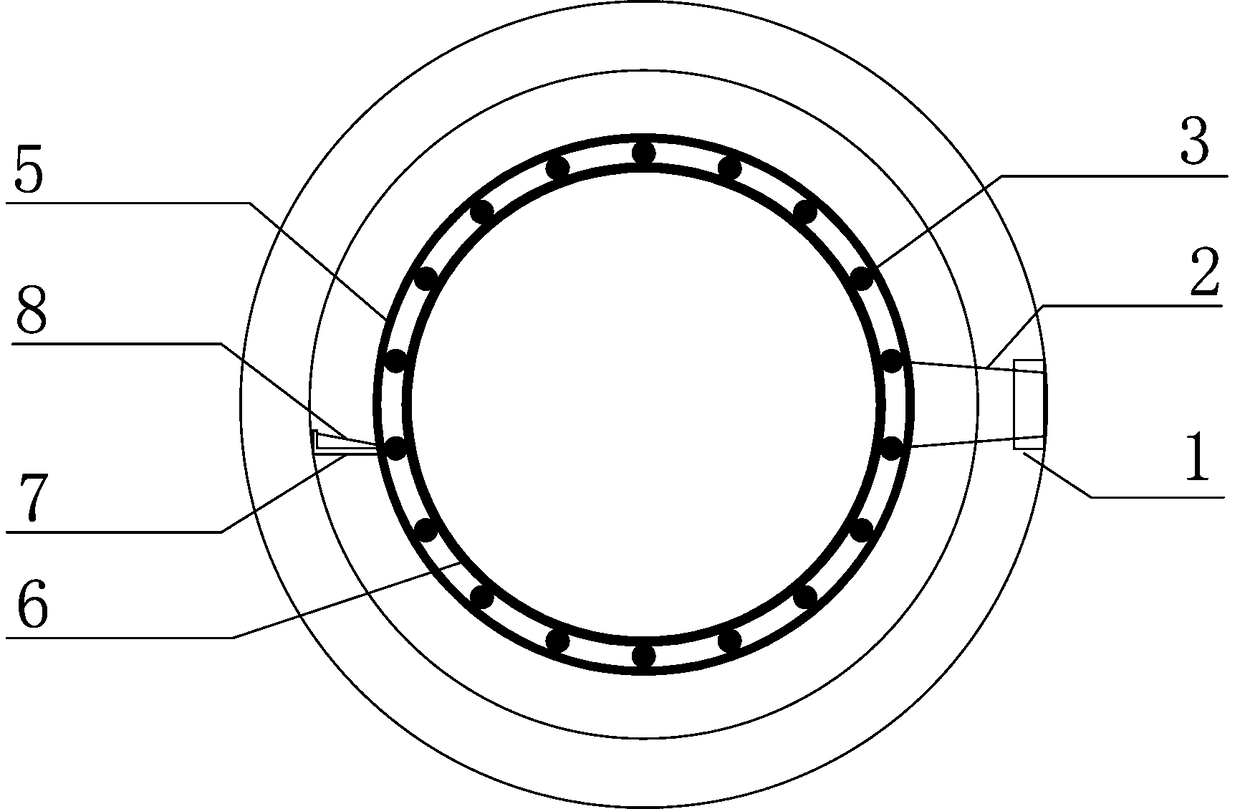

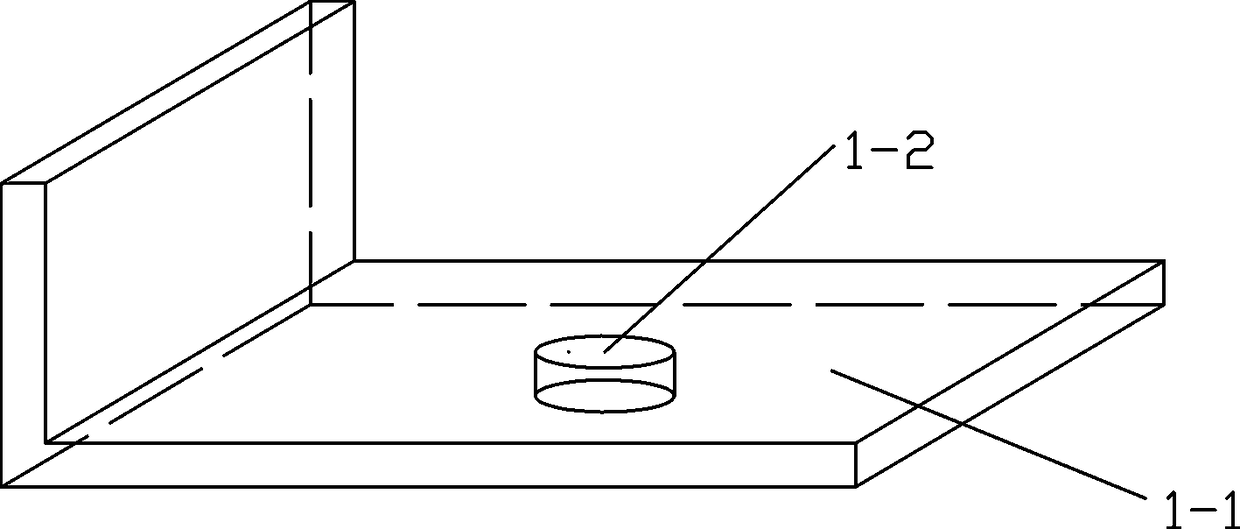

[0029] Such as Figure 1-Figure 4 As shown, a method for prefabricating concrete cracks and reinforcement corrosion defects in a complete reinforced concrete foundation structure, the method includes the following steps:

[0030] Step 1: Mark the location of the corroded reinforcement on the bound reinforcement cage, and cut and intercept the longitudinal reinforcement 3 of the reinforcement cage according to the required corrosion length (the reinforcement cage consists of longitudinal reinforcement 3, spiral outer stirrup 5 and inner 6 stirrups, the concrete foundation is made after concrete pouring);

[0031] Step 2: Fixedly connect the two ends of the simulated corrosion-defective steel bar section 4 of corresponding length to the truncated part of the longitudinal steel bar 3 of the steel bar cage. The connection method is electroslag pressure welding. After the steel bar is cooled after the connection is completed, the residual welding slag on the steel bar is removed; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com