Texturing cutting device for producing monocrystalline silicon pieces

A monocrystalline silicon wafer and cutting device technology, which is applied in the field of texturing and cutting devices for producing monocrystalline silicon wafers, can solve the problems of reduced work efficiency, low work efficiency, and high labor intensity, and achieve improved work efficiency and low manufacturing costs , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

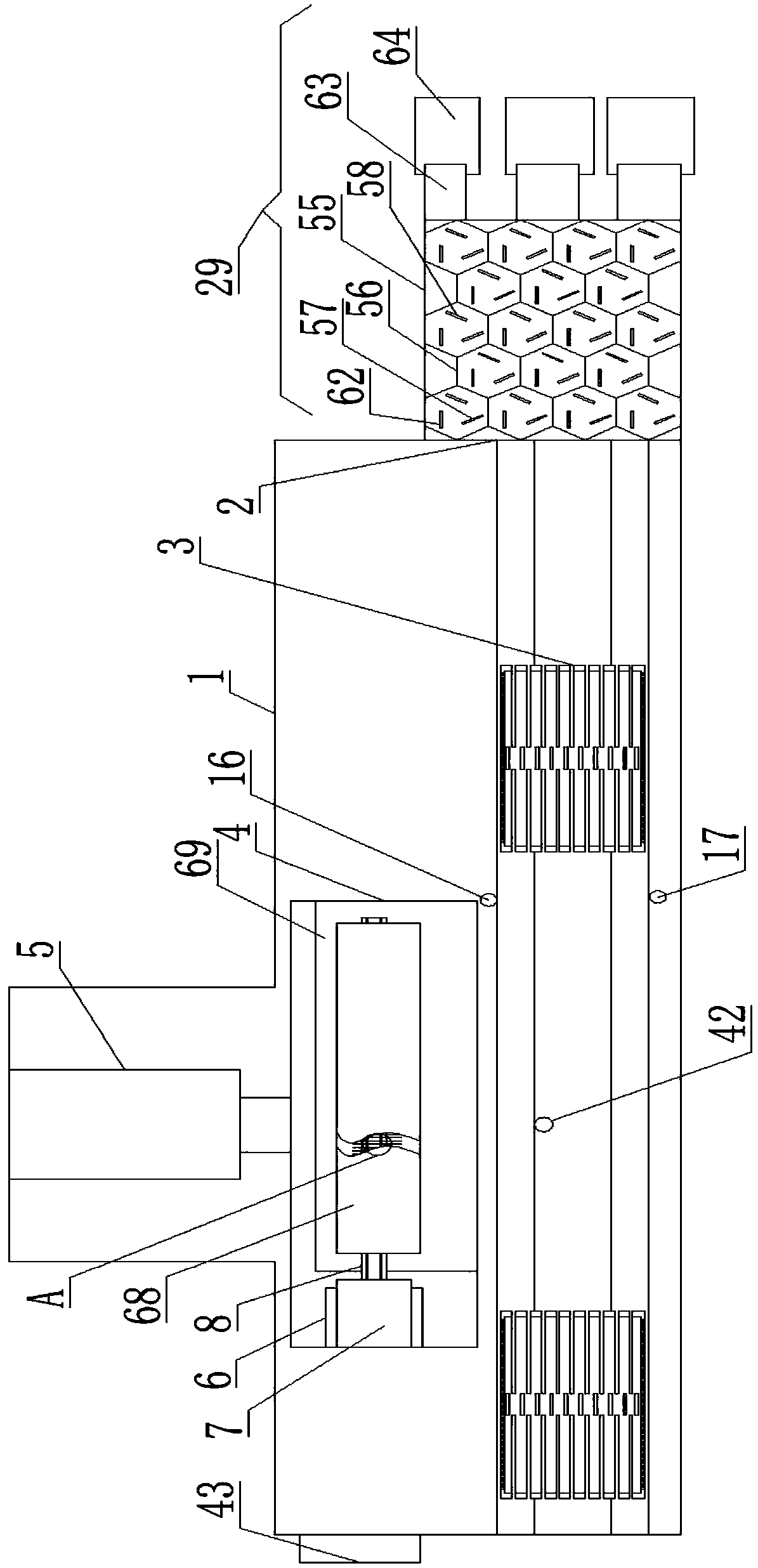

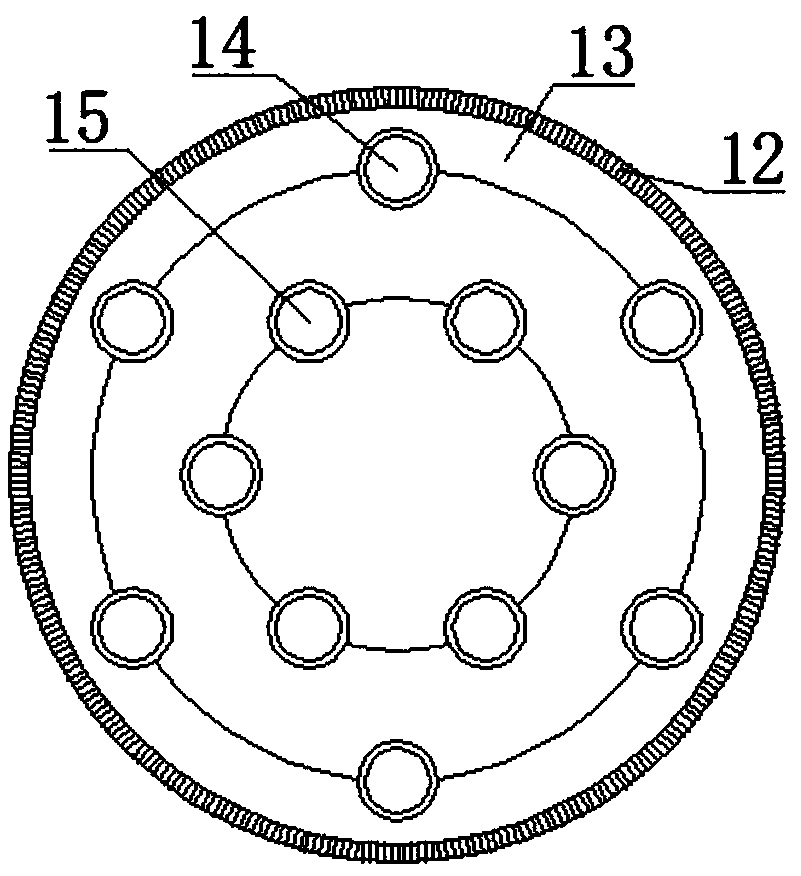

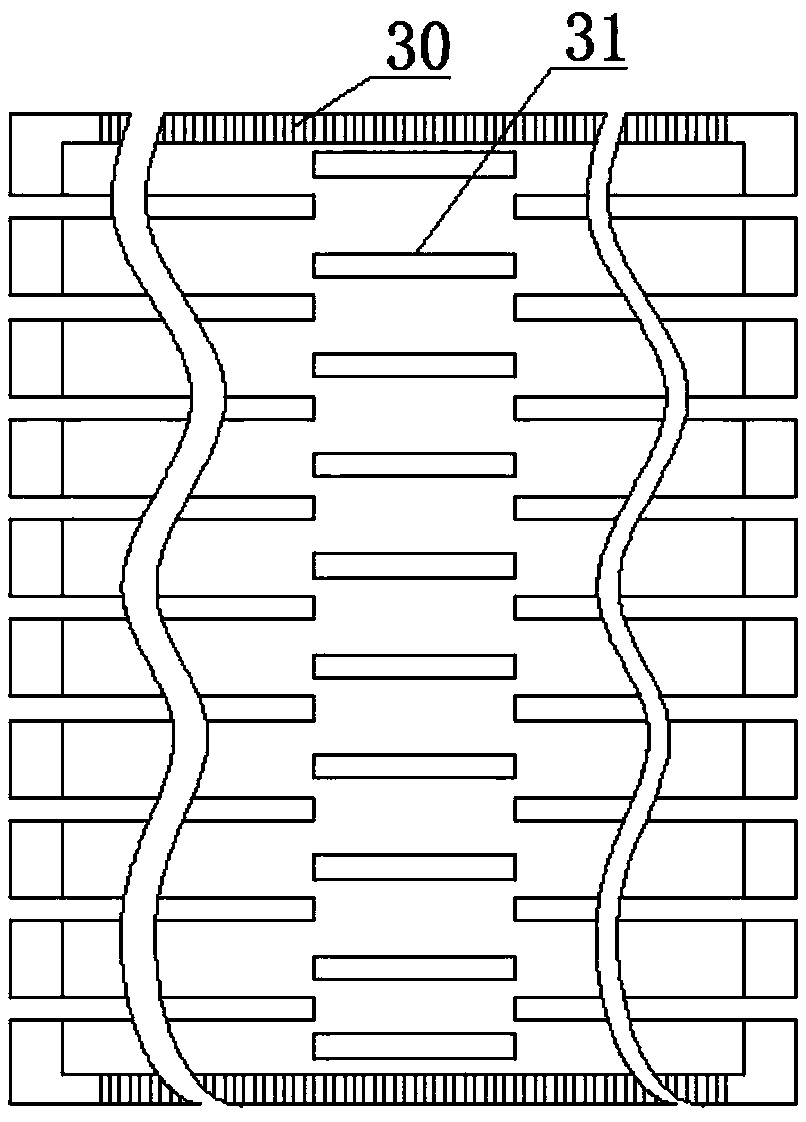

[0019] Example. A texturing and cutting device for the production of monocrystalline silicon wafers, consisting of Figures 1 to 6 As shown, including a frame 1, two electric slide rails 2 arranged symmetrically to each other are arranged on the frame 1, and a plurality of evenly distributed storage frames 3 are arranged between the two electric slide rails 2; One side is provided with mobile platform 4, is connected with the first hydraulic cylinder 5 on mobile platform 4; Shock absorber 6 is installed on the top surface of mobile platform 4, and high speed motor 7 is installed on shock absorber 6; There is a rotating shaft 8, a cleaning liquid inlet pipe 9 is installed on the rotating shaft 8, and a texturing liquid inlet pipe 10 is arranged on one side of the cleaning liquid inlet pipe 9; a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com