High permeability three-layer co-extruded composite film and its application

A three-layer co-extrusion and composite film technology, applied in applications, other household appliances, layered products, etc., can solve the problem of increasing energy consumption and cost of photovoltaic module production, reducing production efficiency and photovoltaic power generation efficiency, and long lamination time, etc. Problems, to achieve the effect of improving production efficiency and photovoltaic power generation efficiency, improving light transmittance and photovoltaic power generation efficiency, and short lamination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

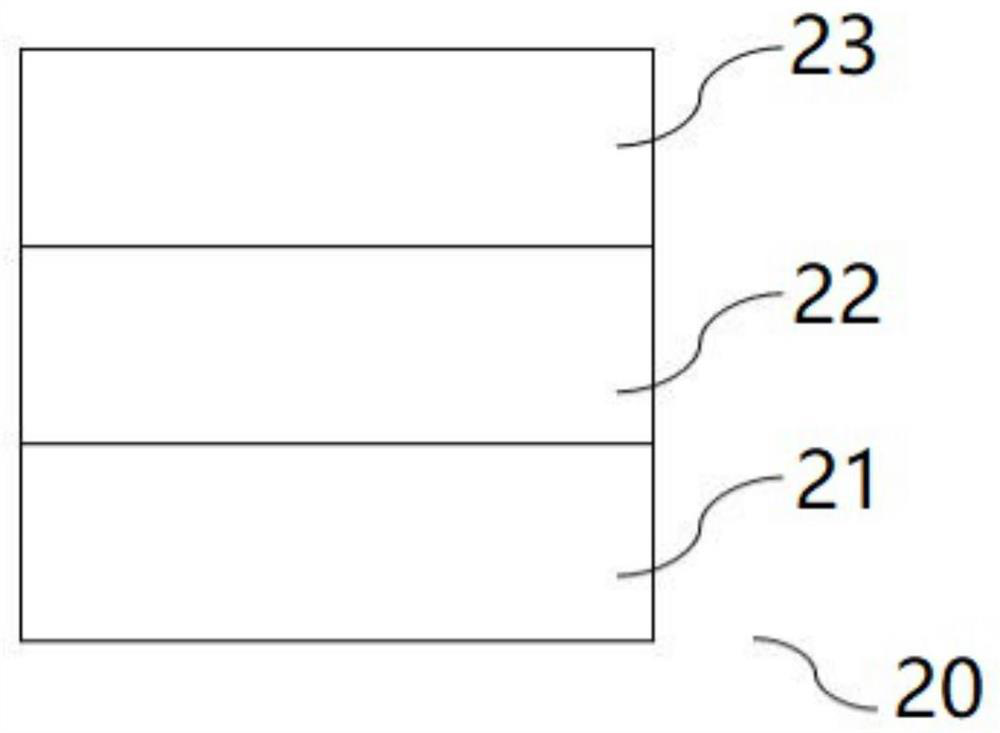

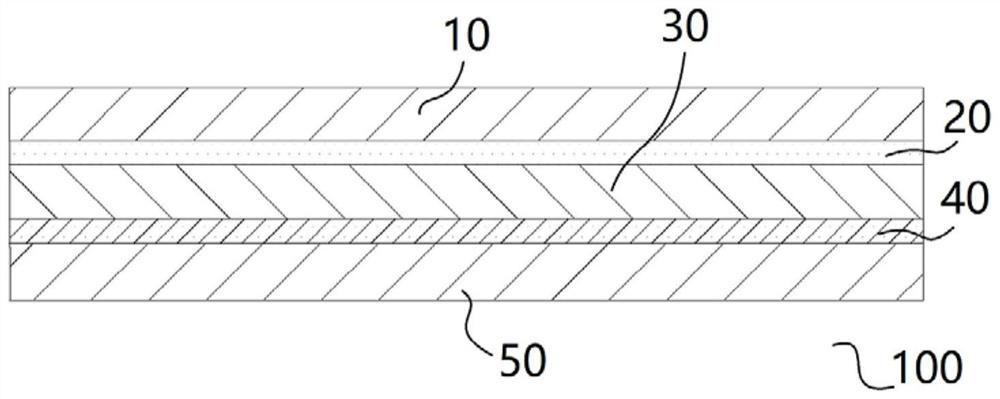

[0045] First, the polyolefin elastomer layer in the middle layer 22 adopts 96.5 kg of polyolefin elastomer particles, 0.2 kg of antioxidant, 1.2 kg of thermal initiator, 1.6 kg of cross-linking monomer, and 0.5 kg of silane coupling agent. The ethylene-vinyl acetate copolymer layer in the inner layer 21 and the outer layer 23 adopts 194.4kg of ethylene-vinyl acetate copolymer rubber particles, 0.4kg of antioxidant, 1.4kg of thermal initiator, and crosslinking monomer 2.0kg, 1.0kg of silane coupling agent, and 0.4kg of light stabilizer were prepared.

[0046] In the preparation process, the ethylene-vinyl acetate copolymer layer and the polyolefin elastomer layer are respectively added to the ethylene-vinyl acetate copolymer layer feeding cylinder and the polyolefin elastomer layer feeding cylinder, and after extrusion at 100 ° C, through the distribution Distributor distribution and co-extrusion die head, obtain three-layer co-extruded composite film, promptly prepare the desi...

Embodiment 2

[0049] First, the polyolefin elastomer layer in the middle layer 22 adopts 96.8 kg of polyolefin elastomer particles, 0.1 kg of antioxidant, 1.1 kg of thermal initiator, 1.5 kg of cross-linking monomer, and 0.4 kg of silane coupling agent. The ethylene-vinyl acetate copolymer layer in the inner layer 21 and the outer layer 23 adopts 195.8kg of ethylene-vinyl acetate copolymer rubber particles, 0.2kg of antioxidant, 1.2kg of thermal initiator, and crosslinking monomer 1.8kg, 0.8kg of silane coupling agent, and 0.2kg of light stabilizer are prepared.

[0050] In the preparation process, the ethylene-vinyl acetate copolymer layer and the polyolefin elastomer layer are respectively added to the ethylene-vinyl acetate copolymer layer feeding cylinder and the polyolefin elastomer layer feeding cylinder, and after extrusion at 100 ° C, through the distribution Distributor distribution and co-extrusion die to obtain a three-layer co-extruded composite film, that is, the desired produc...

Embodiment 3

[0053] First, the polyolefin elastomer layer in the middle layer 22 adopts 95.1 kg of polyolefin elastomer particles, 0.1 kg of antioxidant, 1.0 kg of thermal initiator, 1.0 kg of cross-linking monomer, and 0.3 kg of silane coupling agent. The ethylene-vinyl acetate copolymer layer in the inner layer 21 and the outer layer 23 adopts 196.0kg of ethylene-vinyl acetate copolymer rubber particles, 0.1kg of antioxidant, 1.3kg of thermal initiator, and crosslinking monomer 1.7kg, 0.7kg of silane coupling agent, and 0.3kg of light stabilizer are prepared.

[0054] In the preparation process, the ethylene-vinyl acetate copolymer layer and the polyolefin elastomer layer are respectively added to the ethylene-vinyl acetate copolymer layer feeding cylinder and the polyolefin elastomer layer feeding cylinder, and after extrusion at 100 ° C, through the distribution Distributor distribution and co-extrusion die to obtain a three-layer co-extrusion composite film, that is, the desired produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com