Device and method for achieving safe conveying of catalyst between mutually-exclusive environments

A technology of catalyst and environment, which is applied in the field of safe transportation of catalysts between mutually exclusive environments, can solve the problem of no carrier as gas, avoid transportation difficulties, have broad application prospects, and realize fully automatic detection and step control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

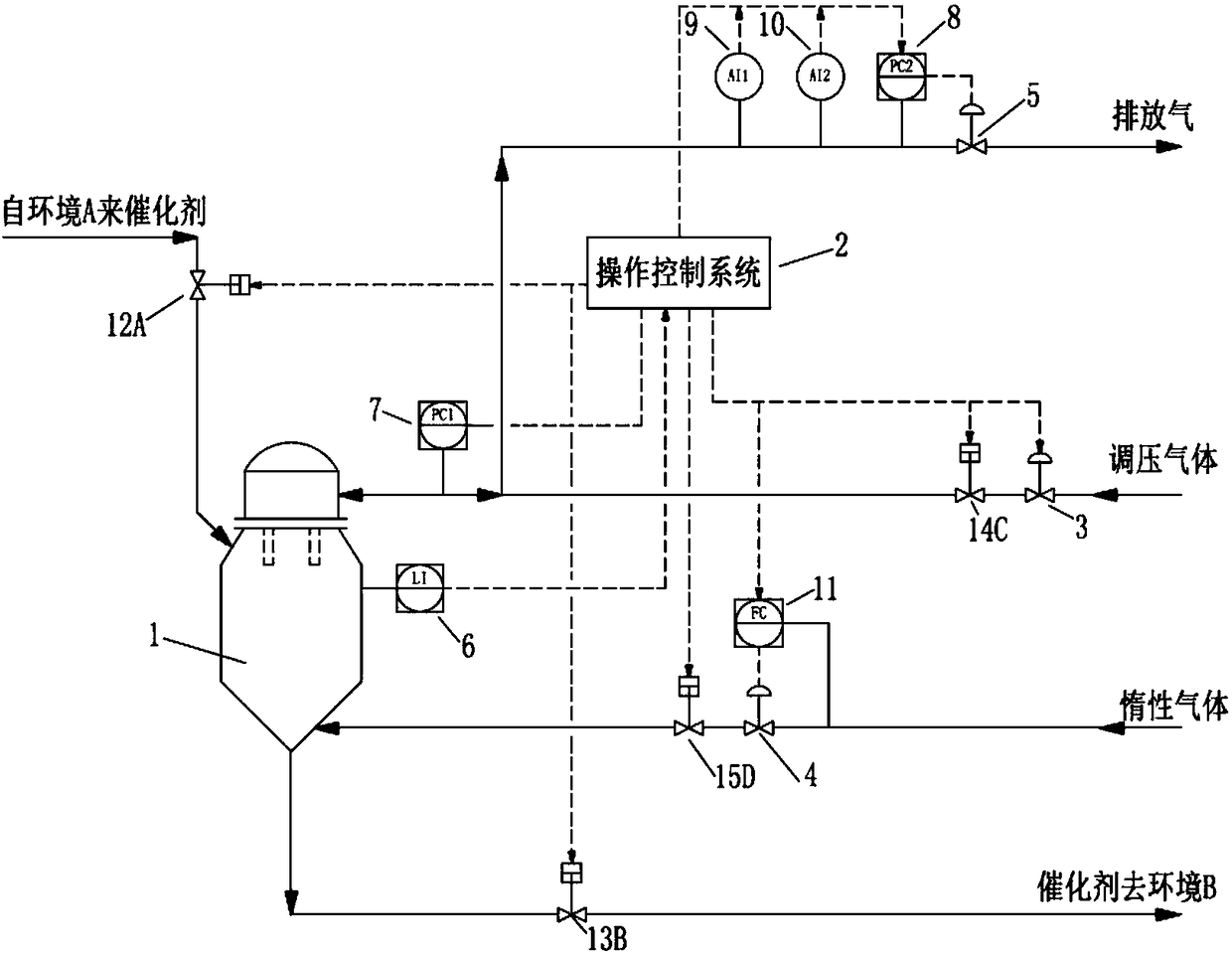

[0044] In one embodiment of the present invention, a method for safely transporting catalysts between hydrogen-oxygen environments is provided, utilizing figure 1 The shown device uses nitrogen as the inert gas and hydrogen as the pressure regulating gas, and the catalyst is transported from the hydrogen environment (environment A) to the oxygen environment (environment B) through five steps, which are:

[0045] Adjust the pressure of hopper 1 slightly lower than the hydrogen environment, fill the hopper 1 from the hydrogen environment, purge the hydrogen in the hopper 1 to a safe concentration with nitrogen, discharge the agent from the hopper 1 to the oxygen environment, and purge the oxygen in the hopper 1 to safe concentration;

[0046] Step 1: Open the pressure-regulating gas regulating valve 3, and the program-controlled on-off valve C 14 presses toward the hopper to keep the pressure of hopper 1 slightly lower than the pressure of the hydrogen environment; the different...

Embodiment 2

[0065] In another embodiment of the present invention, a method for safely transporting catalysts between oxygen-hydrogen environments is provided, utilizing figure 1 The shown device uses nitrogen as the inert gas and pressure regulating gas, and the catalyst is transported from the oxygen environment (environment A) to the hydrogen environment (environment B) through five steps, which are:

[0066] Adjust the pressure of hopper 1 slightly lower than the pressure of the oxygen environment, fill the hopper 1 from the oxygen environment, purge the oxygen in the hopper 1 to a safe concentration with nitrogen, discharge the agent from the hopper 1 to the hydrogen environment, and purge the hydrogen in the hopper 1 with nitrogen to a safe concentration;

[0067] Step 1: Open the pressure-regulating gas regulating valve 3, and the program-controlled switch valve C 14 presses toward the hopper, keeping the pressure of hopper 1 slightly lower than the pressure of the oxygen environme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com