Method for preparing carbon nanotube

A carbon nanotube, electric field direction technology, applied in the direction of carbon nanotubes, single-walled carbon nanotubes, nanostructure manufacturing, etc., can solve problems such as unrealizable and inability to arbitrarily change the chirality of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preparation of the carbon nanotube hand provided by the present invention and the carbon nanotube structure obtained by the method, the thin film transistor prepared by using the carbon nanotube structure, the photodetector, and the photoelectric conversion device will be further detailed in conjunction with specific examples below. illustrate.

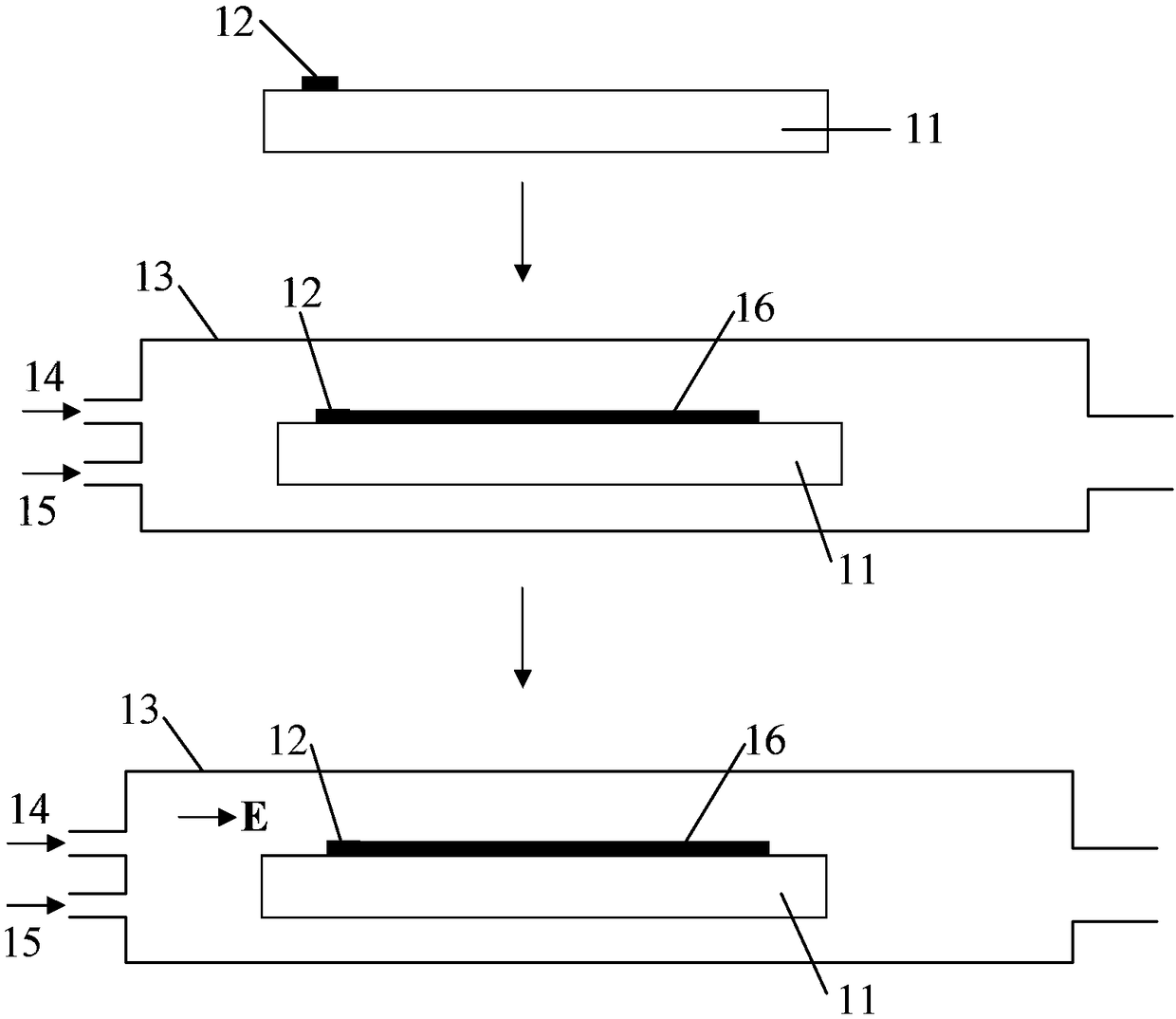

[0031] see figure 1 , the first embodiment of the present invention provides a method for preparing carbon nanotubes, which includes the following steps:

[0032] Step S11, providing a substrate 11, depositing a catalyst layer 12 on the surface of the substrate 11;

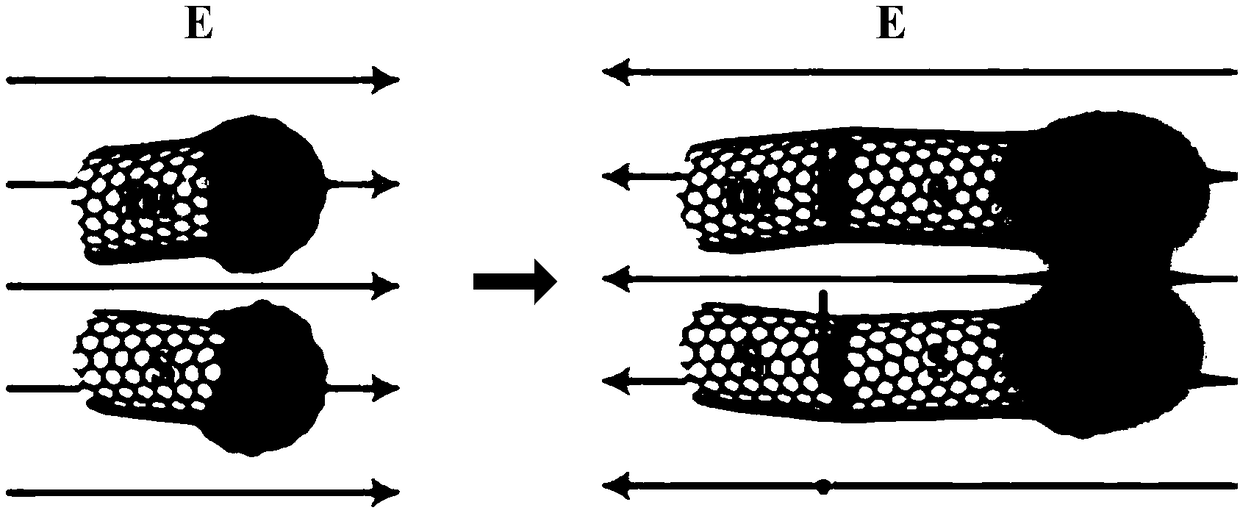

[0033] Step S12, setting the substrate 11 in a reaction furnace 13, heating to make the temperature in the reaction furnace reach a predetermined temperature, passing a carbon source gas 14 and a protective gas 15 into the reaction furnace 13, so that the substrate 11 Growing a carbon nanotube segment structure 16, the carbon nanotube segment structure 16 inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com