Preparation method of pepsin-solubilized collagen from fish scale

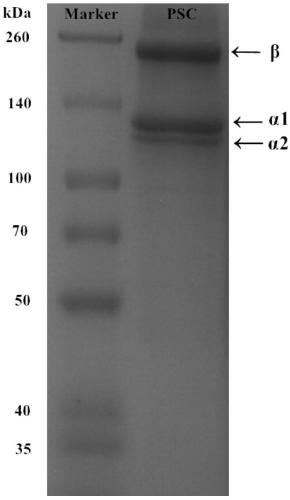

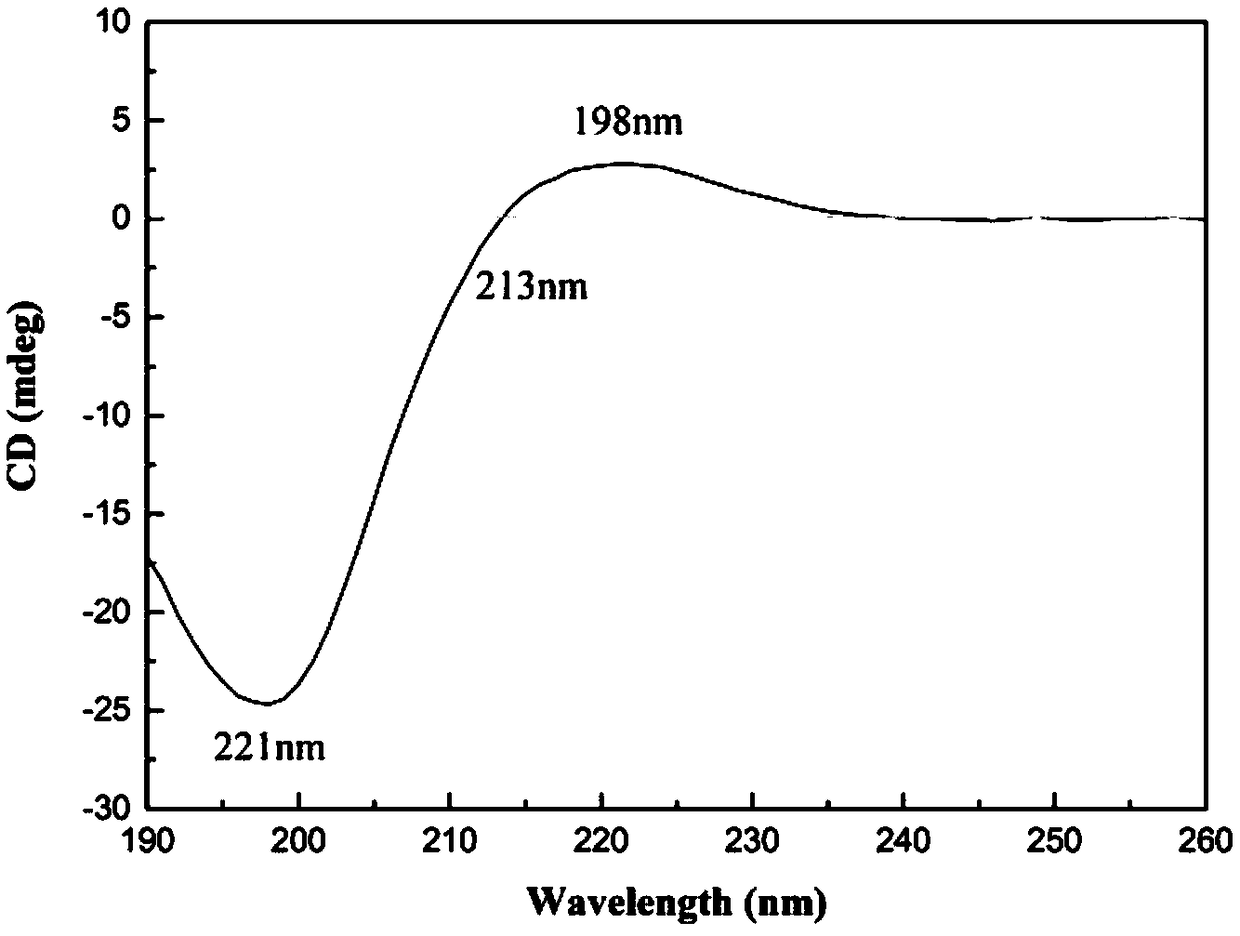

A fish scale and collagen technology, applied in the field of preparation of fish scale enzymatic collagen, can solve the problems of complex process flow, low electrophoresis purity, long separation and purification cycle, etc., and achieves the guarantee of integrity, the preparation process flow is simple, reasonable and easy to operate, and the electrophoresis high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of fish scale enzyme-soluble collagen, comprising the following steps:

[0022] (1) Fish scale pretreatment: remove the impurities in the fish scales, clean the fish scales, and dry them;

[0023] (2) Degreasing and decalcification of fish scales: put 0.5 kg of fish scales in a glass reactor, add 6L of 0.1M NaOH solution (pH=13), stir at 4°C for 24 hours, and change fresh NaOH solution every 12 hours during the stirring process. Then wash to neutral;

[0024] Add 6L 0.5M EDTA-2Na (pH=7.5) to the degreased fish scales for decalcification, stir at 4°C for 36 hours, wash until neutral, and add liquid nitrogen to the pulverizer after drying to crush the fish scales. The mesh size of the punching screen is 10 mesh (aperture is 2.5mm), obtain fish scale powder;

[0025] (3) Extraction of fish scale collagen: add 1L of 0.5M acetic acid solution to 100g of fish scale powder, then add 2g of pepsin, stir at 4°C for 24 hours for enzyme extraction, and then u...

Embodiment 2

[0029] A preparation method of fish scale enzyme-soluble collagen, comprising the following steps:

[0030] (1) Fish scale pretreatment: remove the impurities in the fish scales, clean the fish scales, and dry them;

[0031] (2) Degreasing and decalcification of fish scales: put 2.5kg of fish scales in a glass reactor, add 25L of 0.1M NaOH solution (pH=13), stir at 4°C for 12 hours, and change fresh NaOH solution every 6 hours during the stirring process. Then wash to neutral;

[0032] Add 25L 0.5M EDTA-2Na (pH=7.5) to the degreased fish scales for decalcification, stir at 4°C for 12 hours, wash until neutral, and add liquid nitrogen to the pulverizer after drying to crush the fish scales. The mesh size of the punching screen is 10 mesh (aperture is 2.5mm), obtain fish scale powder;

[0033] (3) Extraction of fish scale collagen: Add 2L of 0.5M acetic acid solution to 200g of fish scale powder, then add 3g of pepsin, stir at 4°C for 36h for enzyme extraction, and then use a ...

Embodiment 3

[0037] A preparation method of fish scale enzyme-soluble collagen, comprising the following steps:

[0038] (1) Fish scale pretreatment: remove the impurities in the fish scales, clean the fish scales, and dry them;

[0039] (2) Degreasing and decalcifying fish scales: put 5 kg of fish scales in a glass reactor, add 40L 0.1M NaOH solution (pH=13), stir at 4°C for 12 hours, change the fresh NaOH solution every 6 hours during the stirring process, and then Wash to neutral;

[0040] Add 40L 0.5M EDTA-2Na (pH=7.5) to the degreased fish scales for decalcification, stir at 4°C for 24 hours, wash until neutral, and add liquid nitrogen to the pulverizer after drying to crush the fish scales. The mesh size of the punching screen is 10 mesh (aperture is 2.5mm), obtain fish scale powder;

[0041] (3) Extraction of fish scale collagen: add 3L 0.5M acetic acid solution to 300g fish scale powder, then add 3g pepsin, stir at 4°C for 48h for enzyme extraction, and then use a large high-spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com