Polyolefin VOC adsorption masterbatch and preparation method thereof

A technology of polyolefin and masterbatch, which is applied in the field of polyolefin VOC adsorption masterbatch and its preparation, achieving good promotion value, low price and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

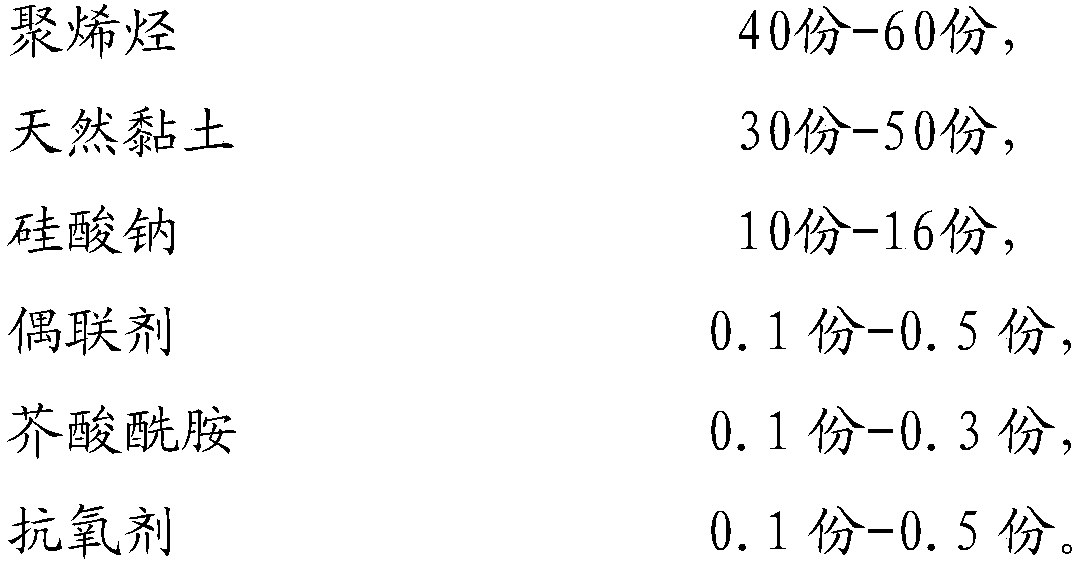

[0026] The preparation method of any one of the above-mentioned polyolefin VOC adsorption masterbatches comprises the following steps:

[0027] (1) Weigh 40-60 parts of polyolefin, 30-50 parts of natural clay, 10-16 parts of sodium silicate, 0.1-0.5 parts of coupling agent, 0.1-0.3 parts of erucamide, 0.1 Part-0.5 part of antioxidant is mixed and stirred evenly to obtain a mixture;

[0028] (2) Extrude the mixture obtained in step (1) from an extruder to obtain VOC adsorption masterbatches.

Embodiment 1

[0030] (1) Weigh 40 parts of PP, 30 parts of natural clay, 10 parts of sodium silicate, 0.1 part of coupling agent AC-201, 0.1 part of erucamide, 0.1 part of Irganox168, mix and stir evenly to obtain a mixture;

[0031] (2) extrude the mixture obtained in step (1) from the extruder to obtain VOC adsorption masterbatch P1.

[0032] Among them, the twin-screw extruder includes six temperature zones arranged in sequence, the temperature of the first zone is 170°C, the temperature of the second zone is 230°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 230°C, and the temperature of the fifth zone is 230°C, the temperature in the sixth zone is 230°C, the head temperature is 230°C, and the screw speed is 220r / min.

Embodiment 2

[0043] (1) Weigh 60 parts of PBT, 50 parts of natural clay, 16 parts of sodium silicate, 0.5 part of coupling agent AC-201, 0.3 part of erucamide, 0.1 part of Irganox168, 0.2 part of Irganox1010, 0.2 part of Irganox1330, mix and stir evenly , to get the mixture;

[0044] (2) Extrude the mixture obtained in step (1) from the extruder to obtain VOC adsorption masterbatch P2.

[0045] Among them, the twin-screw extruder includes six temperature zones arranged in sequence, the temperature of the first zone is 200°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, and the temperature of the fifth zone is 260°C, the temperature in the sixth zone is 260°C, the head temperature is 260°C, and the screw speed is 300r / min.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap