Preparation method of polyolefin VOC (Volatile Organic Compound) improved filler and composite material containing polyolefin VOC improved filler

A technology of polyolefin and composite sol, which is applied in fibrous fillers, chemical instruments and methods, inorganic pigment treatment, etc., can solve the problems of poor physical properties and achieve the effect of improving VOC performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

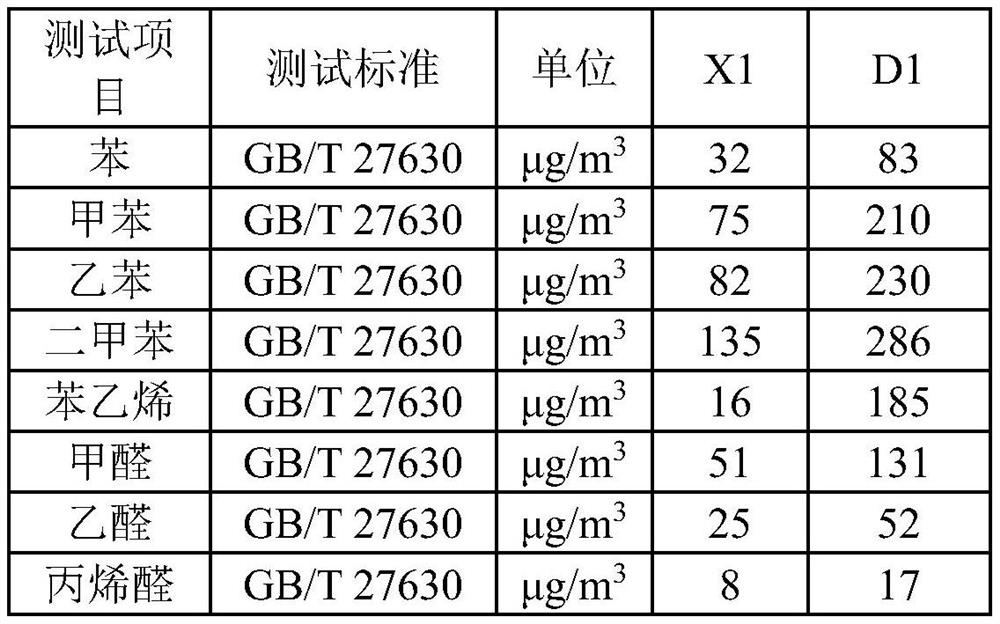

Embodiment 1

[0032] A preparation method of polyolefin VOC improved filler, comprising the following steps:

[0033] (1) Weigh 100g of acetic acid, 600g of acetone, and 300g of tetraethyl orthosilicate, add them to the reaction vessel, and stir and react for 4h at room temperature to obtain SiO 2 sol.

[0034] (2) Weigh 200g of sodium molybdate, 180g of hydrochloric acid and 600g of deionized water, add them into the reaction vessel, and stir and react at room temperature for 6h to obtain MoO 3 sol.

[0035] (3) Weigh 200g SiO 2 Sol, 240gMoO 3 The sol was added to a reaction vessel, and the reaction was stirred at room temperature for 1 h to obtain a SiO2-MoO3 composite sol.

[0036] (4) Weigh 200g of hydrotalcite, 300g of SiO 2 -MoO 3 The composite sol and 700 g of acetone were added to the reaction vessel, stirred and reacted at room temperature for 6 h, filtered, washed and dried to obtain hydrotalcite-supported SiO 2 -MoO 3 Type VOC-improving filler P1.

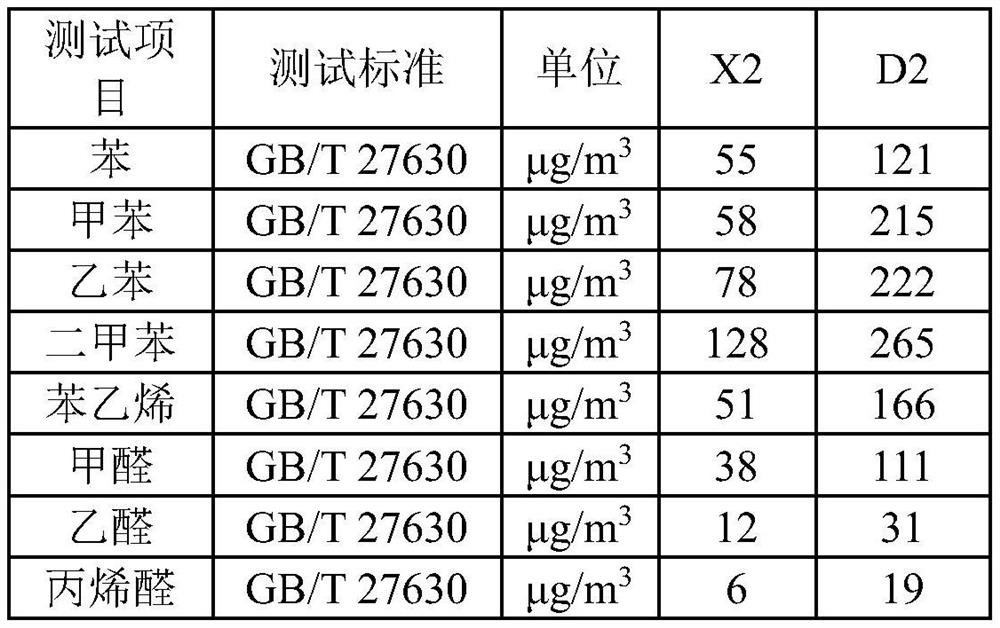

Embodiment 2

[0047] A preparation method of polyolefin VOC improved filler, comprising the following steps:

[0048] (1) Weigh 160g of acetic acid, 800g of acetone, and 400g of tetraethyl orthosilicate, add them to the reaction vessel, and stir and react at room temperature for 6h to obtain SiO 2 sol.

[0049] (2) Weigh 240g of sodium molybdate, 240g of hydrochloric acid, 800g of deionized water, add them into the reaction vessel, and stir and react at room temperature for 8h to obtain MoO 3 sol.

[0050] (3) Weigh 300g SiO 2 Sol, 280gMoO 3 The sol was added to the reaction vessel, and the reaction was stirred at room temperature for 3 hours to obtain SiO 2 -MoO 3 composite sol.

[0051] (4) Weigh 300g of hydrotalcite, 400g of SiO 2 -MoO 3The composite sol and 800 g of acetone were added to the reaction vessel, stirred and reacted at room temperature for 8 hours, filtered, washed and dried to obtain a hydrotalcite-supported SiO2-MoO3 type VOC improved filler P2.

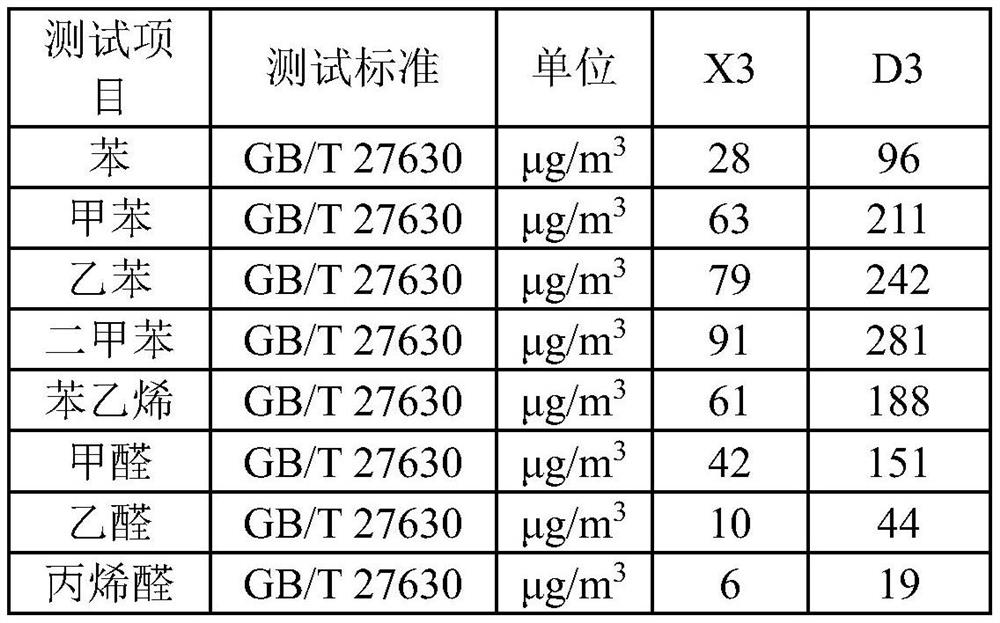

Embodiment 3

[0062] A preparation method of polyolefin VOC improved filler, comprising the following steps:

[0063] (1) Weigh 130g of acetic acid, 700g of acetone, and 350g of tetraethyl orthosilicate, add them to the reaction vessel, and stir and react for 5h at room temperature to obtain SiO 2 sol.

[0064] (2) Weigh 220g of sodium molybdate, 210g of hydrochloric acid, 700g of deionized water, add them into the reaction vessel, and stir and react at room temperature for 7h to obtain MoO 3 sol.

[0065] (3) Weigh 250g SiO 2 Sol, 260gMoO 3 The sol was added to the reaction vessel, and the reaction was stirred at room temperature for 2 h to obtain SiO 2 -MoO 3 composite sol.

[0066] (4) Weigh 250g of hydrotalcite, 350g of SiO 2 -MoO 3 The composite sol and 750 g of acetone were added to the reaction vessel, stirred and reacted at room temperature for 7 h, filtered, washed and dried to obtain the hydrotalcite-supported SiO 2 -MoO 3 Type VOC-improving filler P3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap