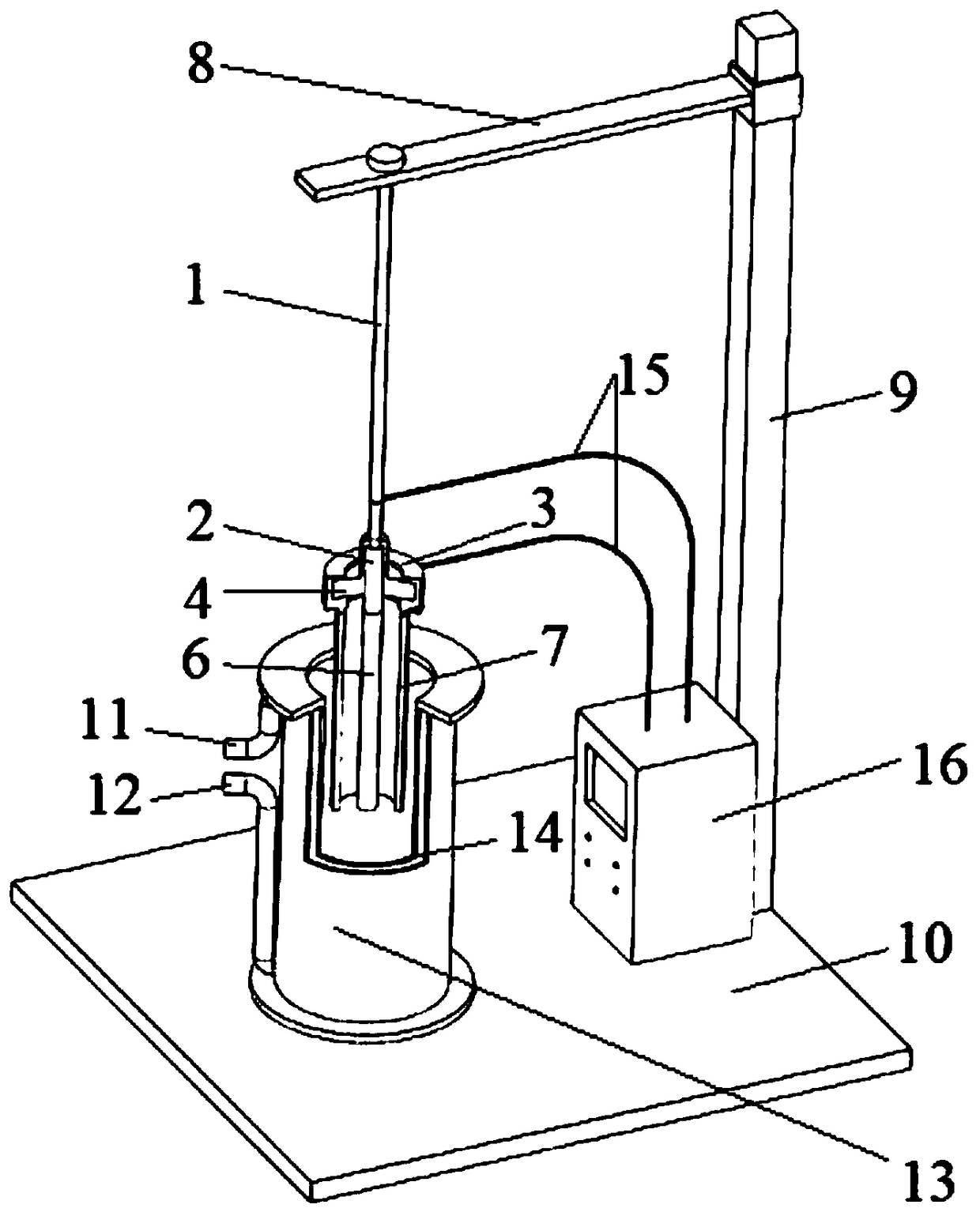

Interior-rodlike and exterior-tubular type electroslag remelting device with double electrodes connected in series and method

An electroslag remelting and tubular technology, applied in the field of metal smelting, can solve the problems of slow melting speed at the center of the end of the columnar self-consumable electrode, increased content of inclusions in large steel ingots, and poor refining effect of metal droplets, etc., to achieve The effect of overcoming adverse effects, reducing inclusion content, and reducing magnetic steel structural parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

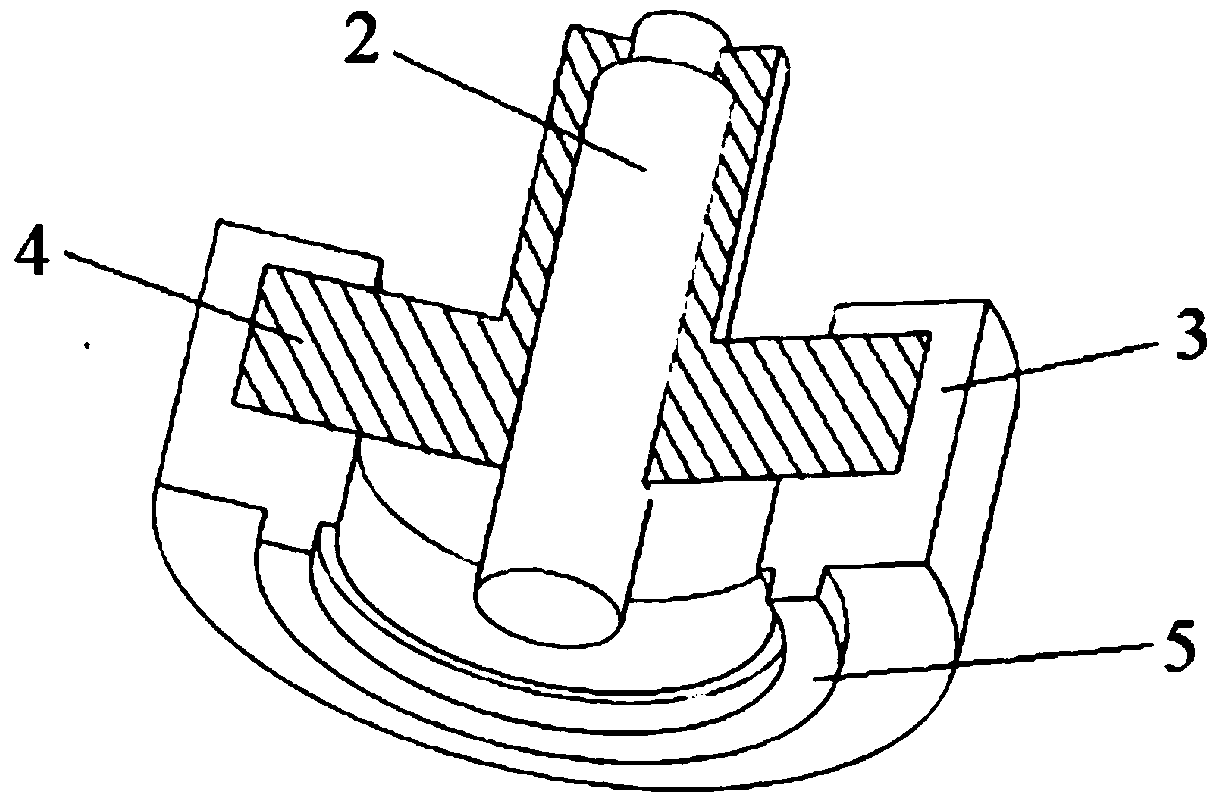

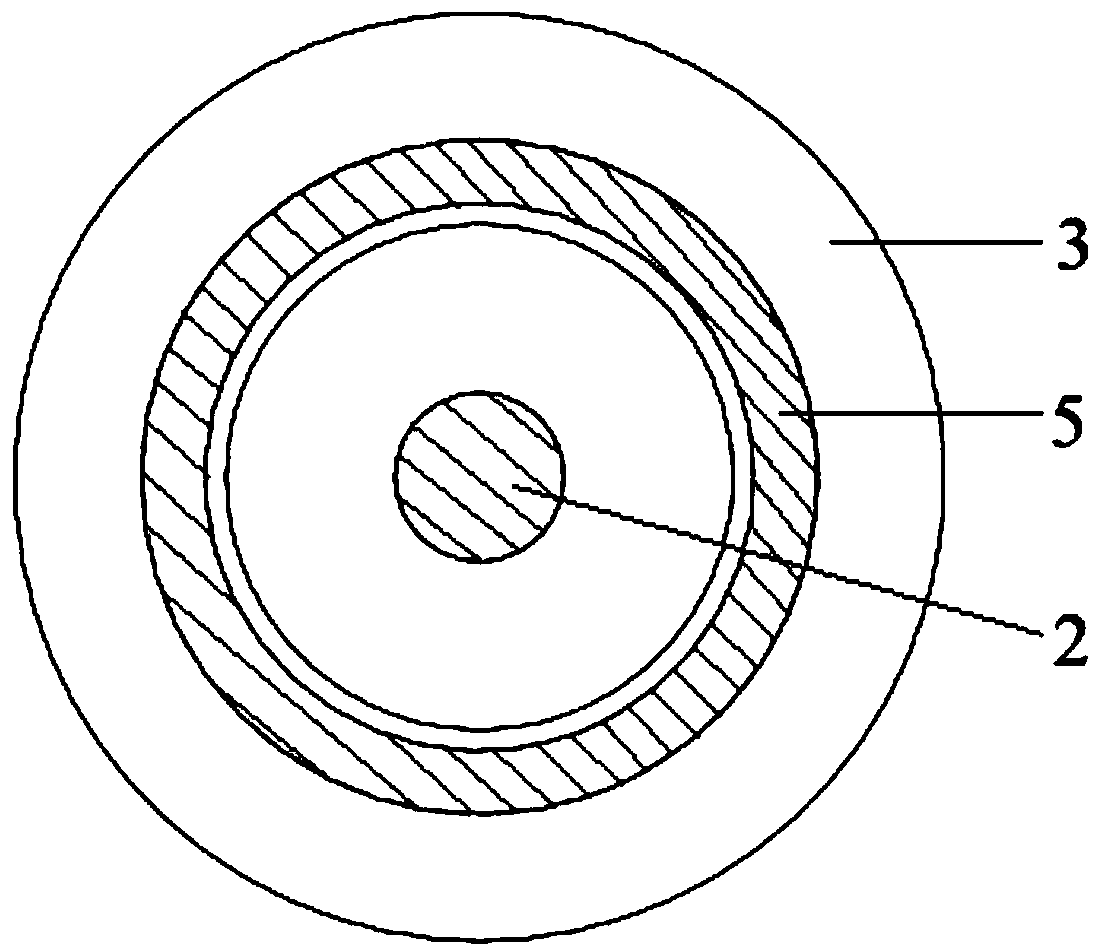

[0077] Embodiment 2 proposes another inner rod and outer tube type bipolar series electroslag remelting device, which is basically the same as Embodiment 1, except that: Figure 5 , 8 As shown, the outer tubular consumable electrode 7 is set as an electrode group consisting of a plurality of small-diameter rod-shaped consumable electrodes distributed evenly in the ring at the bottom of the consumable electrode connection disc outer ring 3, and the electrode groups are arranged in a tubular shape Surrounding the inner rod-shaped consumable electrode 6. Wherein, the cross-sectional area of the electrode group is equal to the cross-sectional area of the inner rod-shaped consumable electrode 6 . The number of electrode groups is generally determined according to the quality of the steel ingot to be smelted. If the quality of the steel ingot is large, 8 electrodes can be installed, and if the quality of the steel ingot is small, 6 electrodes can be installed. Then, according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com