Environment-friendly low-radiation glass and preparation method thereof

A low-emissivity glass, environmental protection technology, applied in the direction of sputtering plating, ion implantation plating, coating, etc., can solve the problems of light pollution, poor appearance, glass transmittance reduction, etc., to achieve high and low radiation performance, excellent performance, high Effect of Visible Light Transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

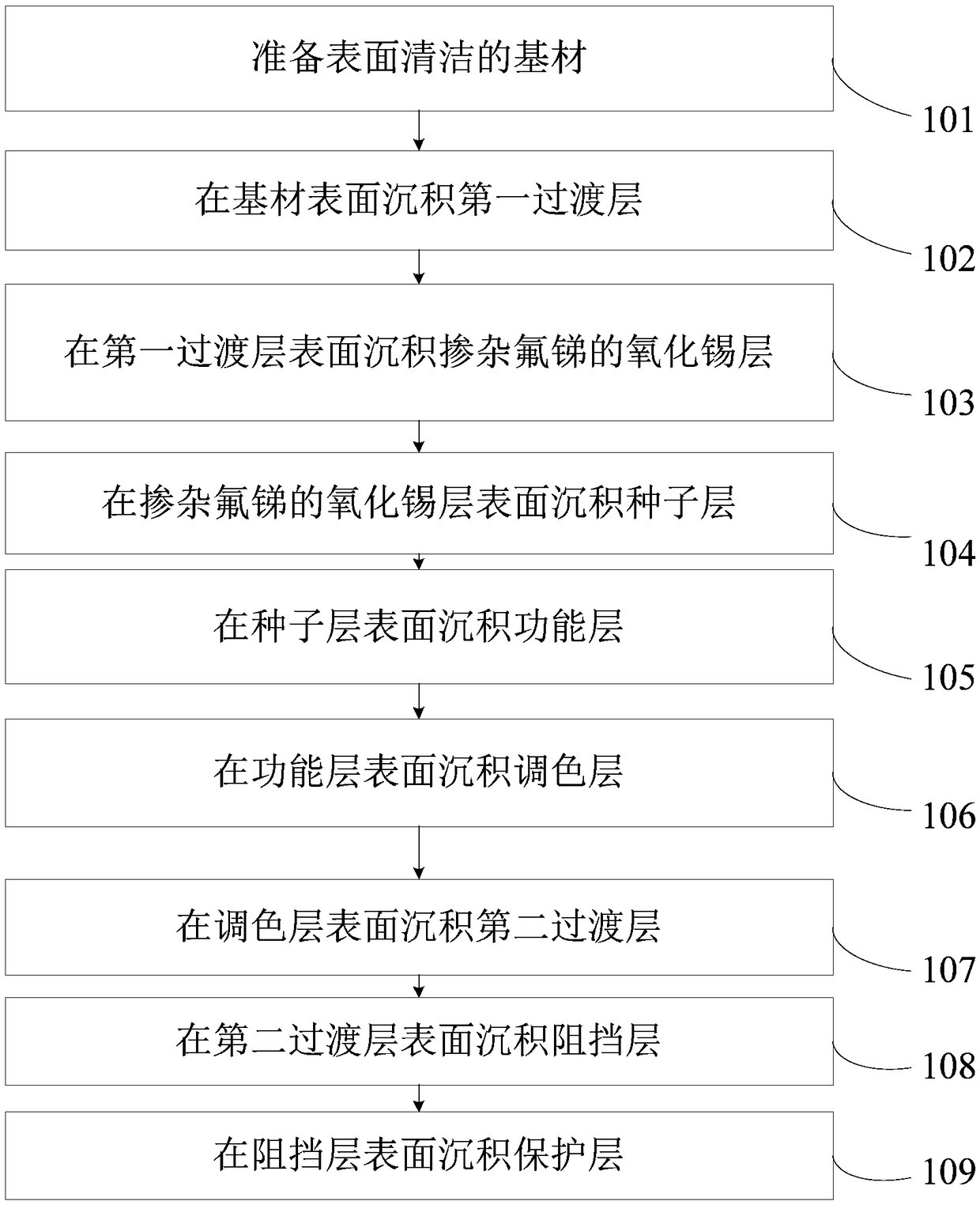

[0021] As shown in Figure 1, the preparation method of the environmentally friendly low-emissivity glass of the present invention includes the following steps: Step 101: prepare a substrate with a clean surface; step 102: deposit the first transition layer on the substrate surface; step 103: in the first transition Depositing a tin oxide layer doped with fluorine antimony on the surface of the layer; step 104: depositing a seed layer on the surface of the tin oxide layer doped with fluorine antimony; step 105: depositing a functional layer on the surface of the seed layer; step 106: depositing a color tone on the surface of the functional layer layer; step 107: depositing a second transition layer on the surface of the toning layer; step 108: depositing a blocking layer on the surface of the second transition layer; and step 109: depositing a protective layer on the surface of the blocking layer.

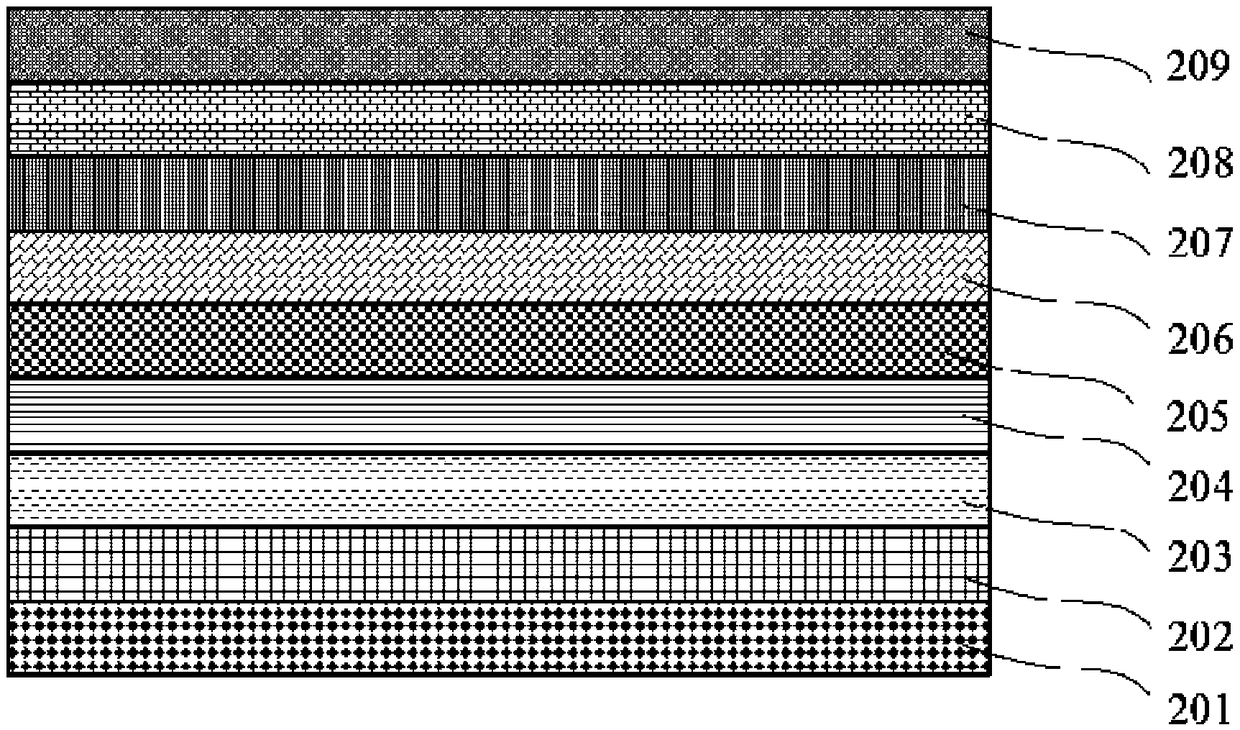

[0022] Such as figure 2 As shown, the environmental-friendly low-emissivity gl...

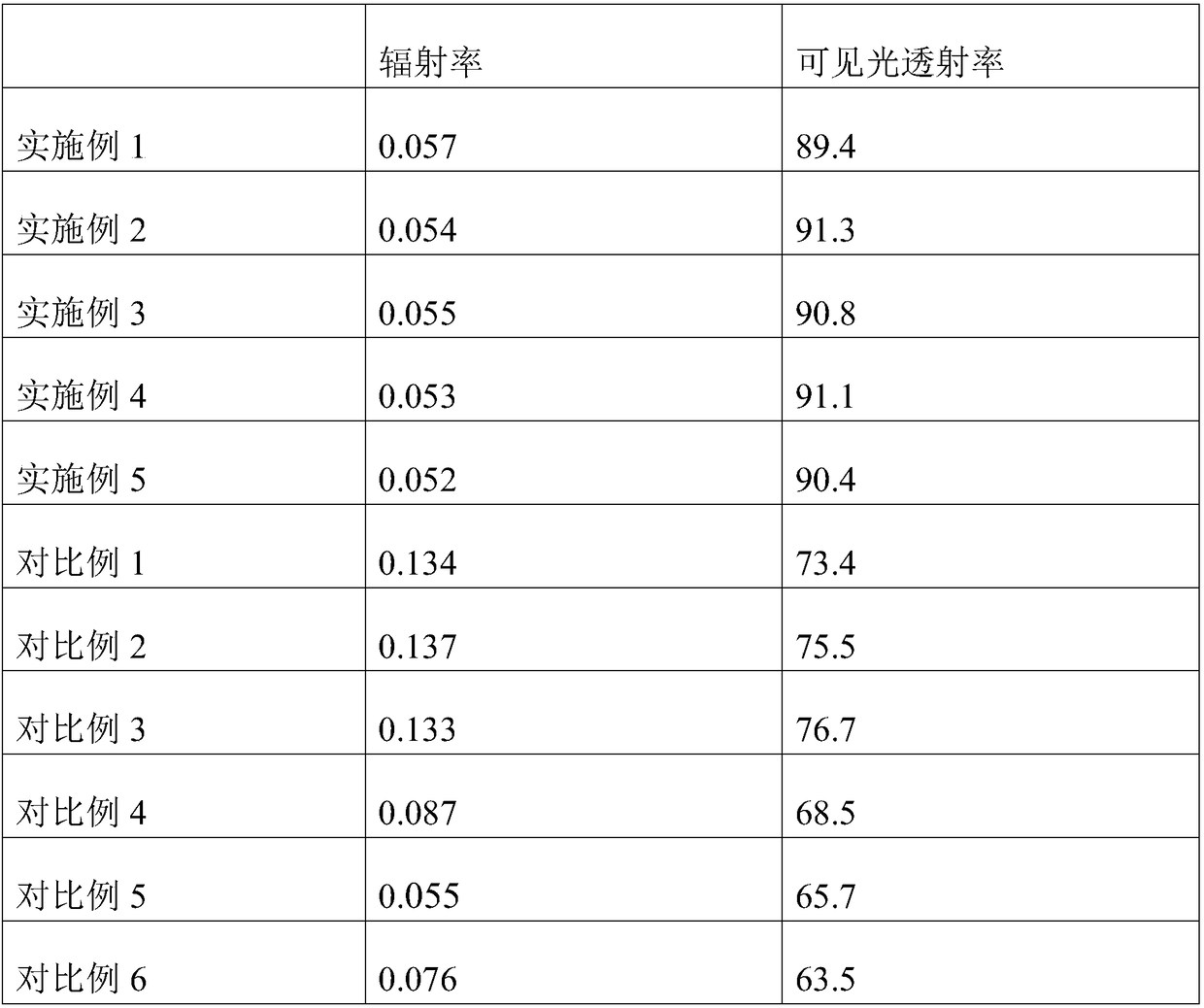

Embodiment 1

[0025]The preparation method of the environment-friendly low-emissivity glass comprises the following steps: preparing a substrate with a clean surface; depositing a first transition layer on the surface of the substrate; depositing a tin oxide layer doped with fluorine and antimony on the surface of the first transition layer; A seed layer is deposited on the surface of the tin oxide layer; a functional layer is deposited on the surface of the seed layer; a toning layer is deposited on the surface of the functional layer; a second transition layer is deposited on the surface of the toning layer; a barrier layer is deposited on the surface of the second transition layer; Deposition protective layer; Wherein, seed layer is metal Cu layer, and the thickness of seed layer is 10nm, and functional layer is metal Ag layer, and the thickness of functional layer is 5nm, and the color-toning layer is metal Pd layer, and the thickness of color-coloring layer is 8nm, The second transition...

Embodiment 2

[0027] The preparation method of the environment-friendly low-emissivity glass comprises the following steps: preparing a substrate with a clean surface; depositing a first transition layer on the surface of the substrate; depositing a tin oxide layer doped with fluorine and antimony on the surface of the first transition layer; A seed layer is deposited on the surface of the tin oxide layer; a functional layer is deposited on the surface of the seed layer; a toning layer is deposited on the surface of the functional layer; a second transition layer is deposited on the surface of the toning layer; a barrier layer is deposited on the surface of the second transition layer; Deposition protection layer; Wherein, seed layer is metal Cu layer, and the thickness of seed layer is 5nm, and functional layer is metal Ag layer, and the thickness of functional layer is 10nm, and the color-coloring layer is metal Pd layer, and the thickness of color-coloring layer is 3nm, The second transit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com