Antibacterial nanofiber and preparation method thereof

A nanofiber and cellulose technology, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of bacterial growth and poor antibacterial ability, and achieve the effect of simple operation, elimination of poor antibacterial ability, and reasonable preparation process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

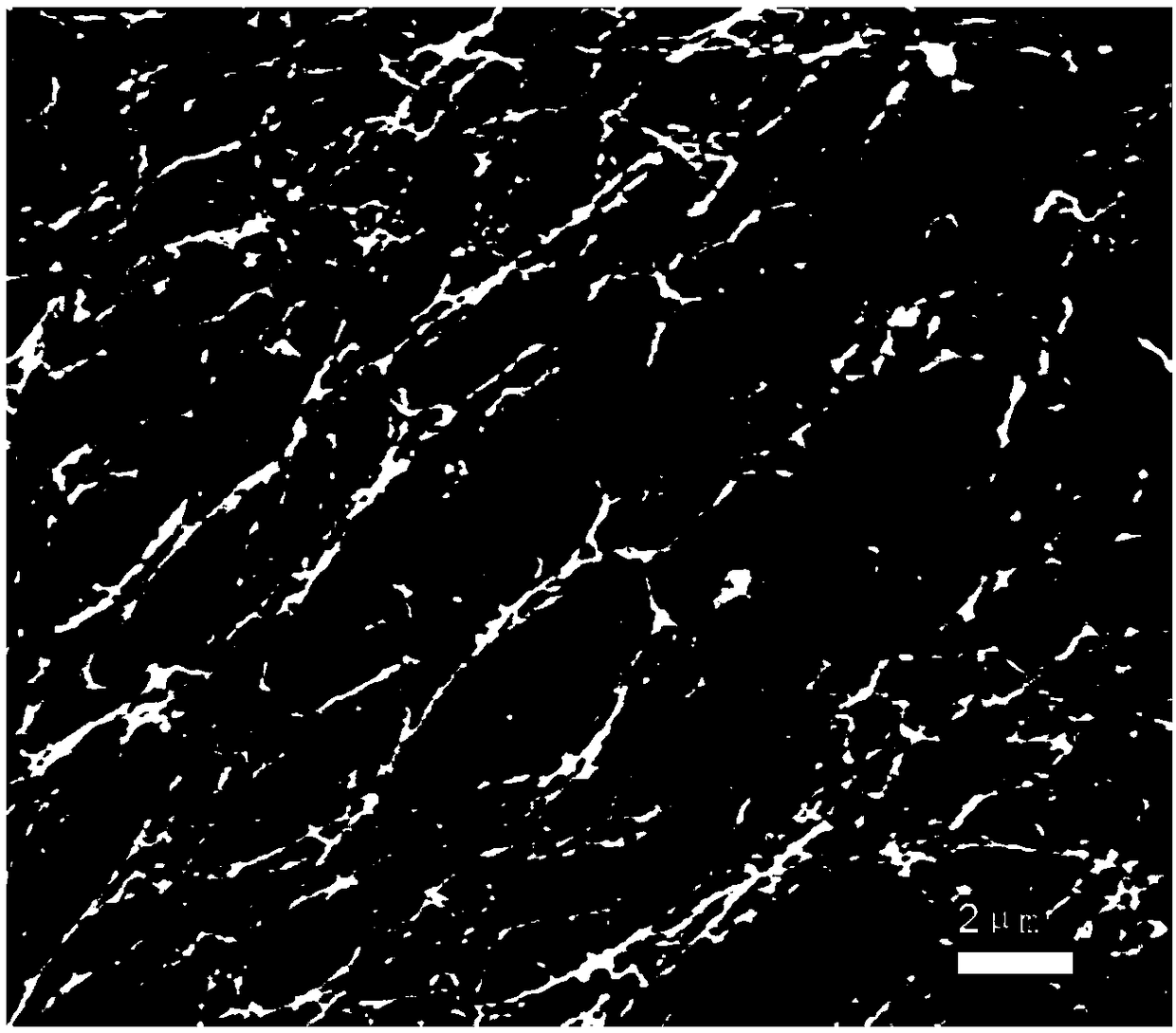

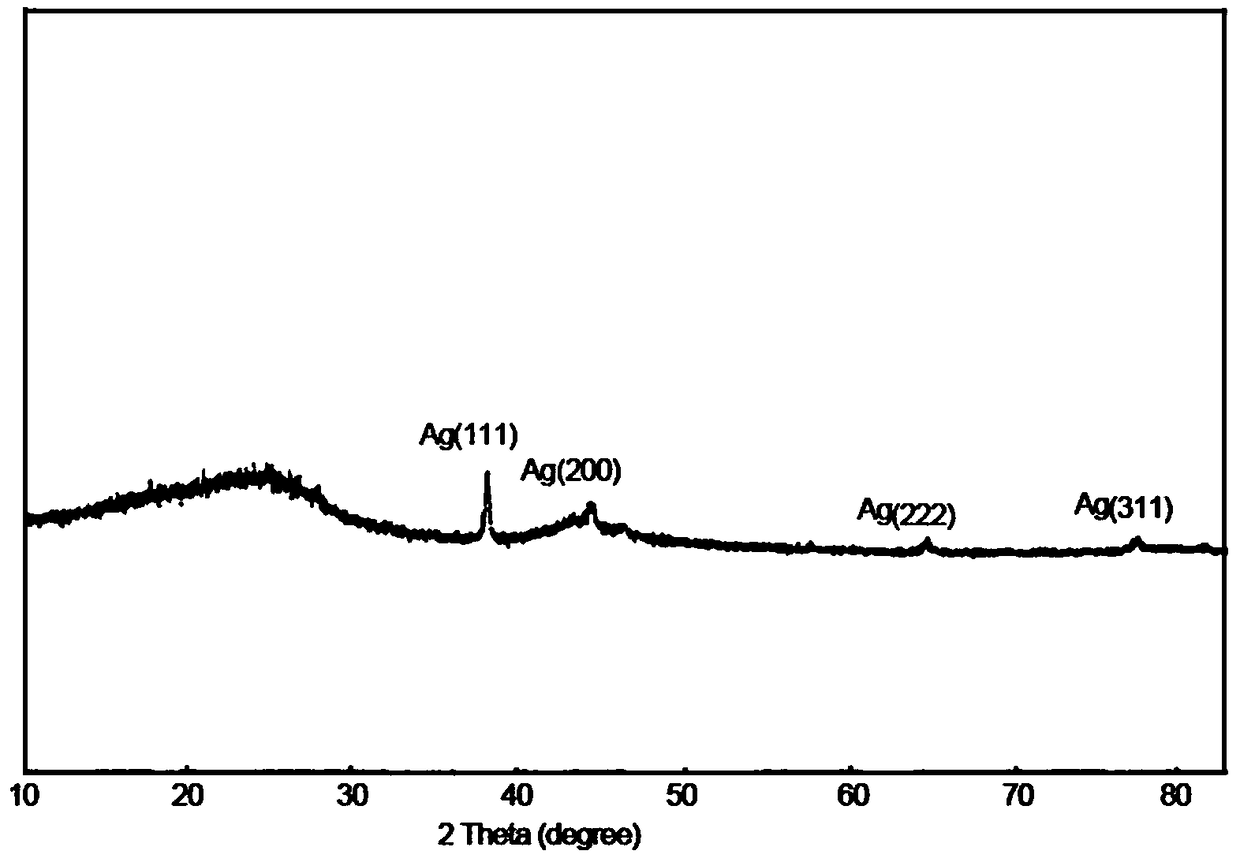

[0027] An antibacterial nanofiber and a preparation method thereof. Firstly, the biomass lignocellulosic material is prepared by physical and chemical treatment methods to prepare cellulose nanofibers, and then the cellulose nanofibers are placed in an oxidizing agent solution for oxidation treatment to obtain oxidized nanofibers, and then Place the oxidized nanofibers in silver ammonia solution for ion exchange and dry to obtain antibacterial nanofibers;

[0028] A kind of preparation method of antibacterial nanofiber comprises the following steps:

[0029] Step 1: First, the biomass lignocellulosic material is pulverized by a pulverizer, and then passed through an 80-mesh sieve to obtain fiber powder;

[0030] Step 2: Use the chemical extraction method to process the powder obtained in Step 1, and then carry out alkali treatment under stirring conditions. The alkali treatment temperature is 65 ° C, and the reaction time is 2.5 hours; after the reaction is completed, filter a...

Embodiment 2

[0037] An antibacterial nanofiber and a preparation method thereof. Firstly, the biomass lignocellulosic material is prepared by physical and chemical treatment methods to prepare cellulose nanofibers, and then the cellulose nanofibers are placed in an oxidizing agent solution for oxidation treatment to obtain oxidized nanofibers, and then Place the oxidized nanofibers in silver ammonia solution for ion exchange and dry to obtain antibacterial nanofibers;

[0038] A kind of preparation method of antibacterial nanofiber comprises the following steps:

[0039] Step 1: First, the biomass lignocellulosic material is pulverized by a pulverizer, and then passed through a 80-100 mesh sieve to obtain a fiber powder;

[0040] Step 2: Use the method of chemical extraction to process the powder obtained in Step 1, and then carry out alkali treatment under stirring conditions. The temperature of alkali treatment is 90°C, and the reaction time is 1.5h; after the reaction is completed, filt...

Embodiment 3

[0047] An antibacterial nanofiber and a preparation method thereof. Firstly, the biomass lignocellulosic material is prepared by physical and chemical treatment methods to prepare cellulose nanofibers, and then the cellulose nanofibers are placed in an oxidizing agent solution for oxidation treatment to obtain oxidized nanofibers, and then Place the oxidized nanofibers in silver ammonia solution for ion exchange and dry to obtain antibacterial nanofibers;

[0048] A kind of preparation method of antibacterial nanofiber comprises the following steps:

[0049] Step 1: First, the biomass lignocellulosic material is pulverized by a pulverizer, and then passed through a 80-100 mesh sieve to obtain a fiber powder;

[0050] Step 2, use the chemical extraction method to process the powder obtained in step 1, and then carry out alkali treatment under stirring conditions, the alkali treatment temperature is 80 ° C, and the reaction time is 2 hours; after the reaction is completed, filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com