Patents

Literature

62results about How to "Reasonable design of preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-retardant ACS/PVC plastic alloy and manufacturing method thereof

ActiveCN101591463AImprove flame retardant performanceGood weather resistanceProcedure AgentsEngineering plastic

The invention relates to a fire-retardant ACS / PVC plastic alloy and a manufacturing method thereof. The alloy uses ACS resin and PVC resin as base materials; and compound fire retardant, stabilizer, compatilizer, processing aid, antioxidant and lubricant are added into the base materials in proportion by weight, then the materials are mixed at high speed, and the mixture is blended, extruded and granulated in a double-screw extruder to form the alloy. The prepared fire-retardant ACS / PVC plastic alloy has the advantages of good fire-retardant property, weather resisting property, electrostatic resistance, mechanical property and processing property, can be widely applied in the fields of electron, electrical appliances, communication, instruments, building materials, automobile parts and the like, and is an engineering plastic alloy with good development prospect.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

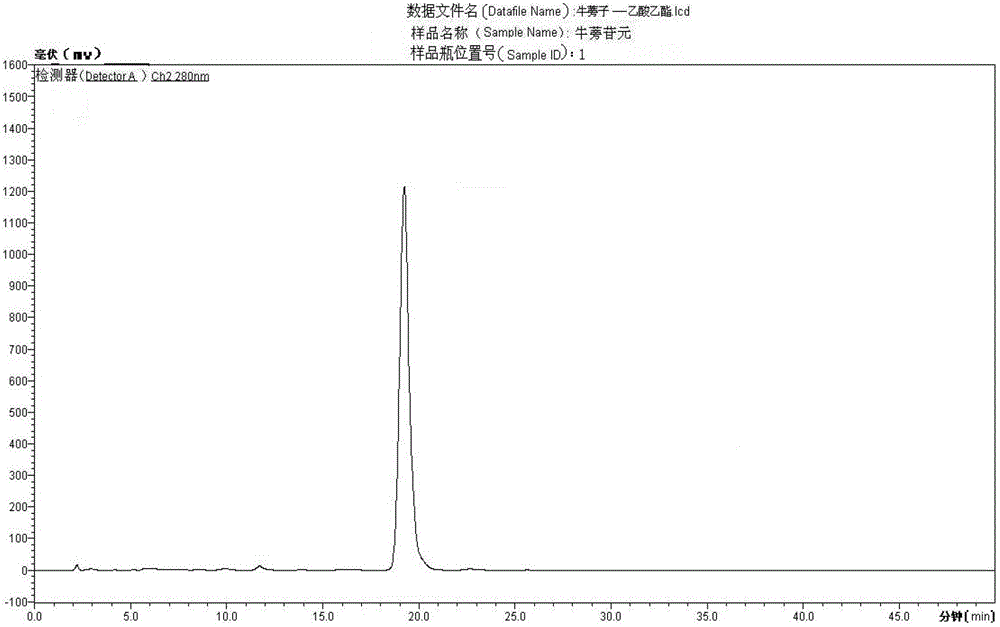

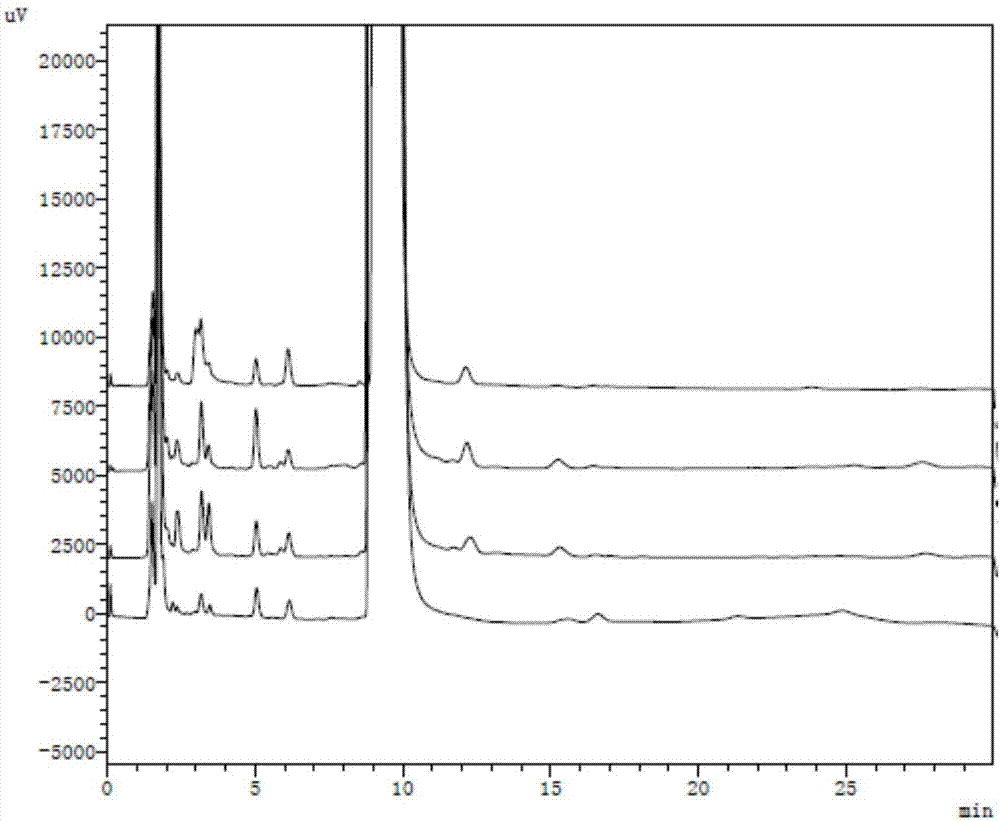

Preparation method of high-purity arctigenin

InactiveCN103145655AAvoid thermal changesAvoid interferenceOrganic chemistryFluid phaseEthyl acetate

The invention discloses a preparation method of high-purity arctigenin. The preparation method of the high-purity arctigenin does not need a heating return flow method to extract arctigenin constituents, does not need an enzymolysis method and a column chromatography, and directly uses ethyl acetate diacolation to extract arctiin in burdock, the potential of hydrogen (PH) value of a diacolation concentrated solution is adjusted to be 3.0-4.0, the arctiin is directly hydrolyzed to become an arctigenin crude product, and an opposite phase preparative liquid chromatography optimized by a large number of experiments is adopted to obtain the high-purity arctigenin. The preparation method of the high-purity arctigenin is reasonable and in the entire preparation process design, high in preparation efficiency, strong in operability, and suitable for industrialized mass production.

Owner:NANJING HAIYUAN CHINESE HERBAL PIECES CO LTD

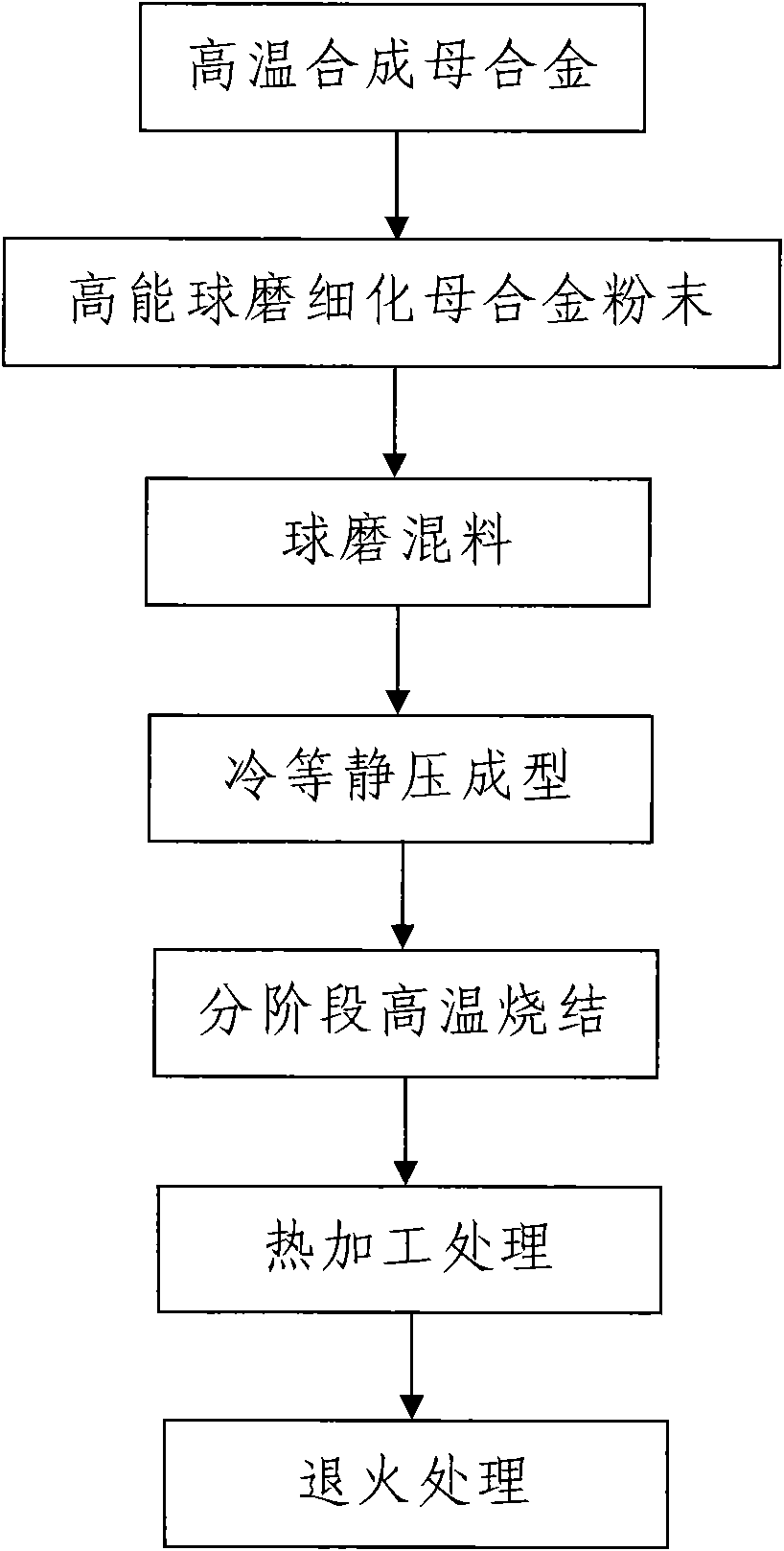

Method for preparing superhigh temperature resistant iridium alloy by using powder metallurgy method

InactiveCN101831568AReasonable design of preparation processThe method steps are simpleCrystallitePowder metallurgy

The invention discloses a method for preparing a superhigh temperature resistant iridium alloy by using a powder metallurgy method, comprising the following steps of: 1, synthesizing a mother alloy at high temperature; 2. Ball-milling and refining mother alloy powder at high energy; 3, ball-milling mixed material: adding a proper amount of iridium powder in the mother alloy powder to form a mixed powder and sufficiently mixing the mixed powder by using a ball mill; 4, cold isostatic pressing forming: filling the mixed powder into a cold isostatic pressing mold for cold isostatic pressing to prepare a powder pressed shape; 5, high-temperature sintering treatment: sintering the powder pressed shape in stage at high temperature; 6, hot processing treatment: forging and / or rolling the sintered powder pressed shape at high temperature by adopting forging and / or rolling equipment; and 7, annealing treatment. The preparation process has reasonable design, simple steps and convenient operation; the prepared iridium alloy material has favorable performance, high purity, fine crystalline grain, high strength at high temperature and less loss of precious metal in the preparation process; and the invention is particularly suitable for processing and manufacturing rare and precious metal materials.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

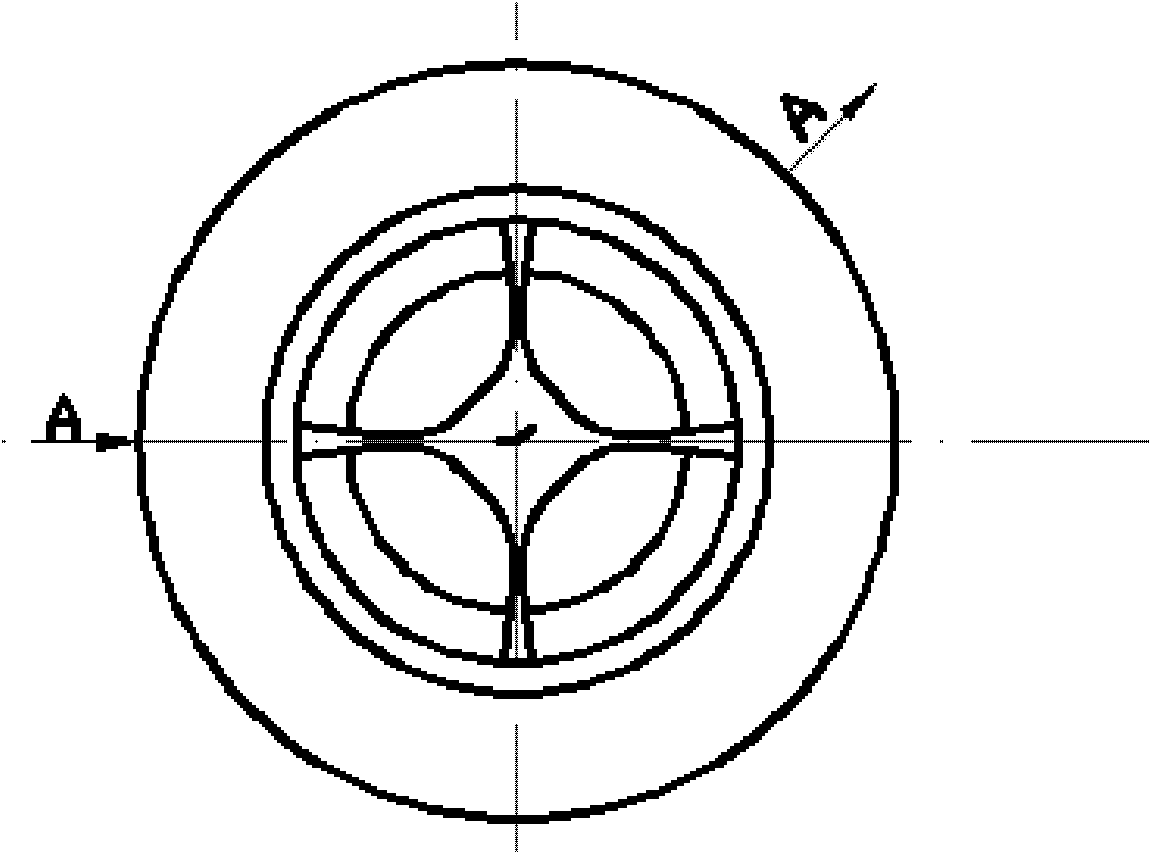

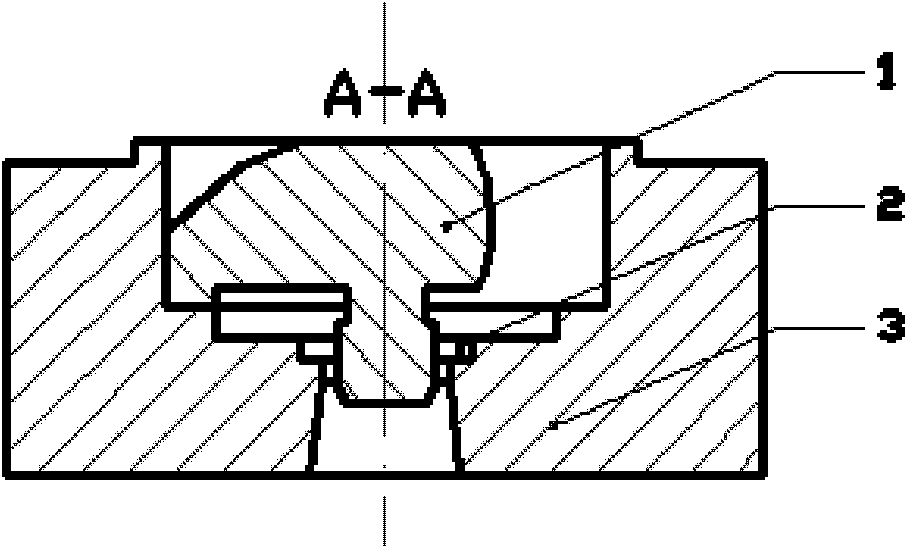

Continuous extrusion preparation process of a high-strength weldable zinc alloy and its pipe

The invention relates to a high-strength weldable zinc alloy, which is composed of the following components: aluminum, copper, titanium, magnesium, chromium, rare earth, and the balance is zinc. The preparation process of the pipe includes the following steps: batching, melting and casting; and continuous extrusion; the invention prepares a high-strength weldable zinc alloy by optimizing the ratio of alloy elements, and then continuously extrudes to form a zinc alloy pipe. The extrusion process does not need to heat the zinc alloy billet, so that the zinc alloy is directly formed in the mold by split extrusion through continuous large shear deformation. The composition ratio of the invention is reasonable, the prepared alloy material has good mechanical properties, is easy to realize extrusion forming, has good weldability, the raw material is cheap and easy to obtain, the preparation process design of the zinc alloy pipe is reasonable, the operability is strong, and the processing efficiency is high. It also solves the outstanding problems of the conventional pipe extrusion process, such as long process flow, high energy consumption, low material utilization rate, and high production cost, and has a good application prospect.

Owner:CENT SOUTH UNIV

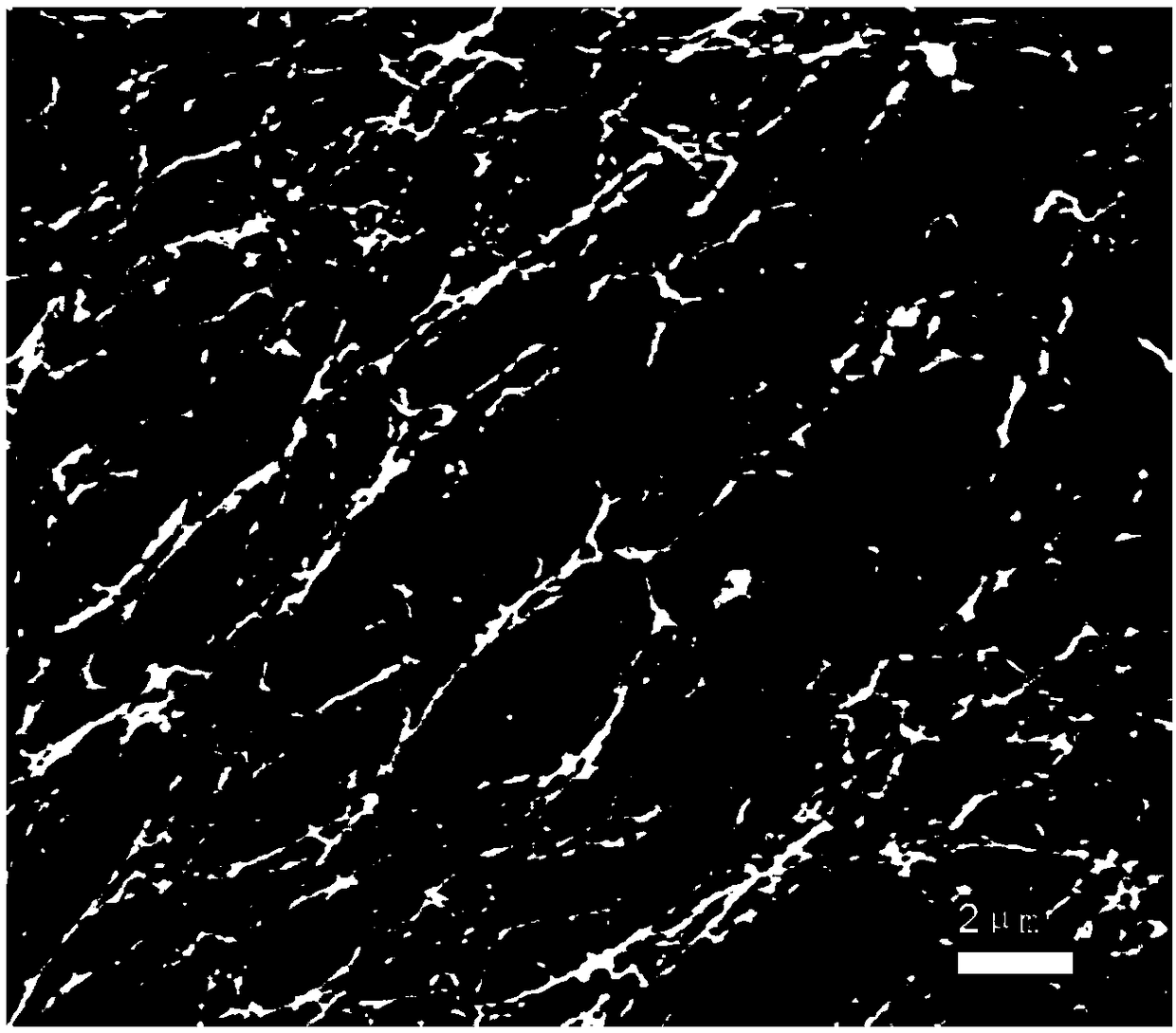

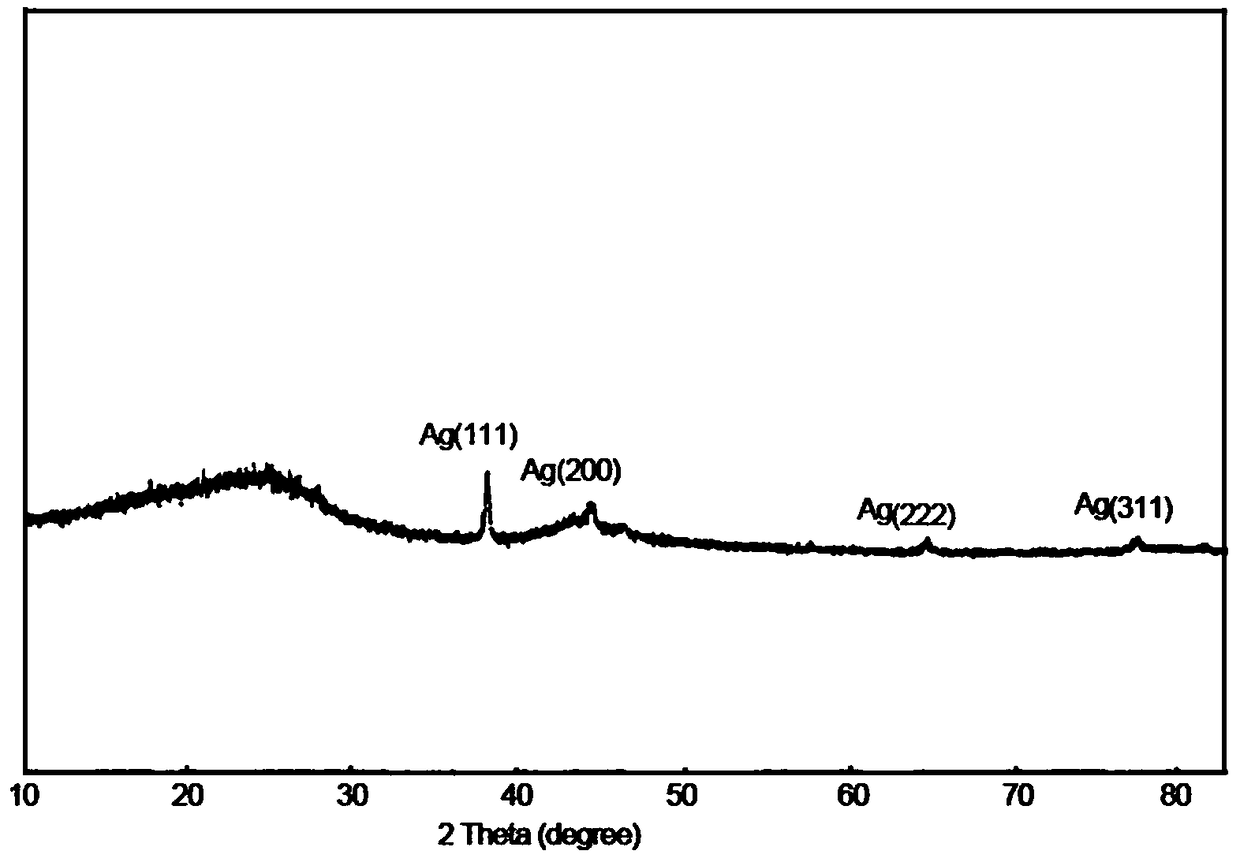

Antibacterial nanofiber and preparation method thereof

ActiveCN108951106AEliminate poor antibacterial abilityEliminate breeding defectsArtificial filaments from cellulose solutionsBiochemical fibre treatmentChemical treatmentCellulose

The invention discloses an antibacterial nanofiber and a preparation method thereof. The preparation method comprises: preparing cellulose nanofibers from biomass wood fibers through physical and chemical treatment, oxidizing the cellulose nanofibers through an oxidant solution to obtain oxidized nanofibers, putting the oxidized nanofibers in a silver-ammonia solution for a reaction and drying thefibers to obtain antibacterial nanofibers. The preparation method has a reasonable design, is easy to operate and prepares compact porous nanofibers with a high length-diameter ratio. The nanofiber can adsorb external bacteria and has antibacterial and antiseptic effects.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

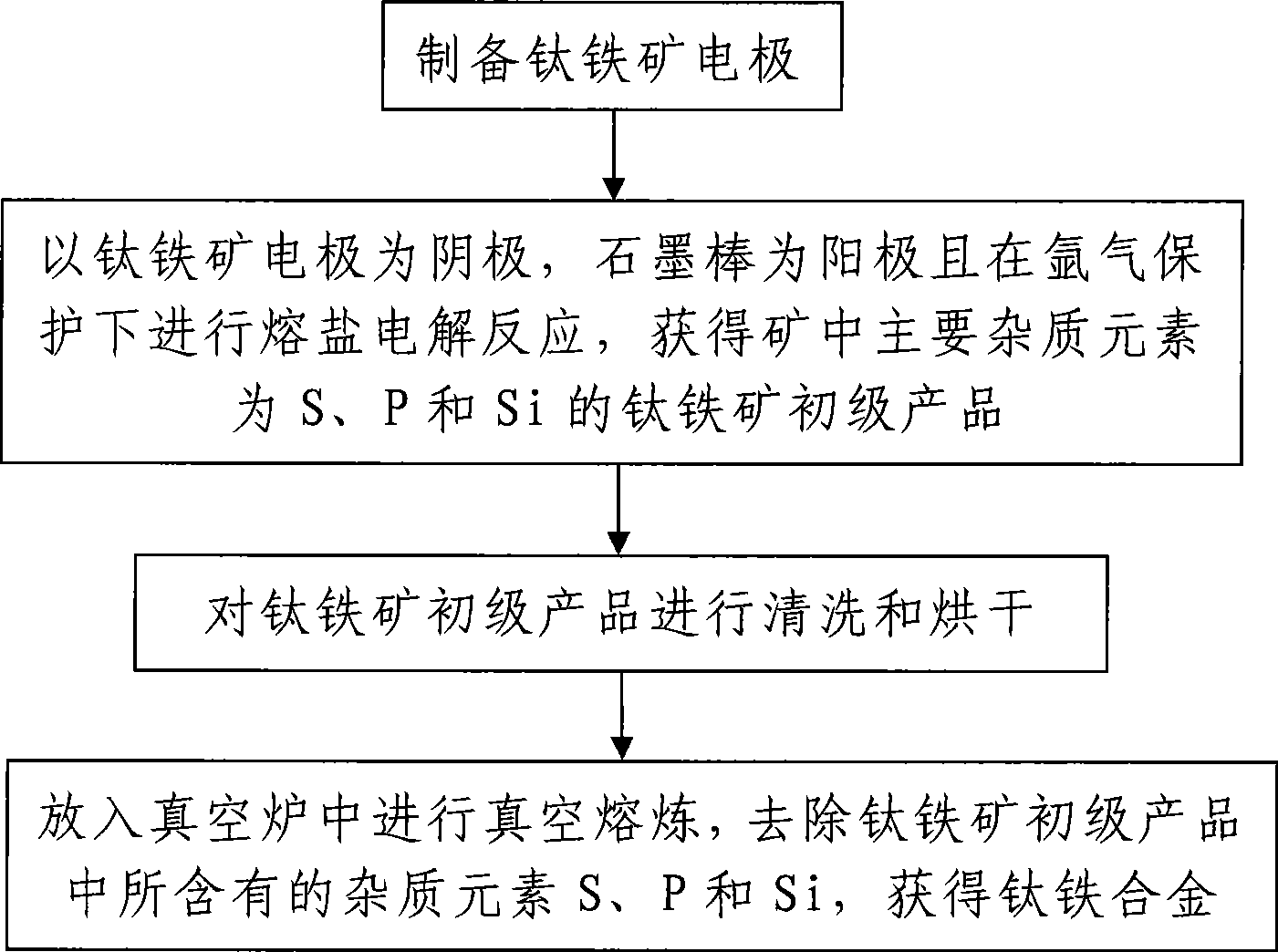

Method for producing titanium iron alloy with titanic iron ore

The invention discloses a method for preparing ferrotitanium with titanic iron ore, comprising the following steps: 1, preparing titanic iron ore electrode by crushing, evenly mixing, press-forming and high-temperature sintering the titanic iron ore raw material in the selected ore, of which the main impurity elements are P, S, Mg, Al, Ca, O and Si; 2, carrying out fused salt electrolysis by taking titanic iron ore electrode as the cathode, and graphite rod as the anode under the protection of argon to obtain the primary titanic iron ore product in which the main impurity elements are S, P and Si; and 3, vacuum melting the washed and dried primary titanic iron ore product in a vacuum furnace to remove the impurity elements of S, P and Si contained in the primary product so as to obtain the ferrotitanium. The method has simple preparing steps and convenient operation and low cost, can greatly reduce the energy consumption and environment pollution in metallurgy process and can effectively avoid waste of mineral resources.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

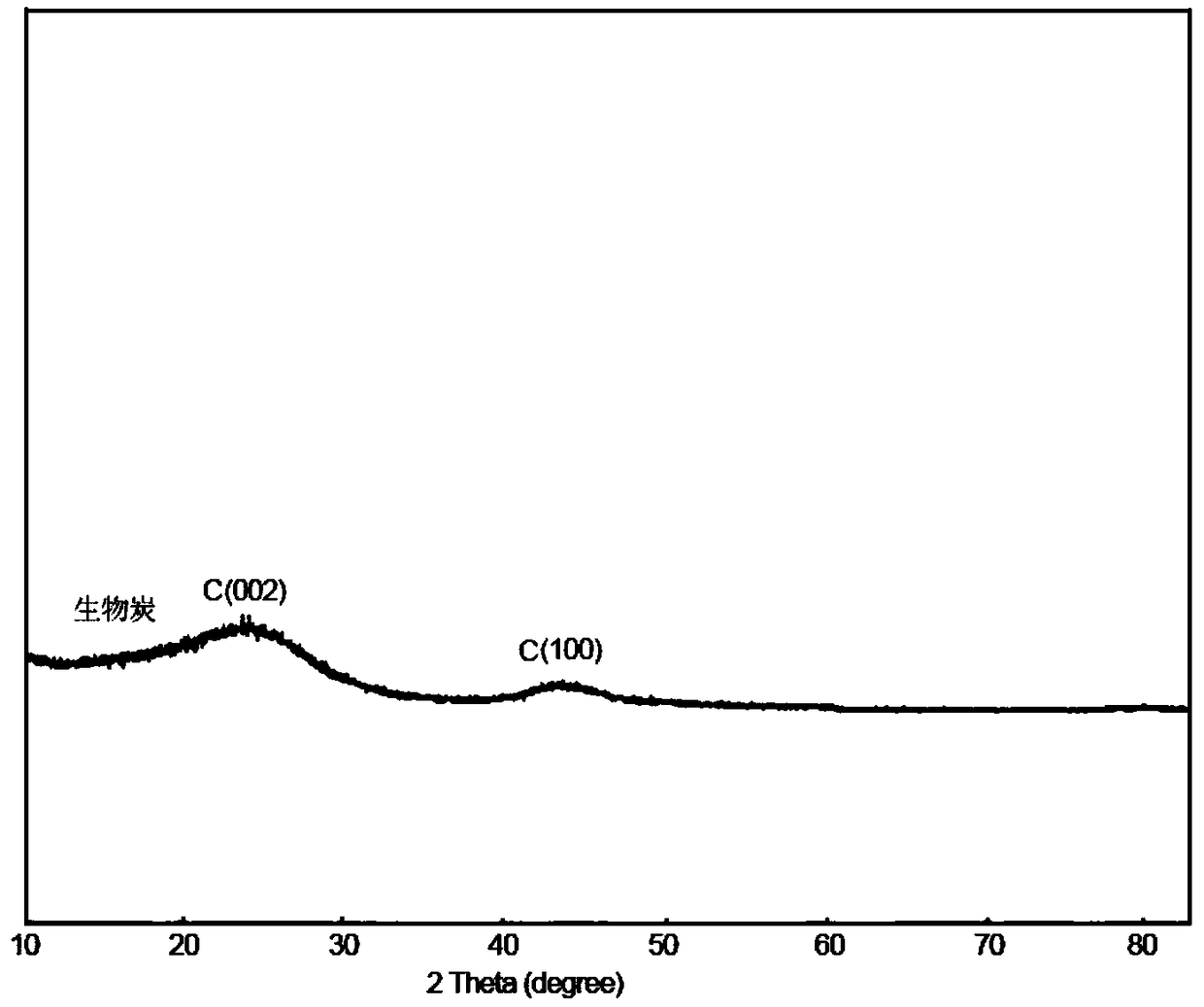

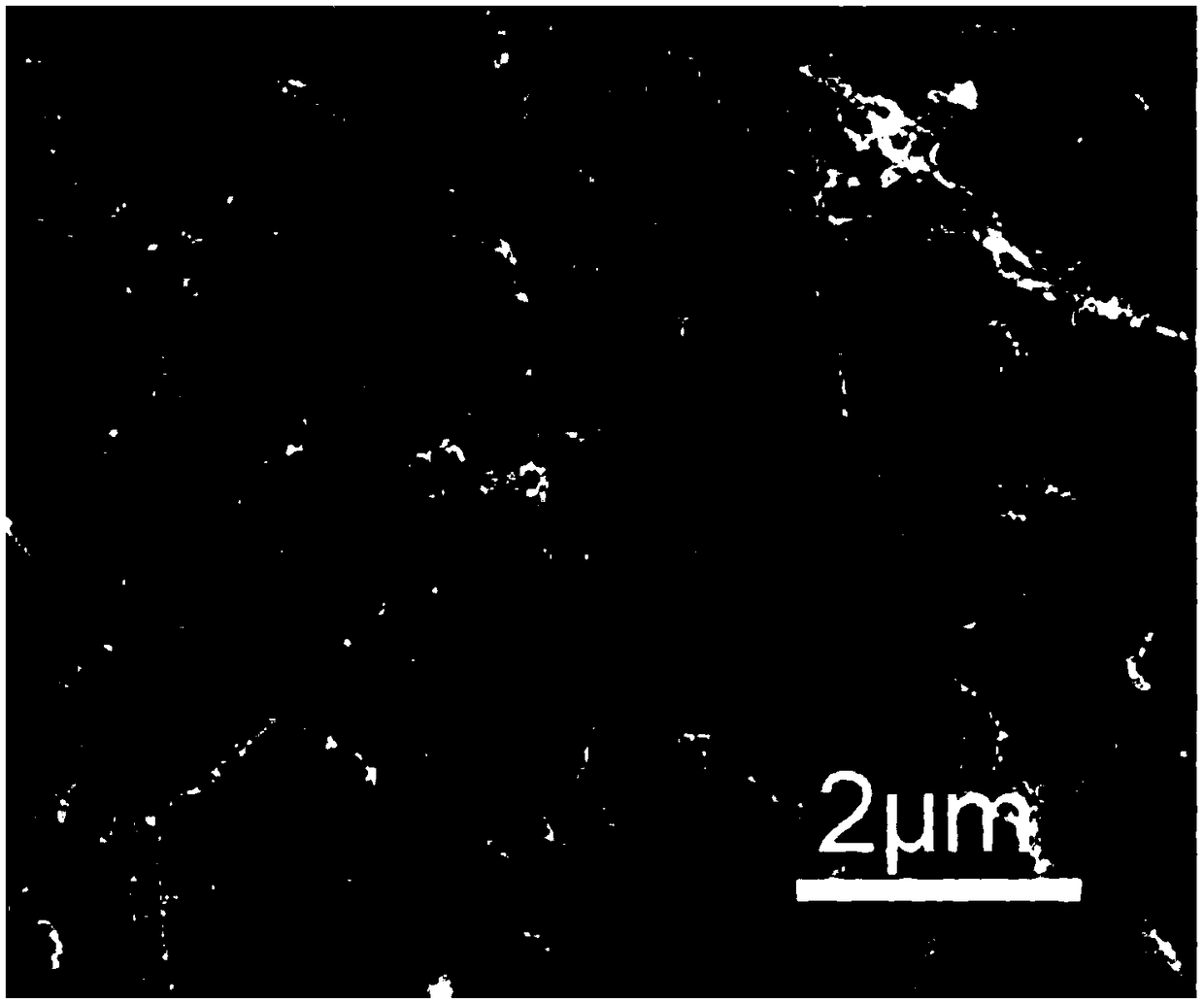

Wood biochar material capable of adsorbing heavy metals and preparation method thereof

InactiveCN108940192AExtended service lifeEliminate low porosityOther chemical processesAlkali metal oxides/hydroxidesChemical treatmentFiber

The invention discloses a wood biochar material capable of adsorbing heavy metals and a preparation method thereof. The preparation method comprises the following steps: selecting a wood biomass raw material; subjecting the biomass raw material to physical and chemical treatment so as to obtain a biomass nanofiber aerogel; then placing the biomass nanofiber aerogel in a shielding gas for high-temperature pyrolysis; and finally performing alkaline high-temperature activation so as to prepare the porous biochar fiber aerogel material. The preparation method of the invention is reasonable in process design and simple to operate; and a prepared biochar fiber aerogel is of a three-dimensional porous structure which not only improves adsorption efficiency but also prolongs the service life of the recycled biochar material.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

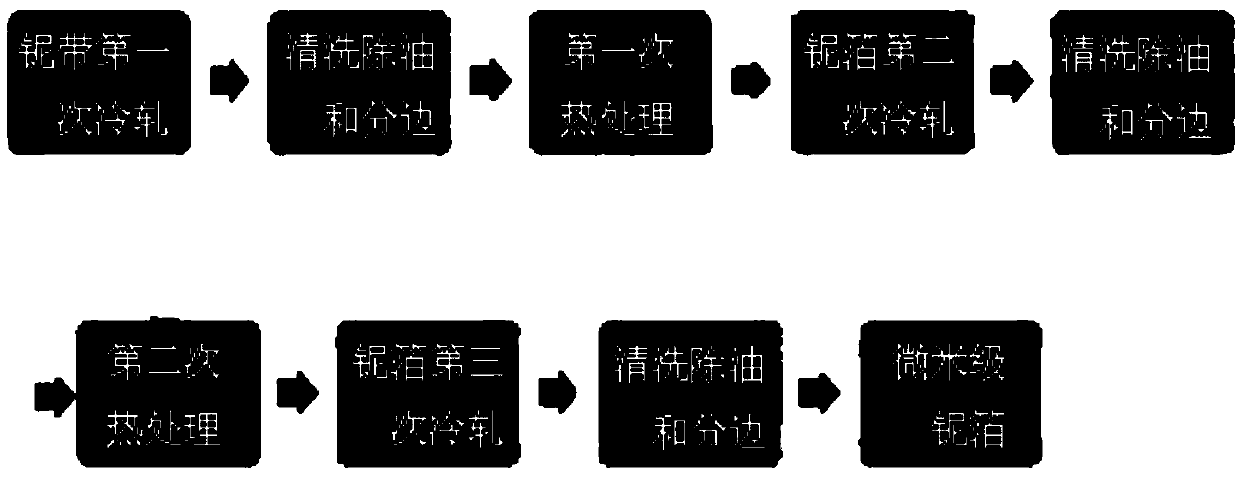

Preparation method of micro order niobium foil

The invention discloses a preparation method of a micro order niobium foil. According to the method, three rolling process reversible type rolling is performed on a niobium belt by utilizing a Sendzimir twenty-roller cold rolling machine, the obtained niobium foil is cleaned, and subjected to edge splitting and heat treatment after each rolling process reversible type rolling, and finally, the micro order niobium foil is obtained. According to the method, three rolling process rolling is performed on the niobium belt with the width being 100 mm to 120 mm and the thickness being 0.15 mm to 0.2mm by adopting the Sendzimir twenty-roller cold rolling machine. Due to the beneficial effects that the Sendzimir twenty-roller cold rolling machine is large in rolling force and high in rolling precision, by designing a reasonable rolling process, the thickness precision of the micro order niobium foil is greatly guaranteed; meanwhile, through a reasonable annealing process, the structure internal stress of the niobium foil is eliminated in time, influences on the niobium foil in the rolling process are reduced, and finally, the micro order niobium foil with the thickness being 0.007 mm to 0.009 mm is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Effervesce tablet for dredging thrombosis and its preparation process

InactiveCN1839861AReduce hardnessSolve the problem of long storage time and easy failureOrganic active ingredientsPill deliverySodium bicarbonatePolyethylene glycol

Each of the disclosed tablet contains Notoginsen triterpenes 25-100mg, lactin 100-415mg, tartaric acid 28-120mg, stevioside 5-20mg, polyethylene glycol 6000 12-50mg, sodium hydrogen carbonate 26-110mg, and magnesium stearate 1-5mg. The preparing process consists of (1) disintegrating and mixing the raw material, making soft material with ethanol, sieving and drying, (2) heating polyethylene glycol 6000, charging sodium hydrogen carbonate, stirring, cooling down and disintegrating, sieving, mixing with the obtained particles and magnesium stearate, (3) pelleting.

Owner:YUNNAN GULIN NATURAL PHARMA

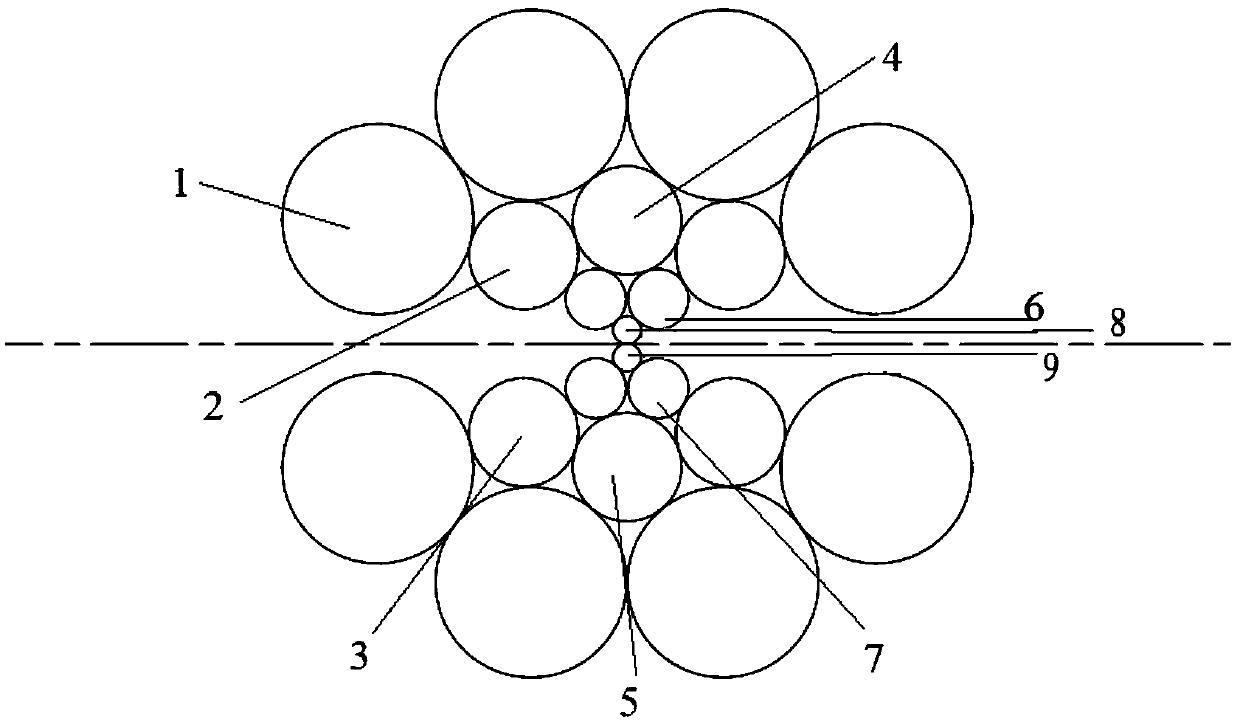

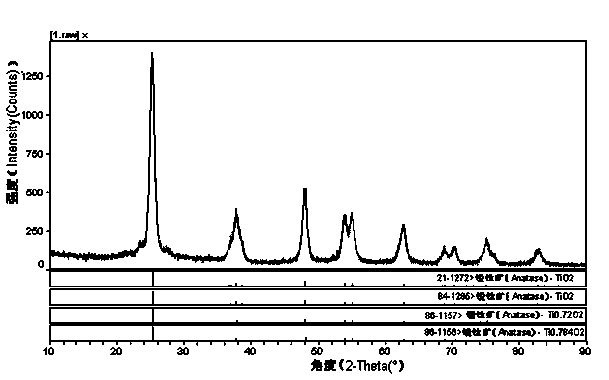

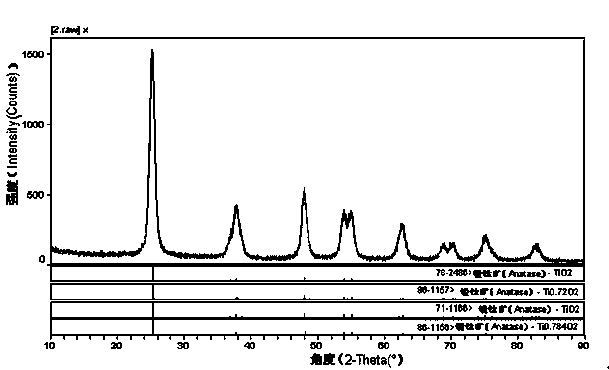

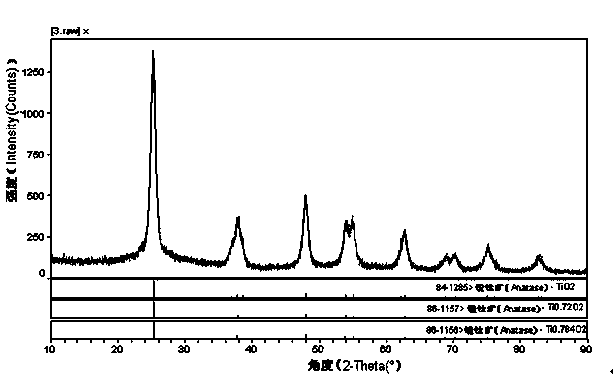

A kind of denitrification catalyst adding SiO2 and preparation method thereof

InactiveCN102921405BImprove anti-sintering performanceIncrease temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention belongs to the technical field of denitration catalysts, and in particular relates to a denitration catalyst added with SiO2 and a preparation method thereof. The mass percentages of each component in the denitration catalyst are as follows: V2O5 is 1%~2%, WO3 is 5%, and SiO2 is 5%~10%, and the rest is TiO2. The preparation method of the denitrification catalyst is to prepare TiO2-SiO2 composite carrier by co-precipitation method, one-step impregnation method to load V2O5 and WO3, and then the catalyst obtained by roasting has high denitrification rate at low temperature, and can significantly increase the overall mechanical strength and wear resistance of the catalyst. characteristics, and the use of silica sol as SiO2 silicon source is not only low in cost, but also can improve the mechanical properties of its processing, extrusion, molding and other processes in the actual production process.

Owner:CHONGQING UNIV +2

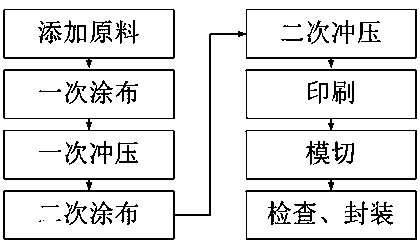

Manufacturing method of melamine impregnated paper

InactiveCN104532677AIncrease productionHigh bonding strengthNon-fibrous pulp additionPaper/cardboardMethyl aldehydeWear resistant

The invention belongs to the field of wood-based panel, and specifically relates to a manufacturing method of melamine impregnated paper. The manufacturing method comprises following steps: step 1, bacterial cellulose films are prepared; step 2, impregnated base paper with high strength is prepared; step 3, a softening melamine resin impregnation liquid is prepared; and step 4, the melamine impregnated paper is prepared, wherein the softening melamine resin impregnation liquid obtained via step 3 is delivered into an impregnator, surface impregnated wear-resistant paper or decorative impregnated paper is prepared via first impregnation, first drying, second impregnation, and second impregnation, and obtained products are stored in a special warehouse with constant temperature and humidity. The melamine impregnated paper is capable of satisfying using demands of laminate flooring; methyl aldehyde content and VOC content are reduced at the same time; indoor air pollution is improved; and the manufacturing method is of great significance on protection of human life and health.

Owner:NANTONG NEW CENTURY MECHANICAL & ELECTRICAL

Manufacturing method of melamine impregnated paper used for laminate flooring

ActiveCN104018394AIncrease productionHigh bonding strengthNon-fibrous pulp additionPaper/cardboardNitrogen sourceCasein hydrolysate

The invention discloses a manufacturing method of melamine impregnated paper used for laminate flooring. The manufacturing method comprises the following steps of preparing a bacterial cellulose membrane, preparing high strength impregnated body paper, softening a melamine resin and preparing the melamine impregnated paper. The manufacturing method takes mixed sugar as a carbon source and casein hydrolysate as a nitrogen source, so that output of the bacterial cellulose membrane is greatly increased. Isocyanate with high glue strength and good toughness is added in the softening process of the melamine resin; and the whole preparation process is reasonable in design and is scientific and controllable, so that preparation cost is reduced and physical properties of products are good, thereby meeting use requirements of the laminate flooring.

Owner:佛山简晟装饰材料有限公司

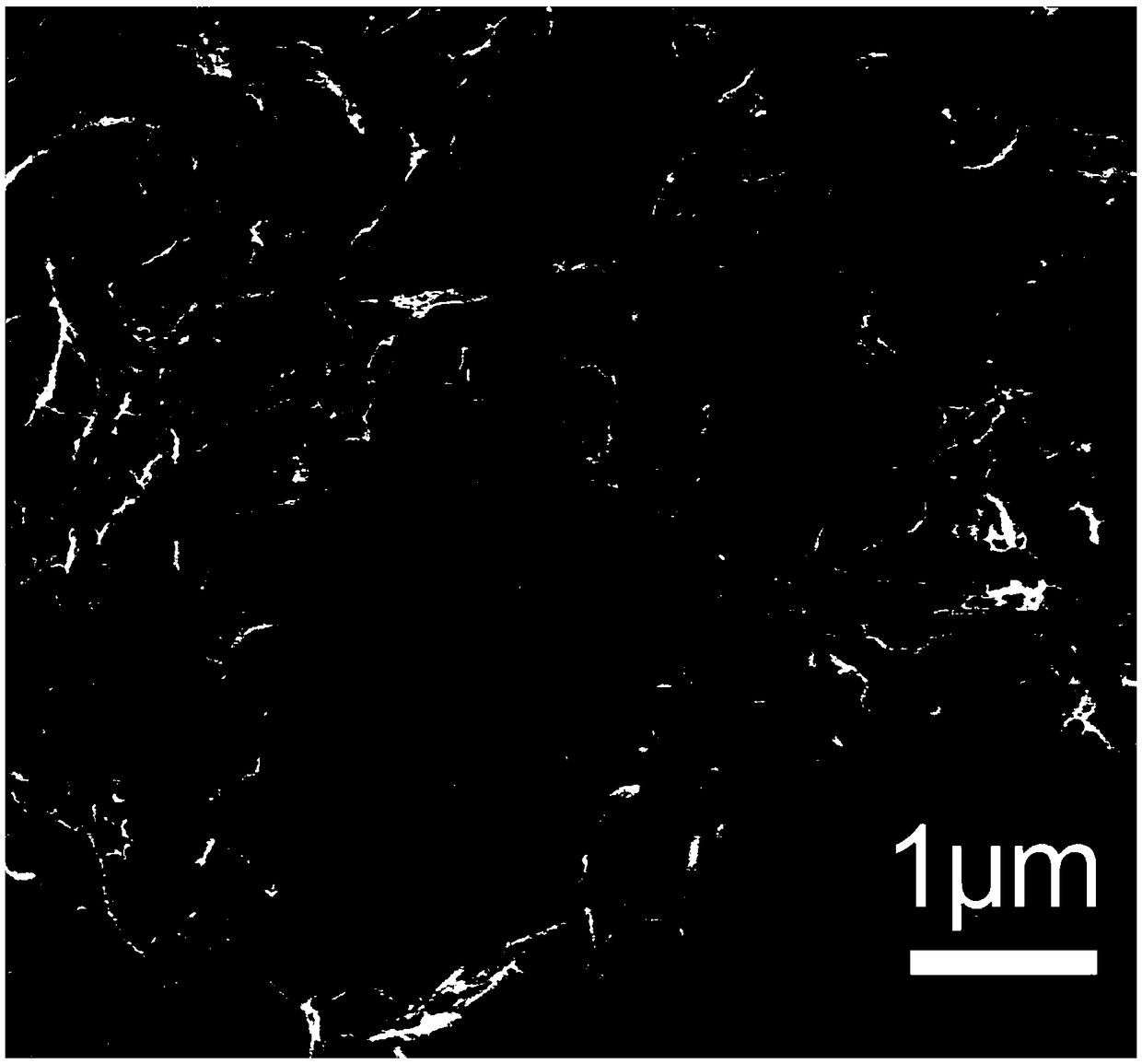

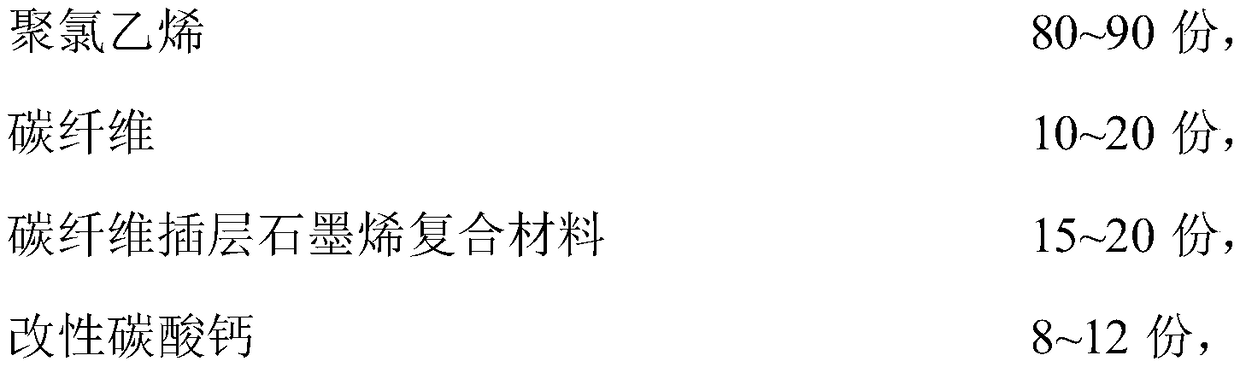

Lightweight high-strength carbon fiber graphene plastic pipe

InactiveCN108752794ASuitable for large-scale industrial productionGuaranteed high performance qualityFiberCarbon fibers

The invention discloses a lightweight high-strength carbon fiber graphene plastic pipe. The plastic pipe is prepared by the following raw materials by weight: 80-90 parts of polyvinyl chloride, 10-20parts of carbon fiber, 15-20 parts of carbon fiber intercalated graphene composite material, 8-12 parts of modified calcium carbonate, 0.5-1 part of acrylate, 0.8-1.5 parts of zinc stearate, 1-2 partsof antioxidant, 0.8-1.5 parts of lubricant and 0.5-1 part of stabilizer. The plastic pipe is formed by preparation of the carbon fiber; preparation of the carbon fiber intercalated graphene compositematerial; material mixing and extrusion molding. The preparation process is reasonable in design, simple, practical, not only suitable for large-scale industrial production of the plastic pipe, but also capable of ensuring high-performance quality of the plastic pipe, thereby being widely applicable to the fields of water supply and drainage systems, heating pipeline systems and gas transportation systems.

Owner:TAIZHOU UNIV

Production process of power-frequency encapsulated transformer

InactiveCN110164675AImprove qualityExtended service lifeEncapsulation/impregnationCoils manufactureCooking & bakingDoubling test

The invention belongs to the technical field of transformer application, and particularly discloses a production process of a power-frequency encapsulated transformer. The process comprises the following steps: 1, material taking; 2, primary winding; 3, secondary winding; 4, tin soldering; 5, appearance inspection; 6, turn-to-turn voltage withstand test; 7, silicon steel sheet assembling; 8, argonarc welding; 9, voltage withstanding test on a semi-finished product; 10, testing of the electrical performance of the semi-finished product; 11, assembling of a shell; 12, baking and drying; 13, automatic vacuum filling and sealing; 14, glue surface inspection; 15, inspecting of the appearance of a finished product; 16, frequency doubling and voltage doubling test of the finished product; 17, voltage withstanding test on the finished product; 18, testing of the electrical performance of the finished product; 19, packaging. The invention has the beneficial effects that the preparation processis reasonable in design; the prepared product is excellent in quality, long in service life and high in production efficiency; meanwhile, the rejection rate of the product is low, and the productioncost input of raw materials is saved.

Owner:NANJING ANSEN ELECTRONICS CO LTD

Carrageenan and konjac glucomannan special composite gum for meat products and preparation process thereof

The invention provides carrageenan and konjac glucomannan special composite gum for meat products and a preparation process thereof, the carrageenan and konjac glucomannan special composite gum comprises kappa carrageenan, konjac glucomannan and tetrapotassium pyrophosphate, the weight part addition ratio of kappa carrageenan to konjac glucomannan is 5: 5-9: 1, the added amount of the tetrapotassium pyrophosphate by weight is 10-20% of the total weight of kappa carrageenan and konjac glucomannan. The preparation process comprises the steps of wet mixing, drying, crushing and the like. The technical problems that in the prior art, carrageenan and konjac glucomannan are easy to flow when heated in meat products, and the synergistic effect is greatly weakened are solved. The preparation process is reasonable in design, the prepared carrageenan and konjac glucomannan special composite gel is high in strength and not prone to flowing after being heated, and meat products are high in quality in all aspects.

Owner:青岛海之林生物科技开发有限公司

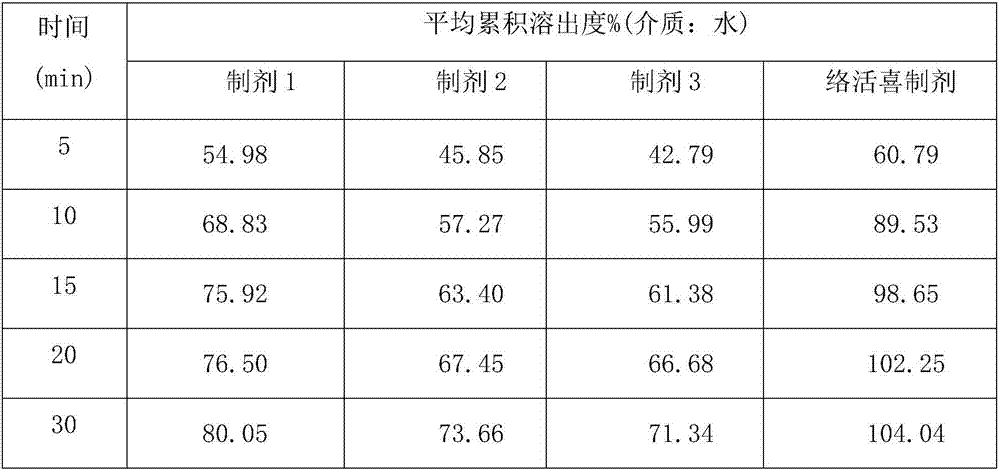

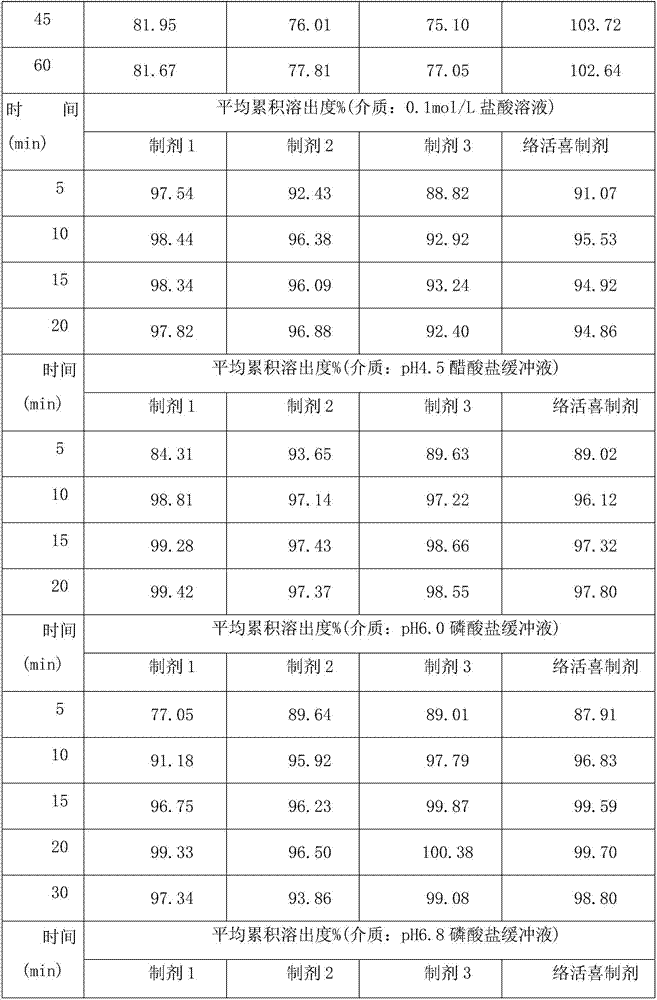

Preparation process of amlodipine besylate tablet

InactiveCN107362149AReasonable design of preparation processGuarantee product qualityOrganic active ingredientsPharmaceutical non-active ingredientsChronic stable anginaAmlodipine besilate

The invention discloses a preparation process of an amlodipine besylate tablet. The preparation process comprises the following steps: (1) material preparation process: the amlodipine besylate tablet is prepared from the following raw materials: amlodipine besylate, microcrystalline cellulose, starch, anhydrous calcium hydrophosphate, carboxymethyl starch sodium, starch paste, medicinal ethanol, magnesium stearate and talcum powder; (2) raw auxiliary material pretreatment process; (3) ingredient weighing process; (4) wet-process granulation process; (5) granulating and total mixing process; (6) tableting process; (7) aluminum plastic packaging process; (8) finished product packaging process. The preparation process of the amlodipine besylate tablet, disclosed by the invention, has the beneficial effects that the design is reasonable, the production process is normalized and standardized, and the product quality is ensured; the amlodipine besylate tablet prepared by the preparation process disclosed by the invention has an excellent treatment effect on essential hypertension, chronic stable angina and variant angina.

Owner:KANGBOSHI PHARMA LIAONING

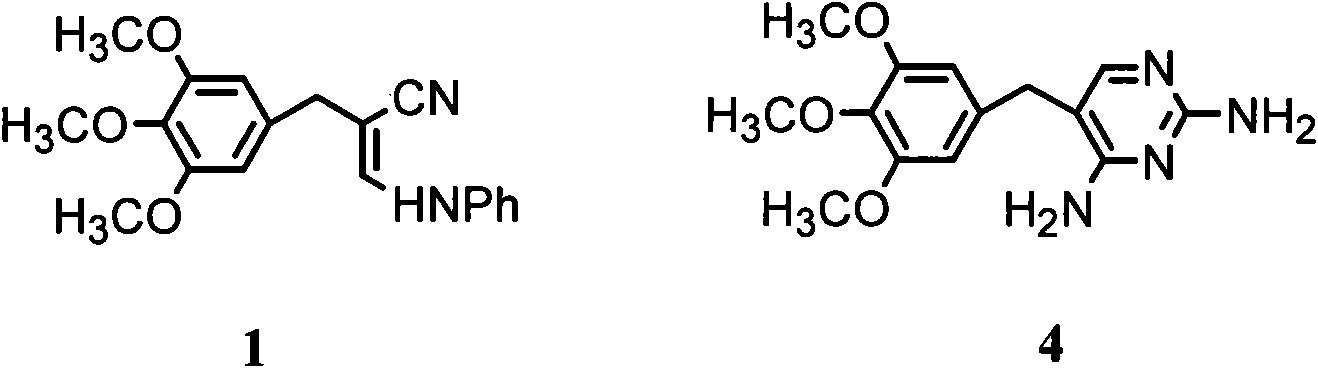

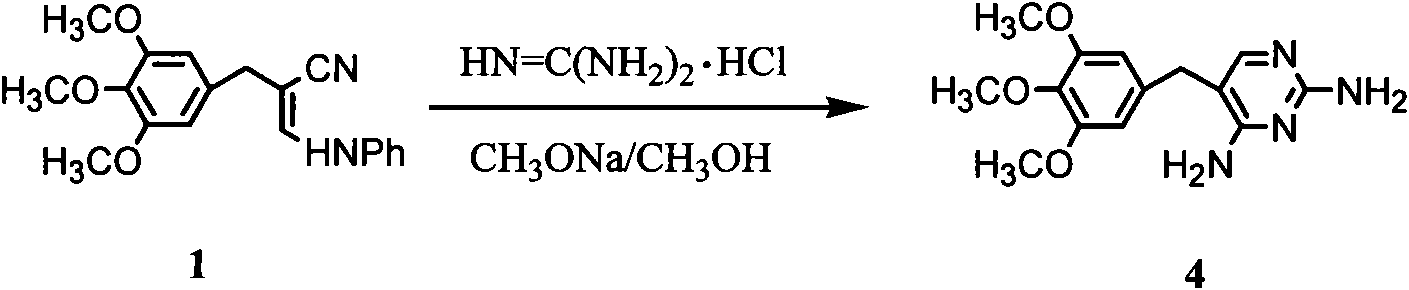

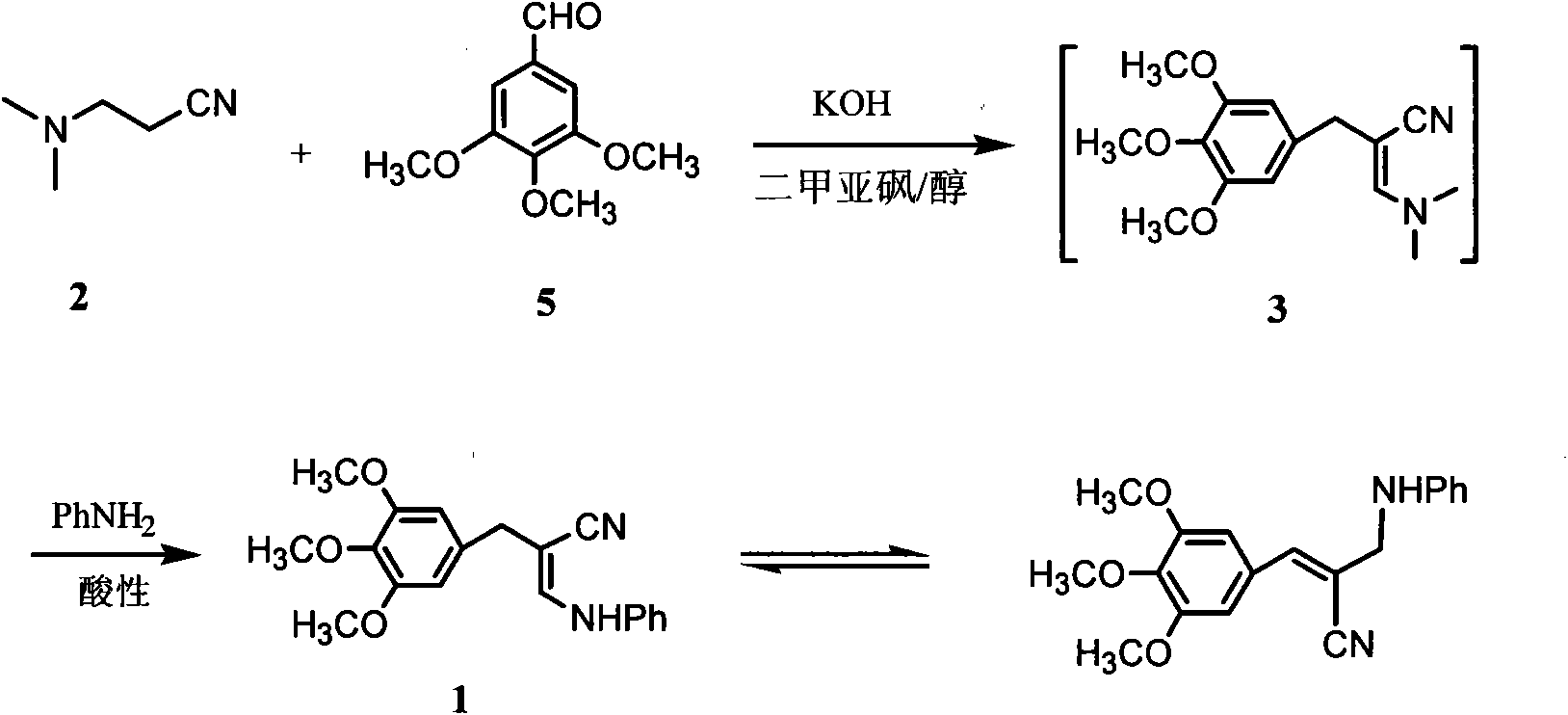

Preparation method of 3- anilino-2-(3,4,5-trimethoxy benzyl) acrylonitrile

InactiveCN101575303AHigh yieldReasonable design of preparation processCarboxylic acid nitrile preparationOrganic compound preparationBenzaldehydePotassium hydroxide

The invention discloses a preparation method of 3-anilino-2-(3,4,5-trimethoxy benzyl) acrylonitrile, which comprises the following steps: dissolving acrylonitrile derivative 3-dimethyl amino propionitrile and 3,4,5-trimethoxy benzaldehyde in an aprotic solvent, i.e. dimethyl sulfoxide, and adding a catalytic amount of alcoholic solution of potassium hydroxide; carrying out a first step of condensation reaction to generate 3-dimethylamino-2-(3,4,5-trimethoxy benzyl) acrylonitrile under the condition of heat; diluting the product after the condensation reaction with methyl alcohol, adding aniline with a catalytic amount, fully stirring, dropwise adding one of dilute sulphuric acid, diluted hydrochloric acid or acetic acid in the mixture until the pH value is 0.5-6.5 and heating the mixture for reaction to complete the second step of reaction of replacing dimethylamine functional groups by the aniline; after the reaction, steaming to eliminate the methyl alcohol in the system, freezing the system after adding an appropriate amount of water to 0-5 DEG C, separating out the 3-anilino-2-(3,4,5-trimethoxy benzyl) acrylonitrile which is a yellow solid product, and filtering and drying the product. The invention has the advantages of reasonable technology design, high yield, lower production cost, simple and convenient operation and convenient for mass production in industry.

Owner:EAST CHINA UNIV OF SCI & TECH

Production process of high-frequency and high-voltage encapsulation vacuum transformer

InactiveCN110111989AImprove qualityExtended service lifeEncapsulation/impregnationTransformerHigh pressure

The invention belongs to the technical field of transformer application, and particularly discloses a production process of a high-frequency high-voltage encapsulation vacuum transformer. The method comprises the following steps of: the step 1, material receiving; the step 2, laser marking of a shell; the step 3, primary winding; the step 4, secondary winding; the step 5, foot winding; the step 6,peeling of skin by a laser; the step 7, appearance inspection; the step 8, tin soldering; the step 9, appearance inspection; the step 10, assembling of a magnetic core; the step 11, electrical performance test of a semi-finished product; the step 12, assembling of a housing; the step 13, baking and drying; the step 14, automatic vacuum encapsulation; the step 15, inspection of glue surface; the step 16, appearance inspection of a finished product; the step 17, test of pressure resistance of the finished product; the step 18, electrical performance test of the finished product; and the step 19, package. The preparation process is reasonable in design, the prepared finished product is good in quality, long in service life and high in production efficiency of the product, the production process is reasonable in design, the product rejection rate is low, and the product cost input of raw materials is saved.

Owner:NANJING ANSEN ELECTRONICS CO LTD

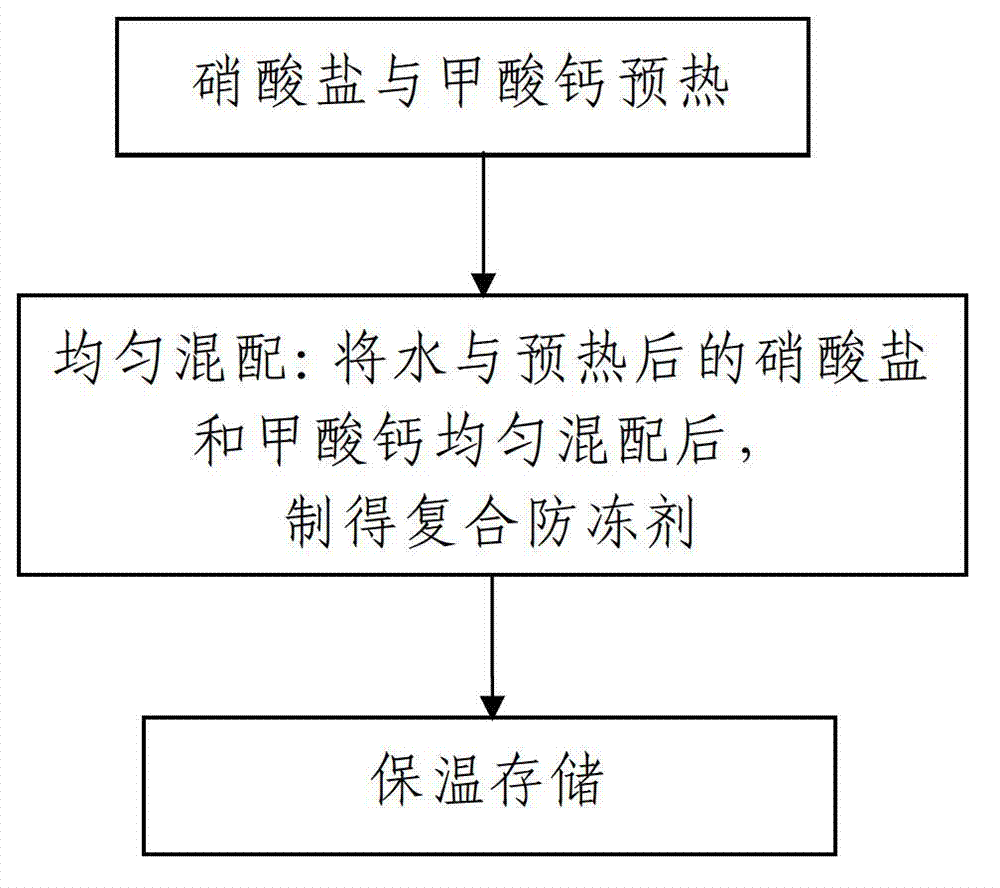

Ultralow temperature high-performance concrete composite anti-freezing agent and preparation technology thereof

The invention discloses an ultralow temperature high-performance concrete composite anti-freezing agent and a preparation technology for the ultralow temperature high-performance concrete composite anti-freezing agent. The composite anti-freezing agent comprises the following components in percentage by weight: 30 to 35% of nitrate, 30 to 33% of organic compound, 0.5 to 1% of calcium formate, and the balance of water, wherein the nitrate is calcium nitrate or calcium nitrite, and the organic compound is methanol or ethanol; and the preparation technology comprises the following steps: 1, preheating the nitrate and calcium formate: heating the nitrate and calcium formate to 40 to 70 DEG C, respectively; and 2, uniformly mixing: uniformly mixing the water and the heated nitrate and calcium formate in step 1 based on a design ratio, thus obtaining the composite anti-freezing agent. The preparation technology disclosed by the invention is simple in steps, simple and convenient to operate, has low input cost and a good using effect, and a performance of the ultralow temperature high-performance concrete can be effectively improved.

Owner:CHINA RAILWAY 20 BUREAU GRP

Formula of emulsified mixing oil

InactiveCN101328427AImproved vaporization rateFull and more even combustionRefining by water treatmentFuel oilPhenol

The invention relates to a formula of emulsified mixed oil. The formula consists of heavy oil, diesel oil, water and an addition agent, wherein the compositions in percentage by weight of the formula are: 69.9 to 29.9 percent of the heavy oil, 20 to 40 percent of the diesel oil, 10 to 30 percent of the water and 0.1 percent of the addition agent; moreover, the compositions in portion by weight of the addition agent are: 6 to 20 portions of manganese iso-octoate, 1 to 10 portions of nickel naphthenate, 35 to 65 portions of sorbitan monooleate, 4 to 8 portions of sorbitan polyoxyethylene monooleate, 1 to 2 portions of nonyl phenol polyoxyethylene (6) ether, 4 to 8 portions of sodium hydroxide, 4 to 6 portions of xylene, 1 to 6 portions of methanol and 1 portion of sunset red. The formula has the advantages that: the formula has reasonable proportioning, advanced technological method, low product price and high stability, and capability of replacing the diesel oil.

Owner:陈金义

Formula of biomass emulsified diesel oil

InactiveCN101328424AThe formula is scientific and reasonableReasonable design of preparation processRefining by water treatmentBiomassEffective energy

The invention relates to a formula of biomass emulsified diesel oil. The formula is characterized in that: the formula consists of heavy oil, diesel oil, water and an addition agent, wherein the compositions in percentage by weight of the formula are: 56 to 90 percent of the diesel oil, 5 to 25 percent of the water and 5 to 18 percent of the addition agent; moreover, the compositions in percentage by weight of the addition agent are: 9.9 to 69.9 percent of fatty acid, 25 to 85 percent of oleic acid, 4 to 14 percent of ethanolamine, 0.5 to 4 percent of isoamyl alcohol, 0.1 to 3 percent of sulfanilate and 0.5 to 10 percent of sorbitol monoester. The formula has the advantages that: the formula has reasonable proportioning, and the product does not have side effect on a machine body, has effective energy conservation and high stability, and can replace diesel oil.

Owner:陈金义

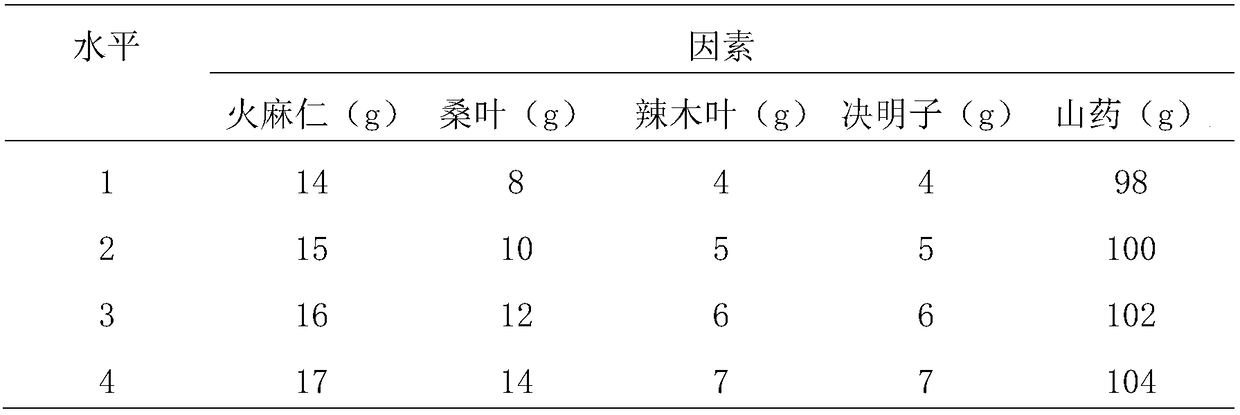

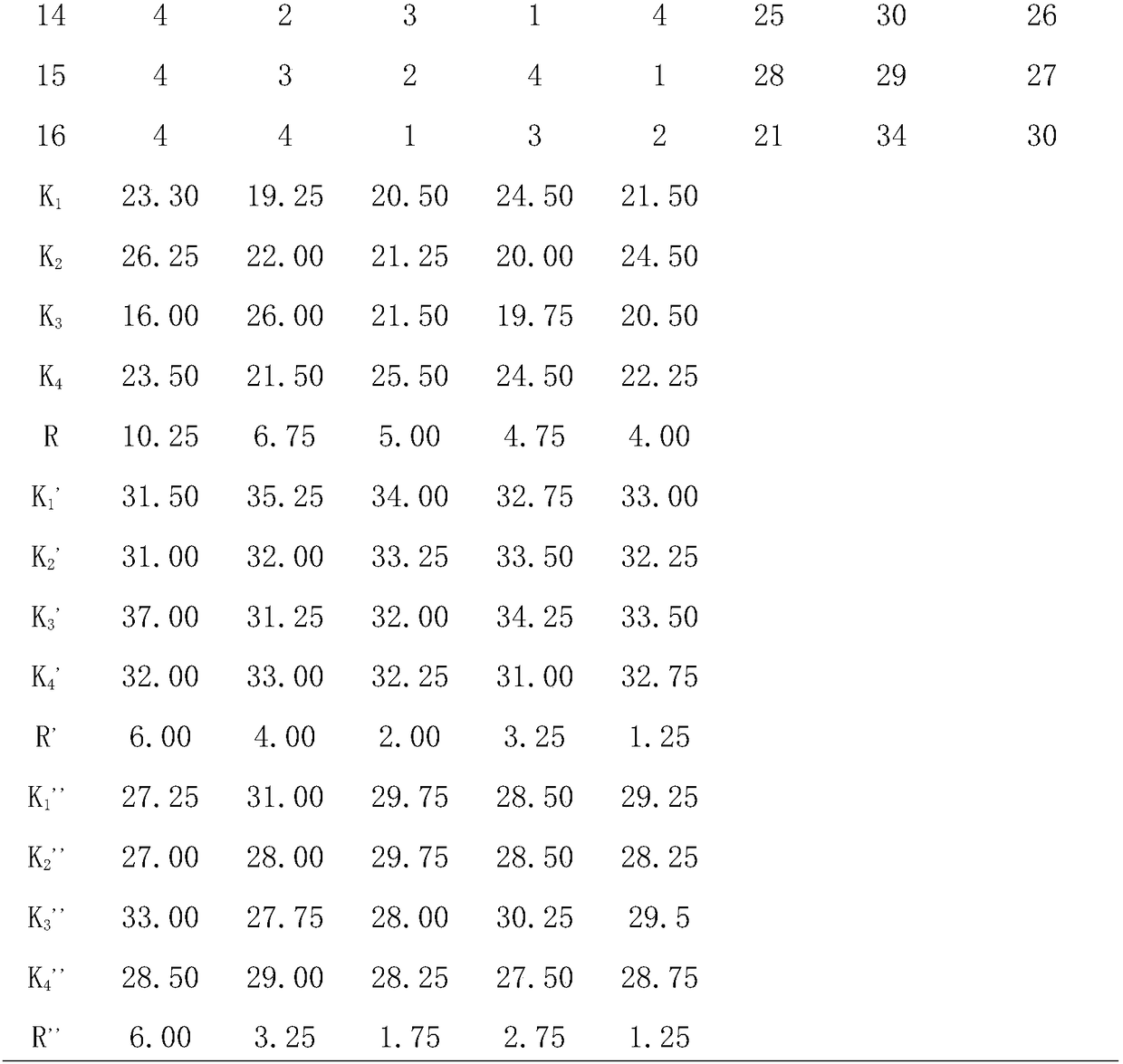

Solid beverage for regulating blood fat and preparation method thereof

The invention provides a solid beverage for regulating blood fat and a preparation method thereof. The beverage comprises the following traditional Chinese medicine raw materials in parts by weight: 8-26 parts of hemp seeds, 4-20 parts of mulberry leaves, 2-16 parts of horseradish tree leaves, 2-16 parts of cassia seeds and 80-120 parts of Chinese yams. The preparation method comprises the steps of crushing, drying, packaging and the like. An extrusion puffing process is the optimal drying process, and the optimal process parameter combination is as follows: raw material particle size is 100-mesh; raw material moisture content is 16 percent; the puffing temperature is 150 DEG C; and screw speed is 160 r / min. The method solves the technical problem that solid beverages in the prior art forregulating blood fat are low in sensory score and poor in stability. The method is reasonable in experimental design; the prepared finished product is high in sensory score and good in stability; themethod improves the quality of the solid beverage for regulating blood fat and realizes homology of medicine and food; and the beverage is simple, convenient, safe, effective, and free from toxic or side effect.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

Novel tablet candies capable of regulating blood pressure and preparation method thereof

InactiveCN108541800AEfficient screeningMatching ratios were screened quicklyConfectionerySweetmeatsSide effectMagnesium stearate

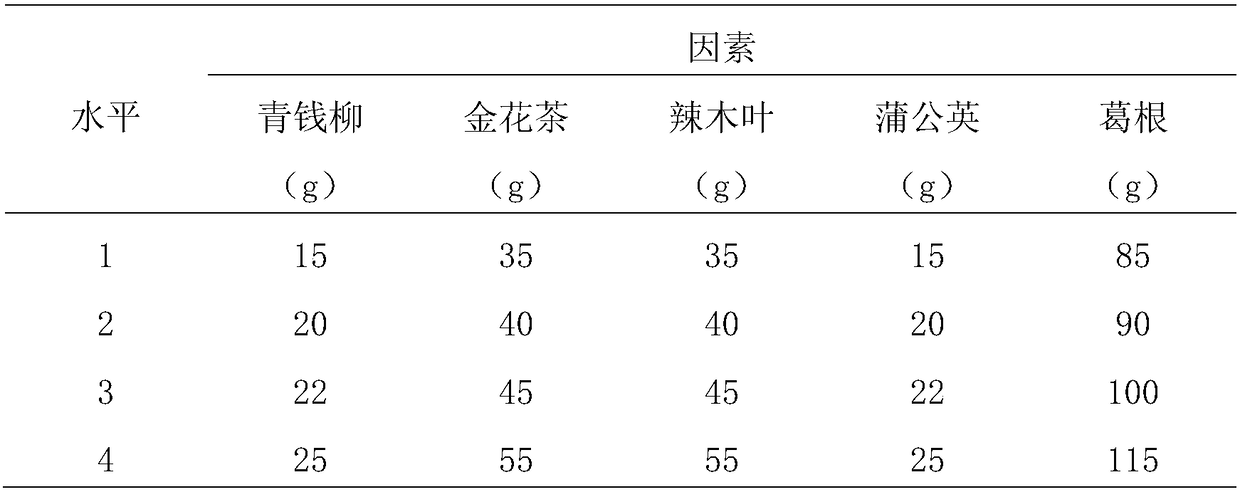

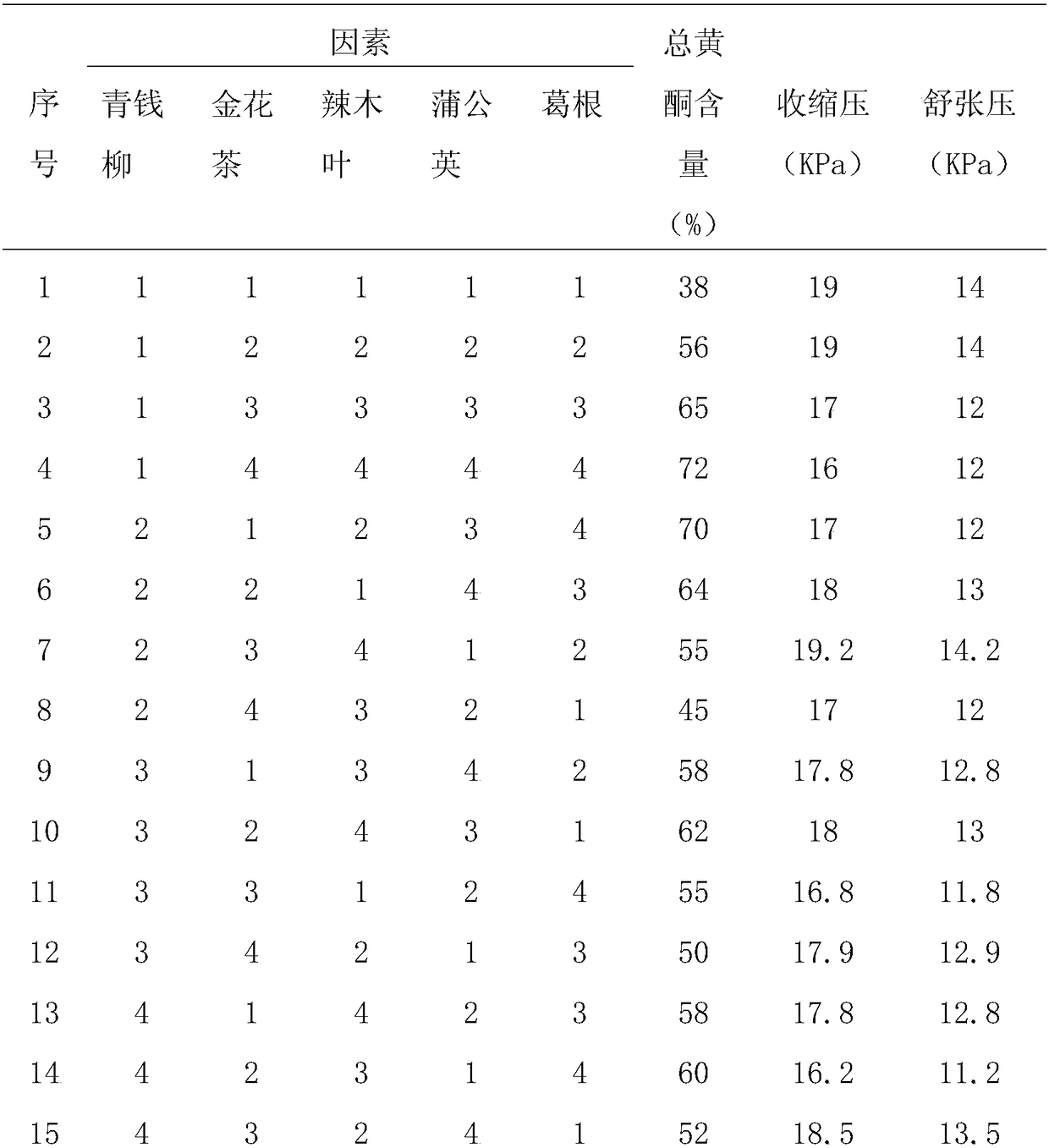

The invention provides novel tablet candies capable of regulating blood pressure and a preparation method thereof. The novel tablet candies capable of regulating blood pressure are prepared from 15-25parts by weight of cyclocarya paliurus, 35-55 parts by weight of golden camellia, 35-55 parts by weight of moringa leaves, 15-25 parts by weight of mongolian dandelion herb, 85-115 parts by weight ofkudzuvine roots, 10-30 parts by weight of glucose powder, 10-30 parts by weight of maltodextrin, 2-6 parts by weight of citric acid, 10-15 parts by weight of magnesium stearate, and 2-6 parts by weight of menthol. The preparation method of the novel tablet candies capable of regulating blood pressure comprises the following steps of carrying out extracting, carrying out concentrating, carrying out drying, carrying out tablet-compressing and so on; and the best extraction conditions are as follows: the water volume is 1.5 liters, extraction is performed for 4 times, and extraction each time isperformed for 1 hour. The novel tablet candies capable of regulating blood pressure solve the technical problems of novel blood-pressure-regulating tablet candies in the prior art, namely low contentof total flavonoids as an active ingredient, poor curative effects and so on. The preparation method of the novel tablet candies capable of regulating blood pressure is rational in experimental design; and the prepared finished products are high in total flavonoid content and good in stability. And thus, the prepared novel tablet candies capable of regulating blood pressure have improved quality,and are simple and convenient to use, safe, effective, and free of toxic and side effects.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

Preparation method of marinating material for marinated eggs

InactiveCN108740929AIncrease profitExtended shelf lifeFood preservationFood ingredient as taste affecting agentWild mushroomSugar

The invention discloses a preparation method of a marinating material for marinated eggs. The preparation method utilizes base raw materials and seasoning bag raw materials such as 1 to 2 parts of hawthorn slices, 3 to 5 parts of Chinese prickly ash, 10 to 15 parts of rice wine, 1 to 2 parts of radix curcumae, 0.2 to 0.4 parts of radix glycyrrhizae preparata, 0.1 to 0.4 parts of dried ginger slices, 3 to 5 parts of anise, 0.1 to 0.2 parts of allicin, 5 to 15 parts of brown sugar, 15 to 20 parts of lotus leaf, 5 to 10 parts of wild mushroom and 5 to 10 parts of fresh mint. The preparation method comprises: crushing the base materials, stir-frying the base materials at a high temperature, immersing the seasoning bag in boiling water and carrying out packaging to obtain the marinating material. The preparation method processes the raw materials, improves the raw material use rate and makes the best use of everything. The marinating material is delicious, is not greasy after long-term use,prevents inflammation and has a long preservation period. The preparation method is simple and utilizes a marinating raw material ratio designed based on the theory of traditional Chinese medicine and the existing cooking technology. The marinated eggs prepared through the marinating material do not contain harmful components and have a fresh taste.

Owner:成都市恒业生态农业有限公司

Production process of low-frequency common mode choke

InactiveCN110136944AImprove qualityExtended service lifeInductances/transformers/magnets manufactureCooking & bakingElectricity

The invention belongs to the technical field of application of a low-frequency common mode choke and discloses a production process of the low-frequency common mode choke. The production process comprises the following steps: 1) material collection, preparation before production and preparation of all raw materials required for production of claimed products; 2) primary side winding; 3) secondaryside winding; 4) foot winding; 5) soldering; 6) appearance inspection; 7) magnetic core assembly; 8) magnetic core fixation; 9) electrical performance inspection of semi-finished products; 10) insulating varnish dipping; 11) baking and drying; 12) appearance inspection of finished products; 13) withstand voltage test of the finished products; 14) electrical performance inspection of the finished products; and 15) packaging. The beneficial effects are that the preparation process is reasonable in design; the prepared low-frequency common mode choke is excellent in quality and long in service life, and product production efficiency is high; and meanwhile, through the reasonably designed production process, product rejection rate is low, and raw material production cost is saved.

Owner:NANJING ANSEN ELECTRONICS CO LTD

Solid polyester modified silicon resin for heat-resisting powder paints and preparation method thereof

InactiveCN107254050AHigh synthesis efficiencyHigh glossFireproof paintsPowdery paintsTrimethylolpropaneNeopentyl glycol

The invention discloses a solid polyester modified silicon resin for heat-resisting powder paints and a preparation method thereof. The solid polyester modified silicon resin for the heat-resisting powder paints is obtained through reaction of a polyester prepolymer and a silicon intermediate, wherein the polyester prepolymer is prepared from trimethylolpropane, neopentyl glycol, phthalic anhydride, trimellitic anhydride and pentaerythritol; the silicon intermediate is prepared from methyltrichlorosilane, dimethyldichlorosilane, phenyltrichlorosilicane, diphenyl dichlorosilane and propylene glycol methyl ether acetate. The solid polyester modified silicon resin for the heat-resisting powder paints is prepared from the optimal raw material composition and ratio obtained by a large number of experiments; by optimizing synthesizing processes, the entire preparation process is reasonable in design and high in operability and synthesizing efficiency; the softening point of the prepared solid polyester modified silicon resin is around 90-105 DEG C, the heat-resisting powder paints prepared from the solid polyester modified silicon resin can resist high temperature of 55-650 DEG C and are excellent in heat-resisting performance, high in glossiness and wide in application range. The solid polyester modified silicon resin for the heat-resisting powder paints obtains high technical effects and overcomes the deficiencies in the prior art.

Owner:江苏三木化工股份有限公司 +1

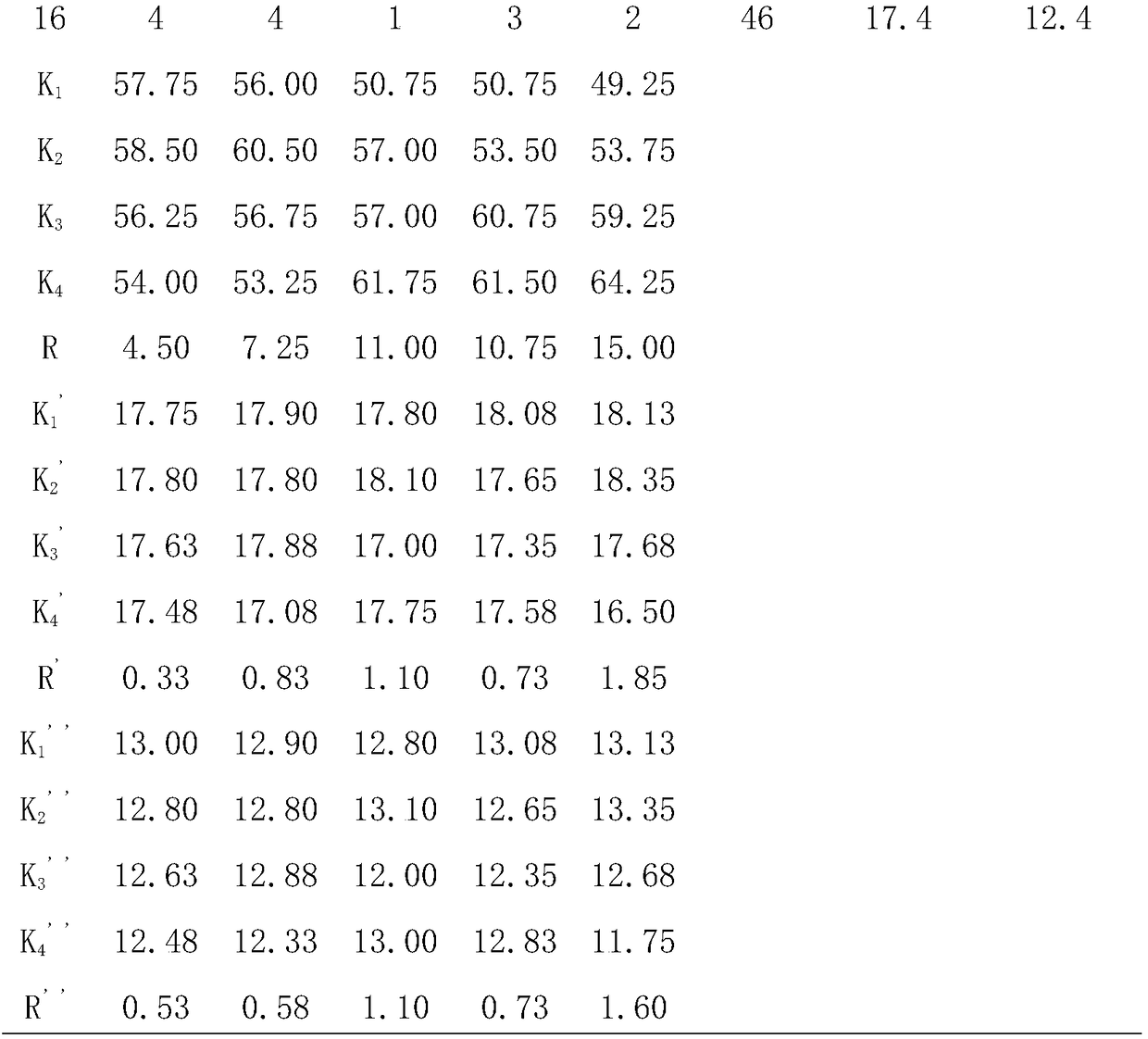

Synthesis production process of difluorochloroacetic acid

ActiveCN105859540AReasonable design of preparation processHigh absorption rate and total yieldChlorine/hydrogen-chloridePreparation from carboxylic acid halideChemistryEnvironmental resistance

The invention discloses a synthesis production process of difluorochloroacetic acid, comprising the following steps: charging sulfur trioxide with nitrogen gas into an oxidation reaction kettle by an intermittent process, starting stirring; after reaching a certain temperature, adding difluorotetrachloroethane and catalyst according to a predetermined ratio into the oxidation reaction kettle; heating for reaction, observing the backflow condition, starting steaming the byproduct sulfuric chloride when the kettle temperature rises to a certain temperature while the backflow is small; after steaming the byproduct sulfuric chloride, carrying out charging for the second time; carrying out three-stage spray hydrolysis and absorption on the product difluorochloracetyl chloride to generate crude product difluorochloroacetic acid, and carrying out defluorination and rectification on the crude product to obtain finished product difluorochloroacetic acid. The synthesis production process of difluorochloroacetic acid disclosed by the invention adopts the difluorotetrachloroethane as a raw material, the finished product difluorochloroacetic acid is prepared by oxidation reaction, the preparation process has reasonable design, high absorption rate, high overall yield and low energy consumption; and the byproduct can be hydrolyzed and reused, so that the production process is clean, environment-friendly, safe and reliable.

Owner:NANTONG BAOKAI CHEM

Transformer silicon steel sheet stacking and welding method

InactiveCN111261399AIncrease productivityReduce production cost inputInductances/transformers/magnets manufactureWelding accessoriesMaterials preparationTransformer

The invention belongs to the technical field of transformer silicon steel sheet application, and particularly discloses a transformer silicon steel sheet stacking and welding method. The method comprises the steps 1, preparing materials; 2, stacking E-shaped sheets; 3, assembling the E-shaped sheets, specifically, putting the stacked E-shaped silicon steel sheets into a middle hole of a transformer framework, and paying attention to that the loading direction cannot deviate or incline so as to prevent the silicon steel sheets from damaging enameled wires for winding a coil in the framework andbreaking the wires; 4, stacking and assembling I-shaped sheets, stacking the I-shaped silicon steel sheets according to the stacking thickness of the E-shaped silicon steel sheets, and then placing the I-shaped silicon steel sheets on the E-shaped silicon steel sheets; 5, welding the silicon steel sheets; and 6, conducting weld joint inspection. The transformer silicon steel sheet stacking and welding method has the beneficial effects that the preparation process is reasonable in design, the stacking and welding production efficiency of silicon steel sheet products is high, the protection process is reasonably designed at the same time, product rejection rate is low, the raw material production cost input is also saved, and the manufactured products are excellent and stable in quality.

Owner:NANJING ANSEN ELECTRONICS CO LTD

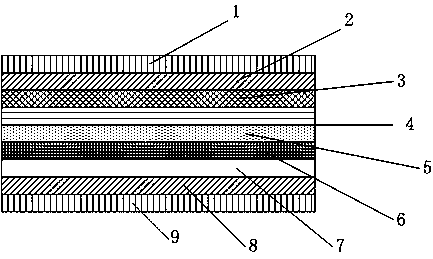

Protective film for liquid crystal display and preparation process of protective film

InactiveCN110757902AReasonable design of preparation processSimple structureSynthetic resin layered productsLiquid-crystal displayAcrylic adhesive

The invention discloses a protective film for liquid crystal display and a preparation process of the protective film. The protective film for liquid crystal display comprises a first ink layer, a first PET release film, a silica gel layer and the like, wherein the bottom surface of the first ink layer is connected with the top surface of the first PET release film, the bottom surface of the firstPET release film is connected with the top surface of the silica gel layer, and the bottom surface of the silica gel layer is connected with the top surface of a PU adhesive layer; the bottom surfaceof the PU adhesive layer is connected with the top surface of a PET base material, the bottom surface of the PET base material is connected with the top surface of an acrylic adhesive layer, and thebottom surface of the acrylic adhesive layer is connected with the top surface of a scratch-resistant adhesive layer; and the bottom surface of the scratch-resistant adhesive layer is connected with the top surface of a second PET release film. The protective film has reasonable design, a simple structure, excellent electric insulativity, resistance to high temperature and friction and good stability, requirements of different customers can be met, a protective film attaching procedure can be eliminated, the efficiency can be improved, and the cost is saved; and the problem that the protectivefilm falls off from the film periphery can be solved, and the protective film can be applied to high-temperature conditions, curved surface occasions and other special application fields.

Owner:苏州恒悦新材料有限公司

Formula of emulsified heavy oil

InactiveCN101328426AFull and more even combustionReduce contentRefining by water treatmentFuel oilSorbitan

The invention relates to a formula of emulsified heavy oil. The formula consists of heavy oil, water and an addition agent, wherein the compositions in percentage by weight of the formula are: 69.9 to 89.9 percent of the heavy oil, 10 to 30 percent of the water and 0.1 percent of the addition agent; moreover, the compositions in portion by weight of the addition agent are: 6 to 20 portions of cobalt iso-octoate, 6 to 20 portions of manganese iso-octoate, 1 to 10 portions of nickel naphthenate, 35 to 65 portions of sorbitan monooleate, 4 to 8 portions of sorbitan polyoxyethylene monooleate, 1 to 2 portions of nonyl phenol polyoxyethylene (6) ether, 4 to 8 portions of sodium hydroxide, 2 to 4 portions of xylene, 1 to 6 portions of methanol and 1 portion of sunset red. The formula has the advantages of reasonable proportioning, advanced technological method, low price, high stability and catalytic and combustion-supporting effects.

Owner:陈金义

Popular searches

Improve mechanical properties Easy to process Good market application prospect Good social and economic benefits Make up for performance deficiencies Reduce manufacturing cost Improve antistatic performance Completely hydrolyzed Improve hydrolysis efficiency Suitable for industrialized mass production

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com