Lightweight high-strength carbon fiber graphene plastic pipe

A technology of graphene plastic pipe and carbon fiber, which is applied in the field of carbon fiber graphene plastic pipe, can solve the problems of poor tensile and bending resistance, low strength, poor quality, etc., achieve high performance quality, simple and easy operation, and eliminate heavy weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

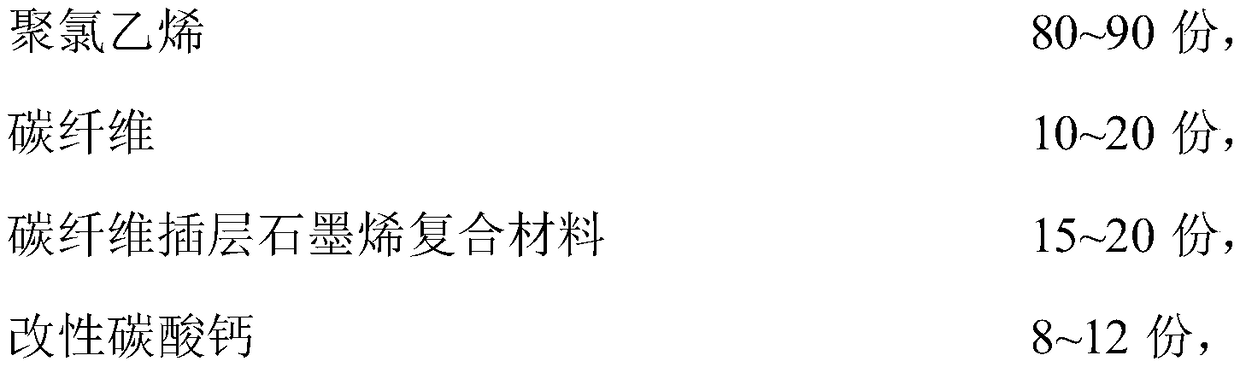

[0024] A light and high-strength carbon fiber graphene plastic tube, the light and high-strength carbon fiber graphene plastic tube is prepared from the raw materials of the following parts by weight:

[0025]

[0026] The light and high-strength carbon fiber graphene plastic pipe is prepared by the following method:

[0027] Step 1, preparation of carbon fibers: place cellulose nanofibers in a tube furnace, then pass through protective gas, raise the temperature to 300°C at a heating rate of 2°C / min and keep it for 1h, and then increase the temperature at a heating rate of 5°C / min Raise the temperature to 700°C and hold it for 2 hours, and finally lower the temperature to room temperature at a rate of 5°C / min to obtain carbon fibers;

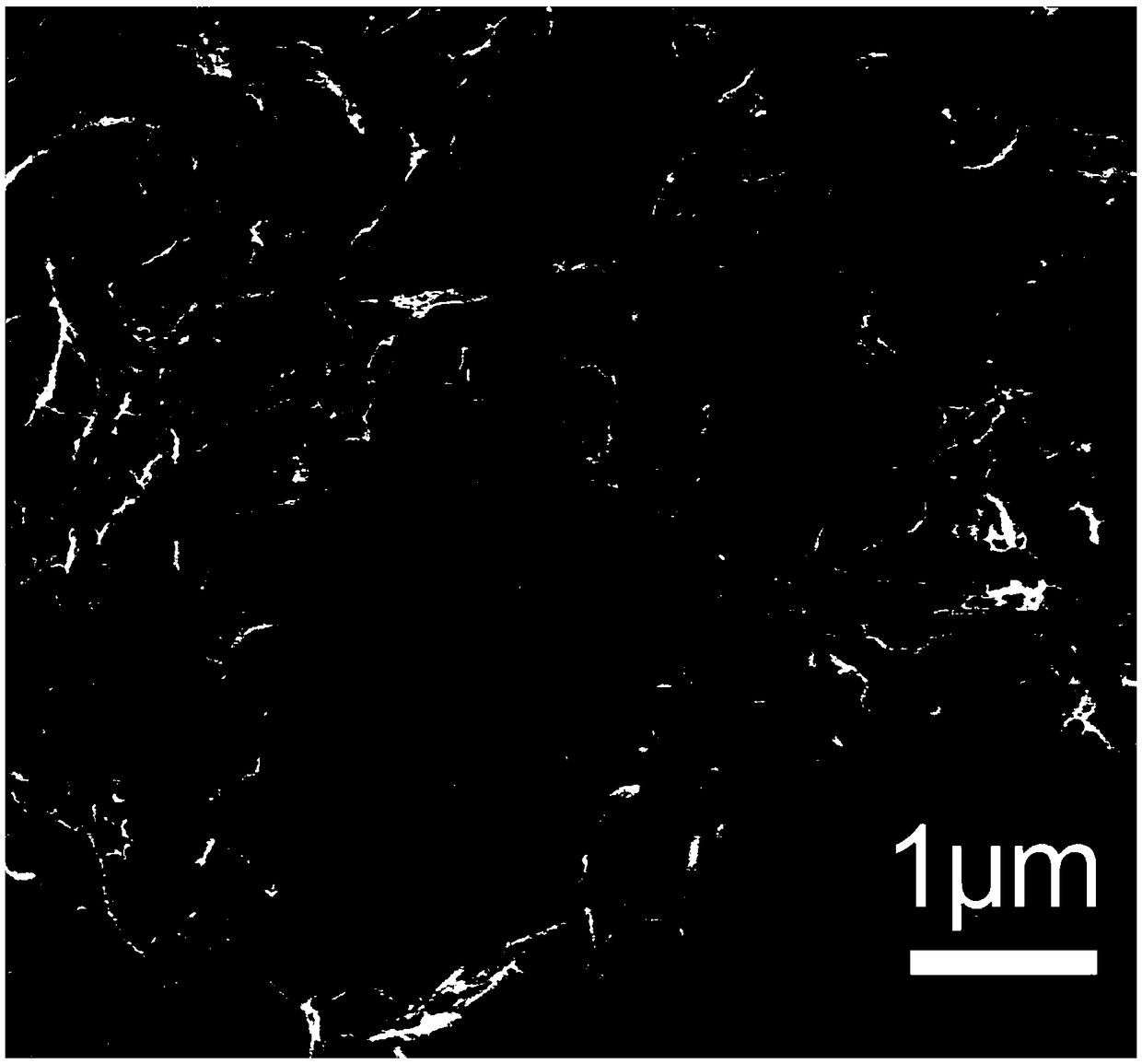

[0028] Step 2, preparation of carbon fiber intercalated graphene composite material: disperse cellulose nanofibers in an aqueous solution to prepare a 1wt% dispersion, and use an ultrasonic pulverizer with a power of 1200W to process the dis...

Embodiment 2

[0033] A light and high-strength carbon fiber graphene plastic tube, the light and high-strength carbon fiber graphene plastic tube is prepared from the raw materials of the following parts by weight:

[0034]

[0035]

[0036] The light and high-strength carbon fiber graphene plastic pipe is prepared by the following method:

[0037] Step 1, preparation of carbon fibers: place cellulose nanofibers in a tube furnace, then pass through protective gas, raise the temperature to 500°C at a heating rate of 5°C / min and keep it for 1h, and then increase the temperature at a heating rate of 10°C / min Raise the temperature to 1000°C and hold it for 0.5h, and finally lower the temperature to room temperature at a rate of 10°C / min to obtain carbon fibers;

[0038]Step 2, preparation of carbon fiber intercalated graphene composite material: disperse cellulose nanofibers in an aqueous solution to prepare a 1wt% dispersion, and use an ultrasonic pulverizer with a power of 1500W to proc...

Embodiment 3

[0043] A light and high-strength carbon fiber graphene plastic tube, the light and high-strength carbon fiber graphene plastic tube is prepared from the raw materials of the following parts by weight:

[0044]

[0045] The light and high-strength carbon fiber graphene plastic pipe is prepared by the following method:

[0046] Step 1, preparation of carbon fibers: place cellulose nanofibers in a tube furnace, then pass through protective gas, raise the temperature to 400°C at a heating rate of 5°C / min and keep it for 2 hours, and then heat at a heating rate of 10°C / min Raise the temperature to 800°C and hold it for 1 hour, and finally lower the temperature to room temperature at a rate of 10°C / min to obtain carbon fibers;

[0047] Step 2, preparation of carbon fiber intercalated graphene composite material: dispersing cellulose nanofibers in an aqueous solution to prepare a 1wt% dispersion, and using an ultrasonic pulverizer with a power of 1400W to process the dispersion fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com