Wind power generation system

A technology of wind power generation system and generator, which is applied in the direction of wind power generator, wind power motor combination, wind power generator at right angles to the wind direction, etc. It can solve the problems of low wind speed at start-up, large number of friction pairs and complex overall structure of wind energy utilization rate, etc. Achieve the effects of improving wind energy utilization, high stability, and reducing rotation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

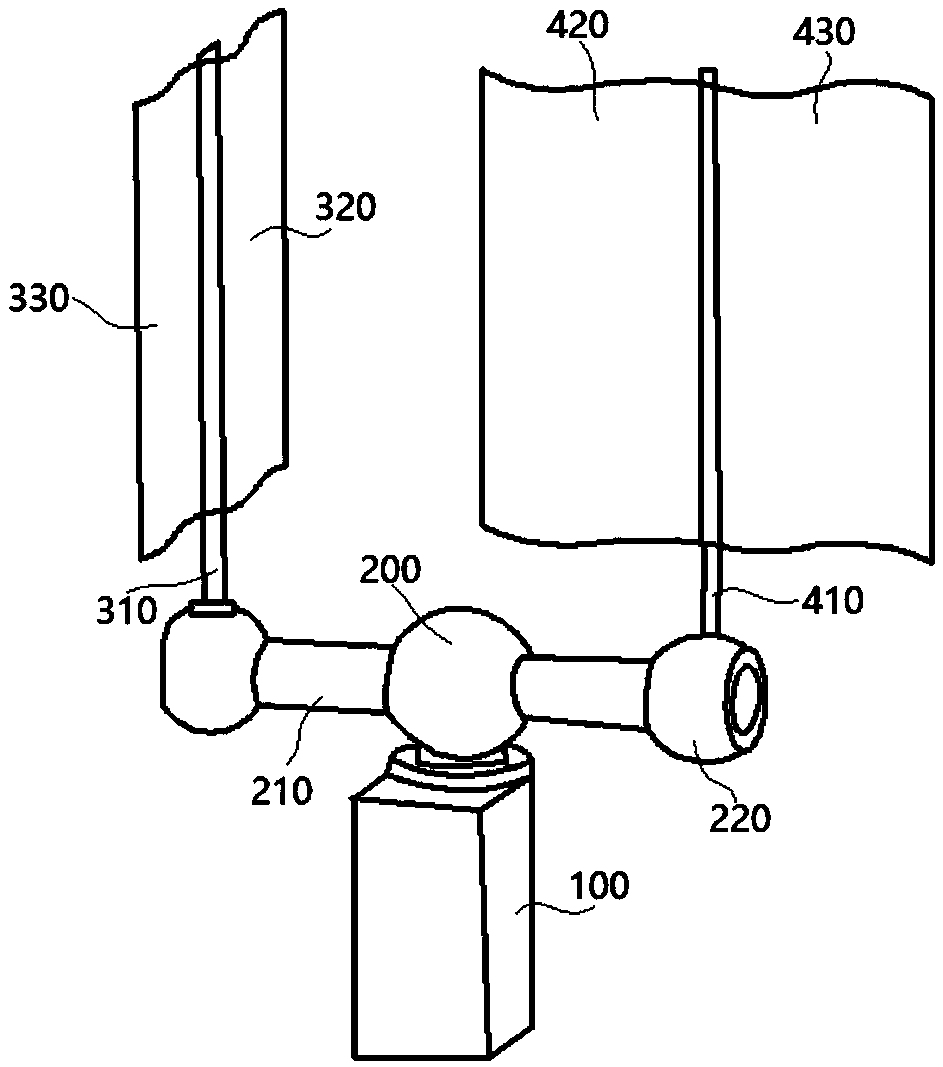

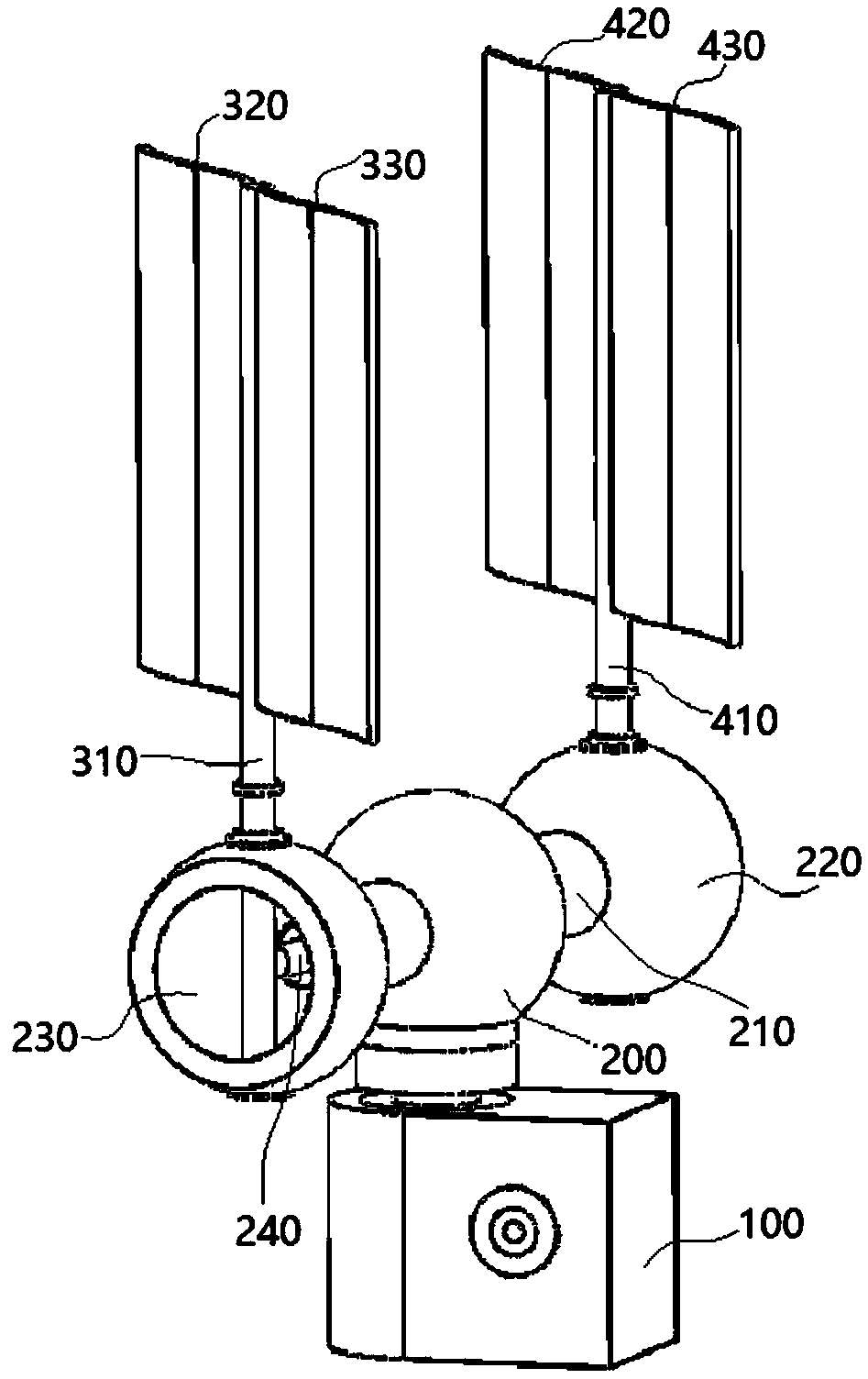

[0046] Such as Figure 1-Figure 11 As shown, a wind power generation system in this embodiment includes a frame 100, a generator unit and blades, a generator unit is arranged on one side of the frame 100, and the frame 100 and the generator unit are driven by a helical gear ; The top of the frame 100 is provided with a transmission box 200, both sides above the transmission box 200 are provided with blades, the blades and the transmission box 200 are driven by bevel gears, and the blades on each side include two S-shaped blades that are symmetrically distributed in the center. Blades, double-blade design transmits greater torque and improves wind energy utilization. Specifically, the blade structure in this embodiment forms a wind turbine, and the wind turbine is designed using the principle of a half-rotation mechanism, that is, the blade rotates half a revolution itself while the transmission device (transmission box 200) revolves one revolution. The blades cross the path o...

Embodiment 2

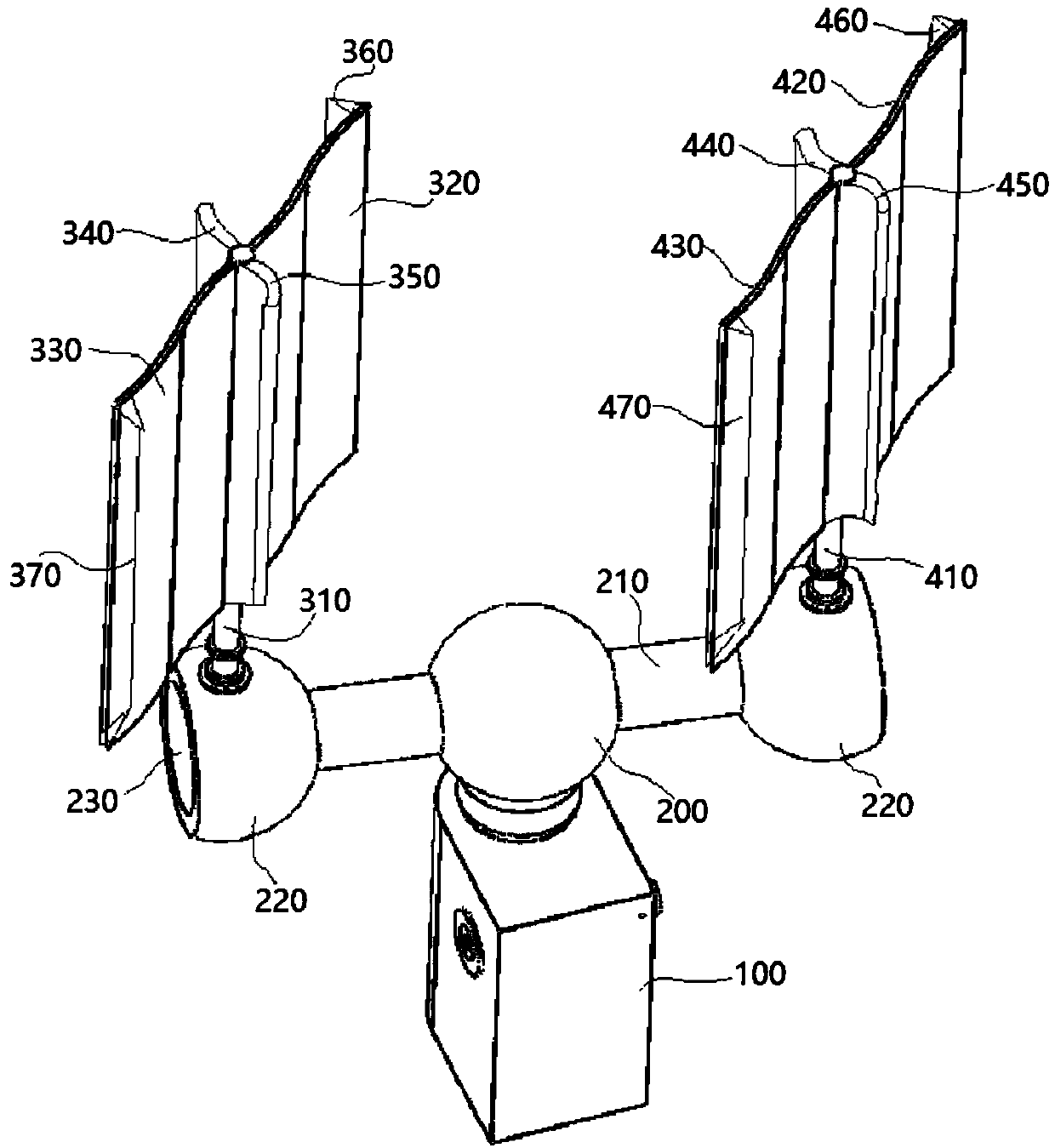

[0065] A wind power generation system in this embodiment has the same basic structure as in Embodiment 1. Furthermore, the blades in this embodiment also include auxiliary blades. Specifically, first auxiliary blades 340 and second auxiliary blades are arranged on both sides of the first vertical shaft 310. The second sub-blade 350, the first sub-blade 340 and the second sub-blade 350 are all arc-shaped blades and both form a centrally symmetrical S-shaped structure on both sides of the first vertical shaft 310, and the arc-shaped concave direction of the first sub-blade 340 is in line with the The arc-shaped concave section of the first blade 320 close to the first vertical shaft 310 is oppositely arranged, and the arc-shaped concave section of the second auxiliary blade 350 is arranged opposite to the arc-shaped concave section of the second blade 330 close to the first vertical shaft 310, that is, as shown in FIG. 2 As shown in the azimuth, the arc section of the S-shaped bl...

Embodiment 3

[0069] A wind power generation system in this embodiment has the same basic structure as that in Embodiment 2. Furthermore, the blades in this embodiment also include cutting blades. Specifically, the side of the first blade 320 away from the first vertical shaft 310 is arranged along the height direction. There is a first cutting blade 360, and the side of the second blade 330 away from the first vertical shaft 310 is provided with a second cutting blade 370 along the height direction. A secondary blade 340 shrinks relatively inwardly, and the thickness of the first cutting blade 360 gradually decreases along the direction away from the first blade 320, and the top end of the first cutting blade 360 extends obliquely downward along the direction away from the first blade 320, the first The bottom end of the cutting blade 360 extends upwardly in a direction away from the first blade 320; similarly, the second cutting blade 370 extends obliquely in a direction close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com