An external independent air-cooling device and cooling operation method for bearings in thermal environment conditions

A technology of air cooling device and operation method, which is applied in the direction of bearing cooling, bearing, shaft and bearing, etc., to facilitate observation and judgment, and to avoid blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further illustrated by the following examples, but not limited to the following examples.

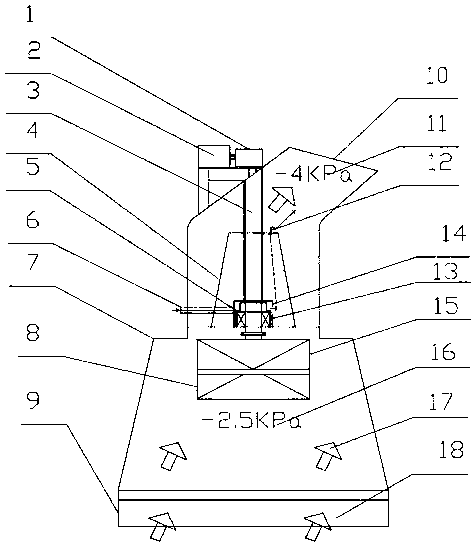

[0025] like figure 1 As shown, the original design structure is that the negative pressure in the vertical mill sucks cold air into the mill. In order to protect the lower bearing 5 of the powder separator, the vertical mill manufacturer designed a vertical shaft shield 4 at the lower bearing 5 of the powder separator to facilitate personnel. Carry out equipment maintenance work in a dust-free state. In the original design, the cold air outside the mill enters the vertical shaft protective cover 4 through the air inlet pipe 6, and then enters the upper pipe of the vertical mill outlet through the air outlet 12 of the protective cover, which plays a role in supplying the bearings. Cooling effect, see the specific process figure 1 shown.

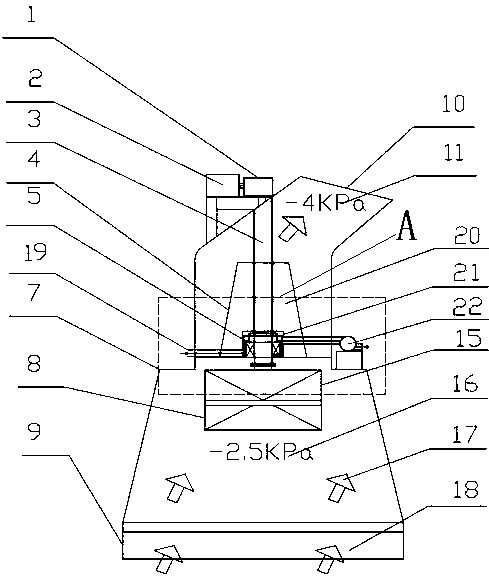

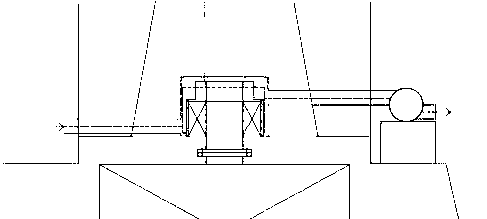

[0026] The present invention improves the position of the bearing cooling air duct. A second air inlet duct 19 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com