Integrated fixed bed chemical looping combustion device

A technology of chemical looping combustion and fixed bed, which is applied to gas fuel burners, burners, combustion methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The integrated fixed bed chemical looping combustion device works as follows:

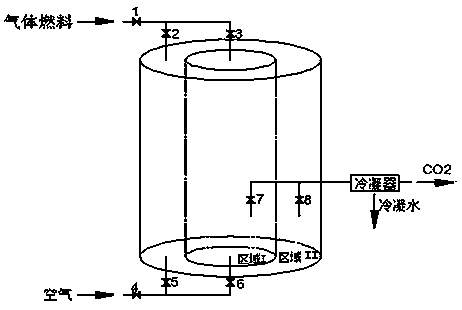

[0014] The present invention has designed a set of integrated chemical looping combustion device, and its specific structure is as follows figure 1 As shown, its structure will be described in detail below.

[0015] The device is composed of three parts, namely tank part, pipeline part, solenoid valve part controlled by PLC, combustion product and waste gas collection part. The tank part is a sleeve structure, consisting of two cylinders, the inner cylinder can be used as an air reactor (fuel reactor), and the space between the outer cylinder and the inner cylinder wall can be used as a fuel reactor (air reactor) ), the wall of the inner cylinder is perforated, and the perforated part is provided with a solenoid valve switch.

[0016] The pipeline part is composed of a pipeline and a solenoid valve. One side of the pipeline is connected to the tank body, and the other side of the pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com