Partially reinforced composite material bulletproof helmet

A technology of composite materials and bulletproof helmets, which is applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of instability of the back convex height side wall, unstable performance of the back convex height side wall, and unbalanced pressure, etc., to achieve Protects from damage, prevents penetration, and ensures the height of back convex deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

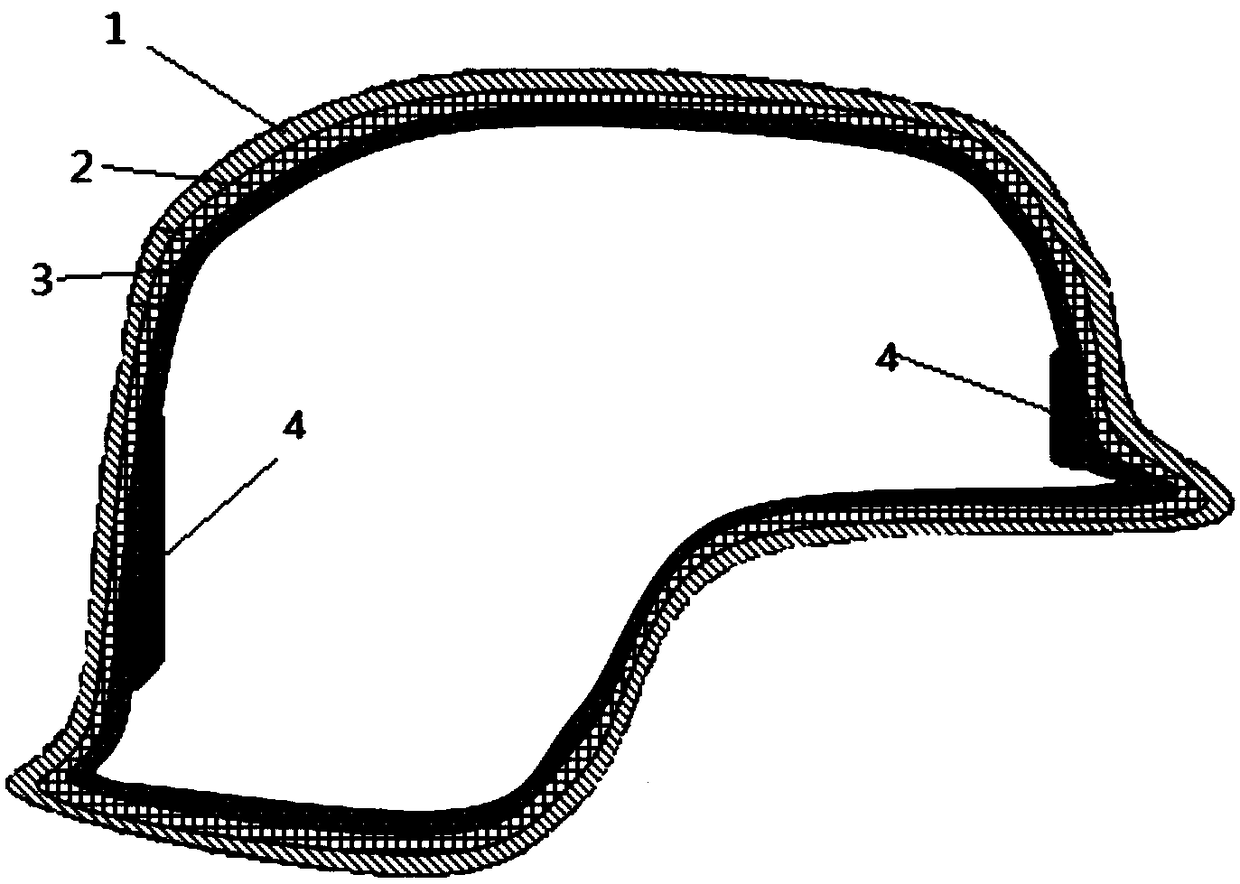

[0033] Such as figure 1As shown, a kind of locally strengthened composite material bulletproof helmet includes from outside to inside: outer bulletproof layer 1, middle buffer layer 2, internal rigid reinforcement layer 3, internal rigid reinforcement layer 4 thickened on the forehead and back of the head, so The interface layers of the outer bulletproof layer 1, the middle buffer layer 2, the inner rigid reinforcement layer 3, and the inner rigid reinforcement layer 4 thickened on the forehead and the back of the head are bonded and formed by acrylic resin, and the bonding temperature is below 50°C. The bonding time is 1 hour, and the bonding pressure is -0.08MPa; the internal rigid reinforcement layer adopts the form of unequal thickness, that is, the thickness of the forehead and the back of the head of the bulletproof helmet is greater than that of other parts.

[0034] The outer bulletproof layer 1 is a unidirectional arrangement of UHMWPE fibers reinforced by water-based...

Embodiment 2

[0038] Such as figure 1 As shown, a kind of locally strengthened composite material bulletproof helmet includes from outside to inside: outer bulletproof layer 1, middle buffer layer 2, internal rigid reinforcement layer 3, internal rigid reinforcement layer 4 thickened on the forehead and back of the head, so The interface layers of the outer bulletproof layer 1, the middle buffer layer 2, the inner rigid reinforcement layer 3, and the inner rigid reinforcement layer 4 thickened on the forehead and the back of the head are bonded and molded by phenolic resin, and the bonding temperature is below 50°C. The bonding time is 0.5 hours, and the bonding pressure is -0.09MPa; the internal rigid reinforcement layer adopts the form of unequal thickness, that is, the thickness of the forehead and the back of the head of the bulletproof helmet is greater than that of other parts.

[0039] The outer bulletproof layer 1 is a pre-impregnated fabric reinforced with acrylic-vinyl copolymer r...

Embodiment 3

[0043] Such as figure 1 As shown, a kind of locally strengthened composite material bulletproof helmet includes from outside to inside: outer bulletproof layer 1, middle buffer layer 2, internal rigid reinforcement layer 3, internal rigid reinforcement layer 4 thickened on the forehead and back of the head, so The interface layers of the outer bulletproof layer 1, the middle buffer layer 2, the inner rigid reinforcement layer 3, and the inner rigid reinforcement layer 4 thickened on the forehead and the back of the head are bonded and formed by acrylic resin, and the bonding temperature is below 50°C. The bonding time is 1 hour, and the bonding pressure is -0.1 MPa; the internal rigid reinforcement layer adopts the form of unequal thickness, that is, the thickness of the forehead and the back of the head of the bulletproof helmet is greater than that of other parts.

[0044] The outer bulletproof layer 1 is a fabric made of PBO fiber plain weave reinforced polyethylene resin e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com