Measurement method of magnetic levitation thermobalance based on photothermal rapid temperature rise

A measurement method and magnetic levitation technology, applied in the direction of weighing by removing a certain component, can solve the problems of slow heating rate, complex equipment structure, affecting measurement accuracy, etc., and achieve the effect of precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

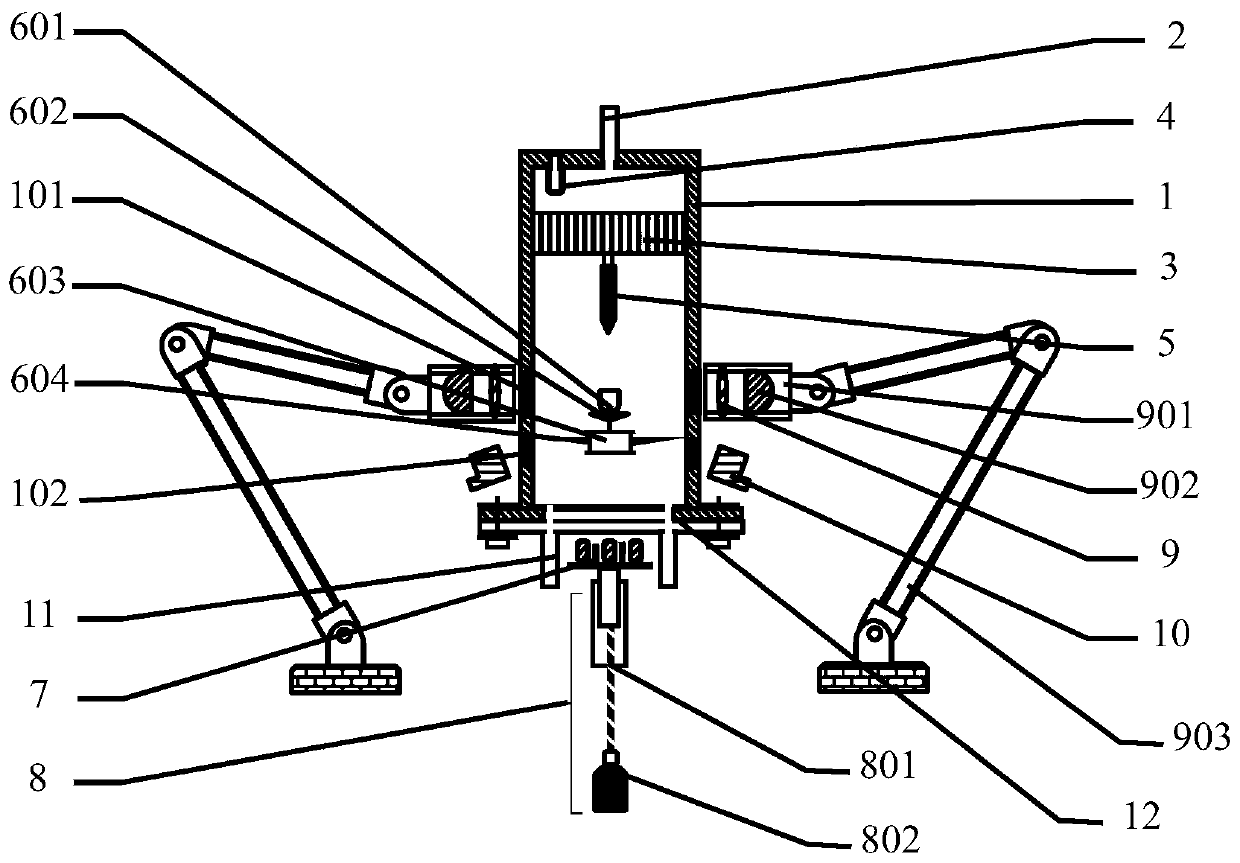

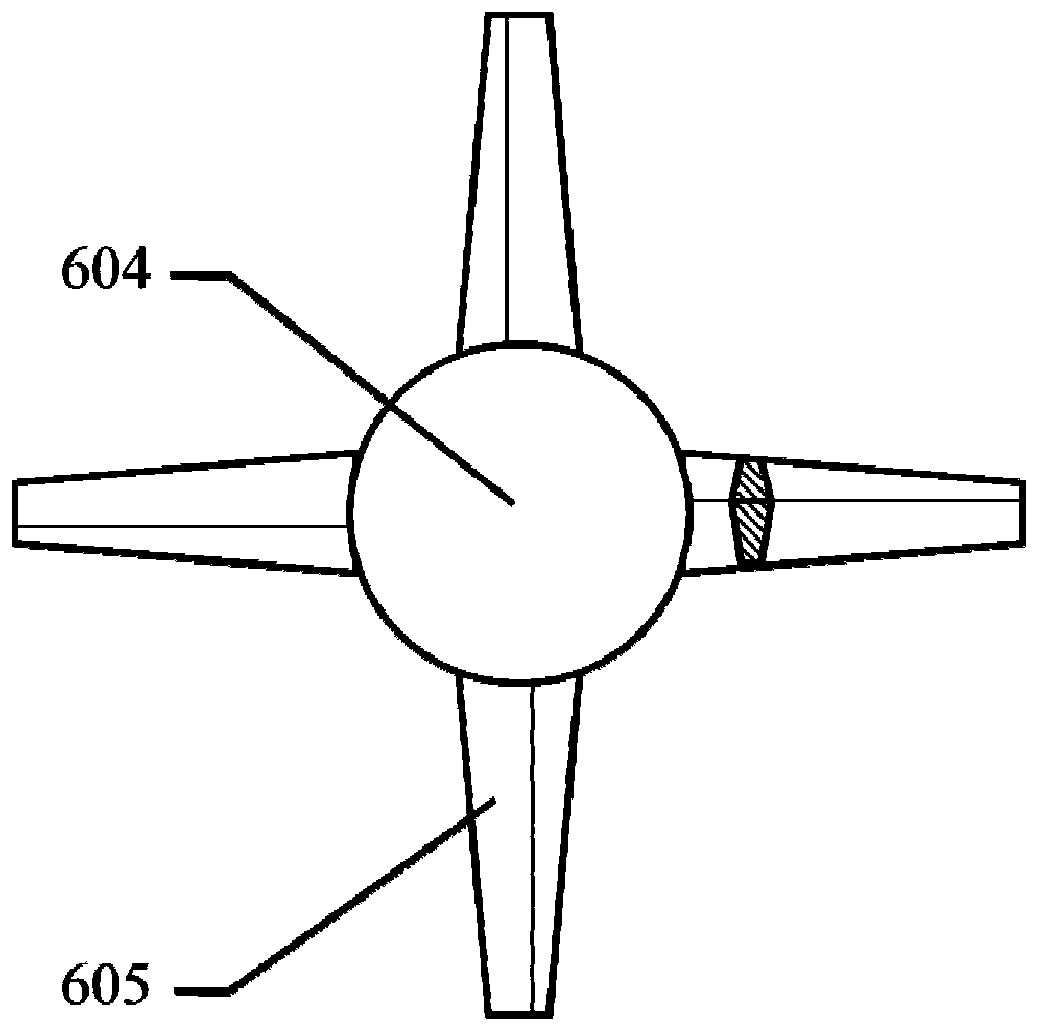

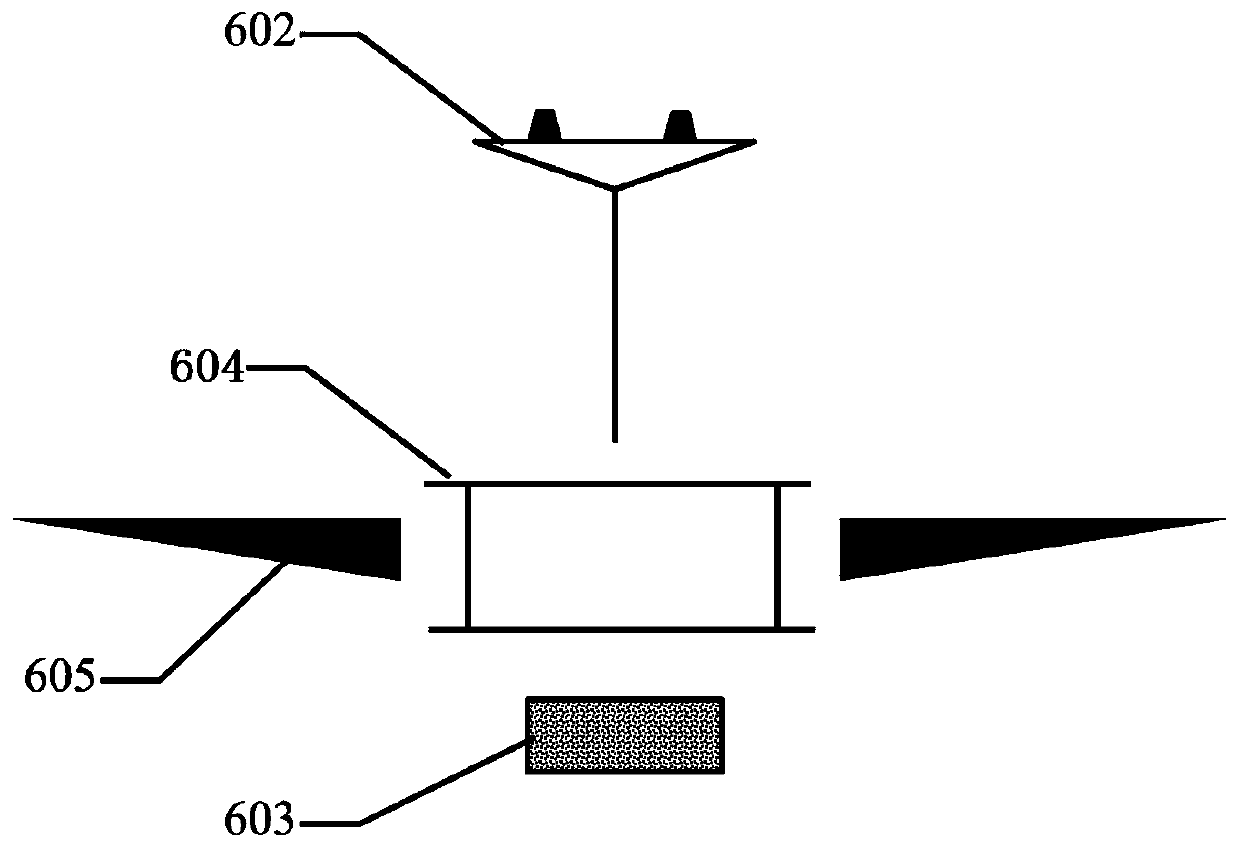

[0057] Such as Figure 1~5 As shown, this embodiment discloses a magnetic levitation thermal balance based on photothermal rapid temperature rise specially designed for realizing the method of the present invention, which includes a closed container 1, a reaction pool 601, a magnetic levitation device, a stator lifting assembly 8, and a laser displacement monitoring Component 10, photothermal heating component 9 and photothermal heating component displacement device 903, wherein:

[0058] The airtight container 1 is cylindrical, with a gas inlet 2 at the center of the top end, and a detachable cover plate 12 (fixed by bolts) at the lower end. Two gas outlets 11 are symmetrically arranged on the cover plate 12. The airtight container 1 The interior is provided with a pressure monitoring component 4, an airflow stabilizing device 3, and an infrared temperature measuring component 5, and the side wall is provided with a displacement monitoring window 102 made of a transparent mat...

Embodiment 2

[0066] This embodiment discloses a method for measuring the quality change of materials under temperature control conditions using the magnetic levitation thermobalance in Embodiment 1, and the steps are as follows:

[0067] 1) Weigh the mass as g 0 The measured materials are sent to the reaction pool 601;

[0068] 2) Remove the cover plate 12, place the reaction pool 601 on the support frame 602 of the magnetic levitation float 603, then place the magnetic levitation float 603 on the center of the cover plate 12, install the cover plate 12 on the airtight container 1, and adjust the magnetic levitation stator 7 The position makes it be located directly below the center of the rear cover plate 12 after installation;

[0069] 3) Start the magnetic levitation device, and after the magnetic field is stable, move the magnetic levitation stator 7 upwards, so that the magnetic levitation float 603 is suspended in the airtight container 1;

[0070] 4) Continuously feed the gas need...

Embodiment 3

[0084] This embodiment discloses the method for establishing a database using multiple groups of controlled experiments, and the specific steps are as follows:

[0085] 1) Determine the mass range of the thermobalance according to the needs of the experiment. Within this range, select the initial mass g at equidistant distances 0 , recorded as g from the minimum value to the maximum value 01 ,..., g 0i ,..., g 0m , i is an integer, and 1<i<m;

[0086] 2) Determine the range of gas flow velocity according to the needs of the experiment. Within this range, select the calibration flow velocity v equidistantly, and record it as v in sequence from the minimum value to the maximum value 1 ,...,v j ,...,v n , j is an integer, and 1<j<n;

[0087] 3) Take a set of v j , g 0i , use another analytical balance to weigh the mass as g 0i The measured material is put into the reaction tank, and then the reaction tank is placed in the thermal balance, and the magnetic levitation floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com