Micropressure permeameter, and test method thereof

A test method and technology of permeameters, which are applied in the field of permeameters, can solve the problems of difficult accurate measurement of flow rates and slow water flow in low-permeability media, and achieve the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

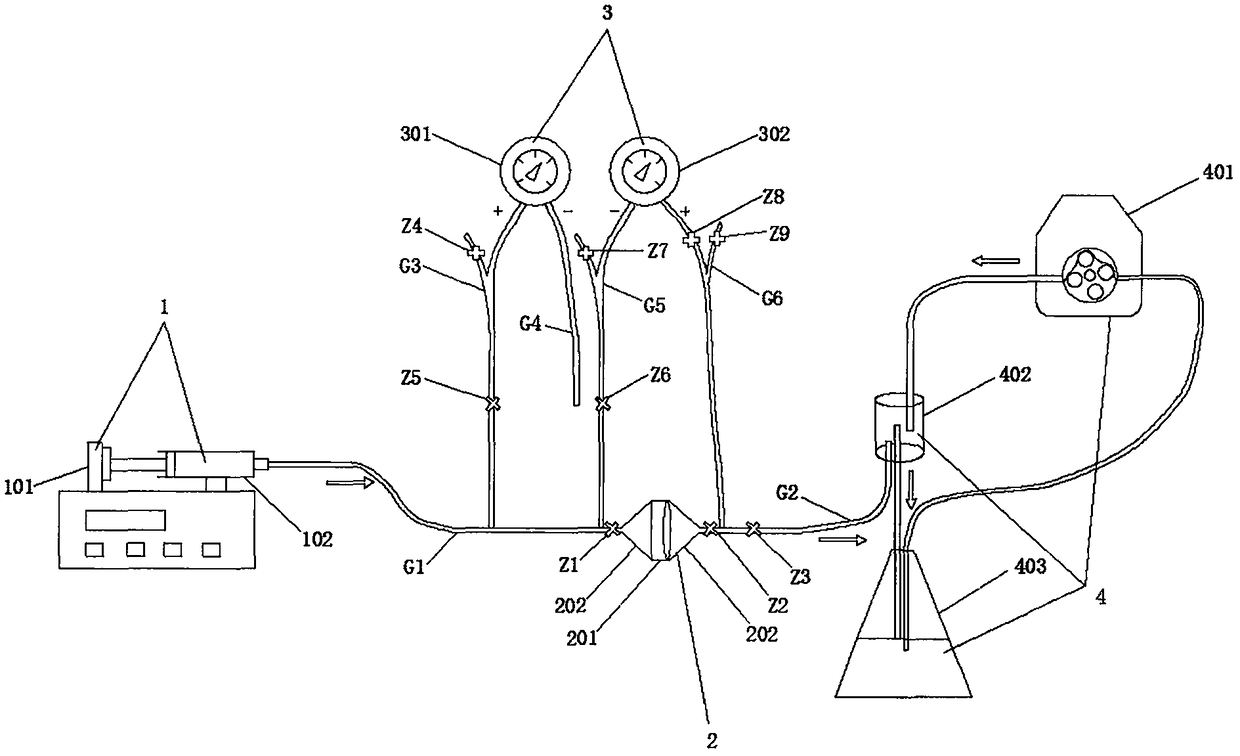

Method used

Image

Examples

preparation example Construction

[0018] Step 1. Preparation of the sample. If it is the undisturbed soil, first use a utility knife to trim it into a cylindrical soil sample slightly higher than the ring knife, then press the special ring knife 201 into the soil sample, use the utility knife to flatten the top, and cover it Funnel-type sand core 202; then turn the soil sample together with the funnel-type sand core 202 vertically 180 degrees, continue to use a utility knife to flatten the other side of the ring knife, cover another funnel-type sand core 202, and finally fix the funnel with two duckbill clips Around the sand core 202, if it is remolding soil, first place the special ring knife 201 on the funnel-type sand core 202, fill the remolding soil to the top of the special ring knife 201, and cover another funnel-type sand core 202, Finally, use a duckbill clip to fix the surroundings of the funnel-type sand core;

[0019] Step 2. The sample is saturated with water. Inject a certain amount of liquid, pu...

Embodiment

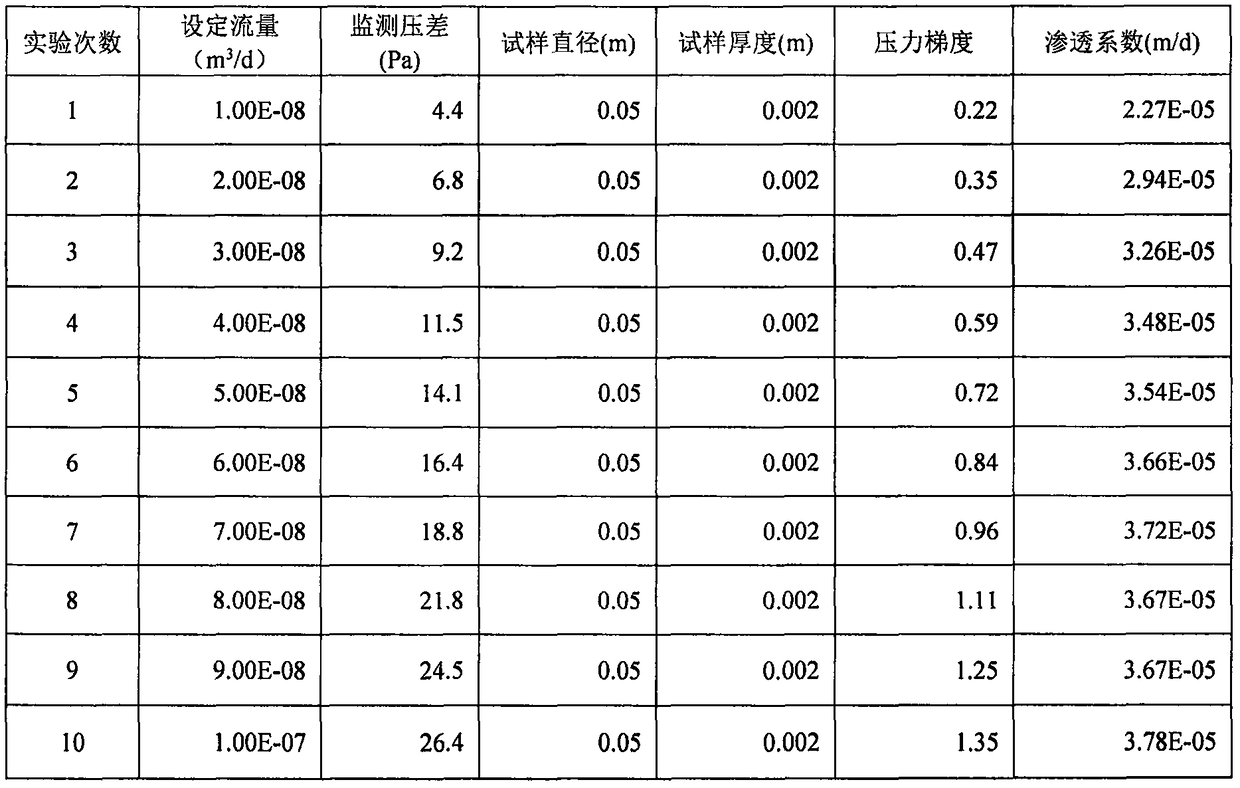

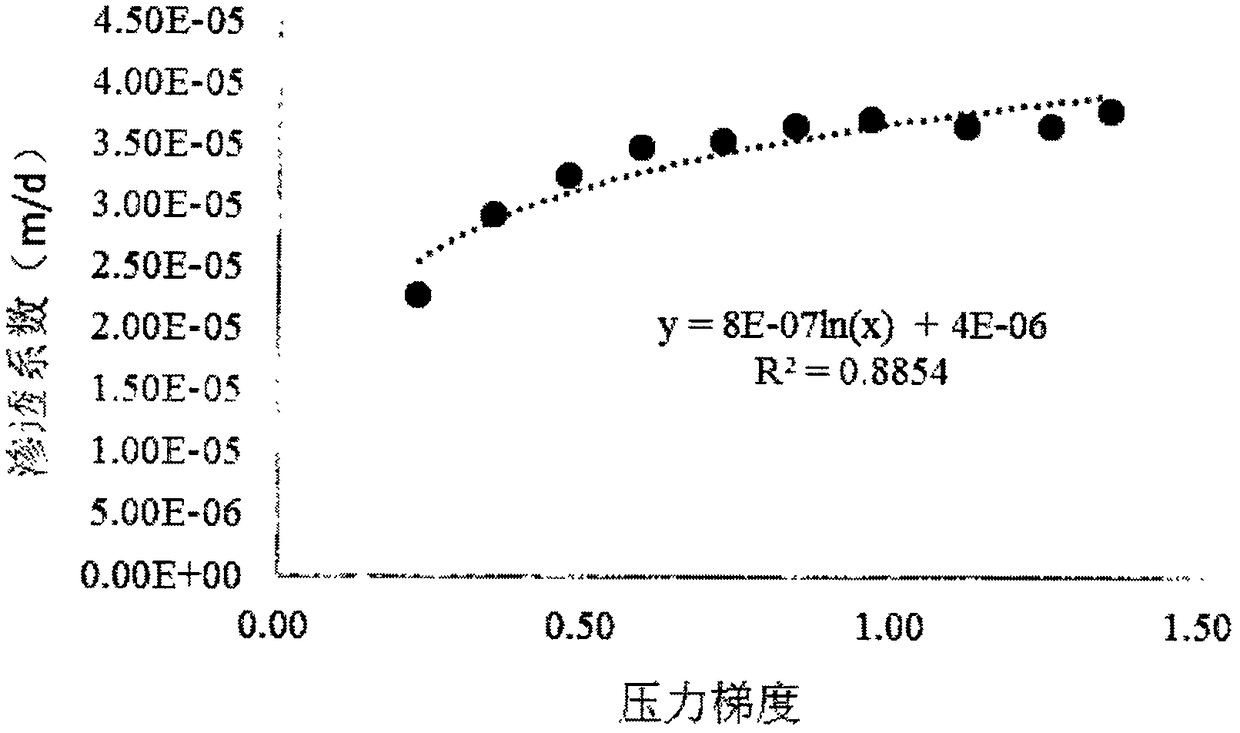

[0033] Embodiment: The test process of the undisturbed soil and the remolded soil is exactly the same, but the sample preparation process is slightly different. The test data of an undisturbed soil is used to illustrate how to realize the calculation of permeability coefficient and the establishment of mathematical equations. Prepare samples according to step 1; saturate the sample according to step 2; adjust the water level at the water inlet and outlet according to step 3. According to step four, to figure 2 The flow rate set in the first experiment is 1.00E-08m 3 / d Inject fluid. According to step 5, monitor the value change of the differential pressure gauge. After the value is stable, record the reading of the second differential pressure gauge to figure 2 (4.4Pa), according to figure 2 Repeat step 4 and step 5 10 times at the flow rate set in , and record the pressure difference after each experiment stabilizes at the same time. After the 10 experiments are compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com