Flexible electromagnetic ultrasonic guided wave sensor for tube, and detection method thereof

An electromagnetic ultrasonic and sensor technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and instruments. It can solve the problems of large probe volume, complicated installation, and high installation surface requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

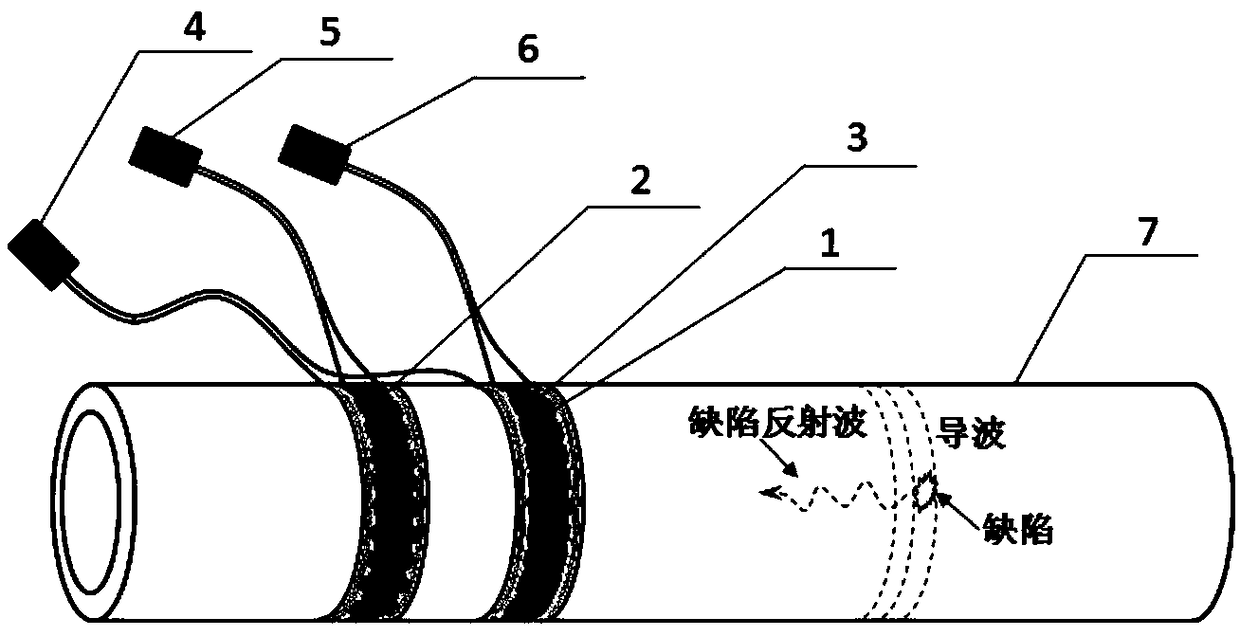

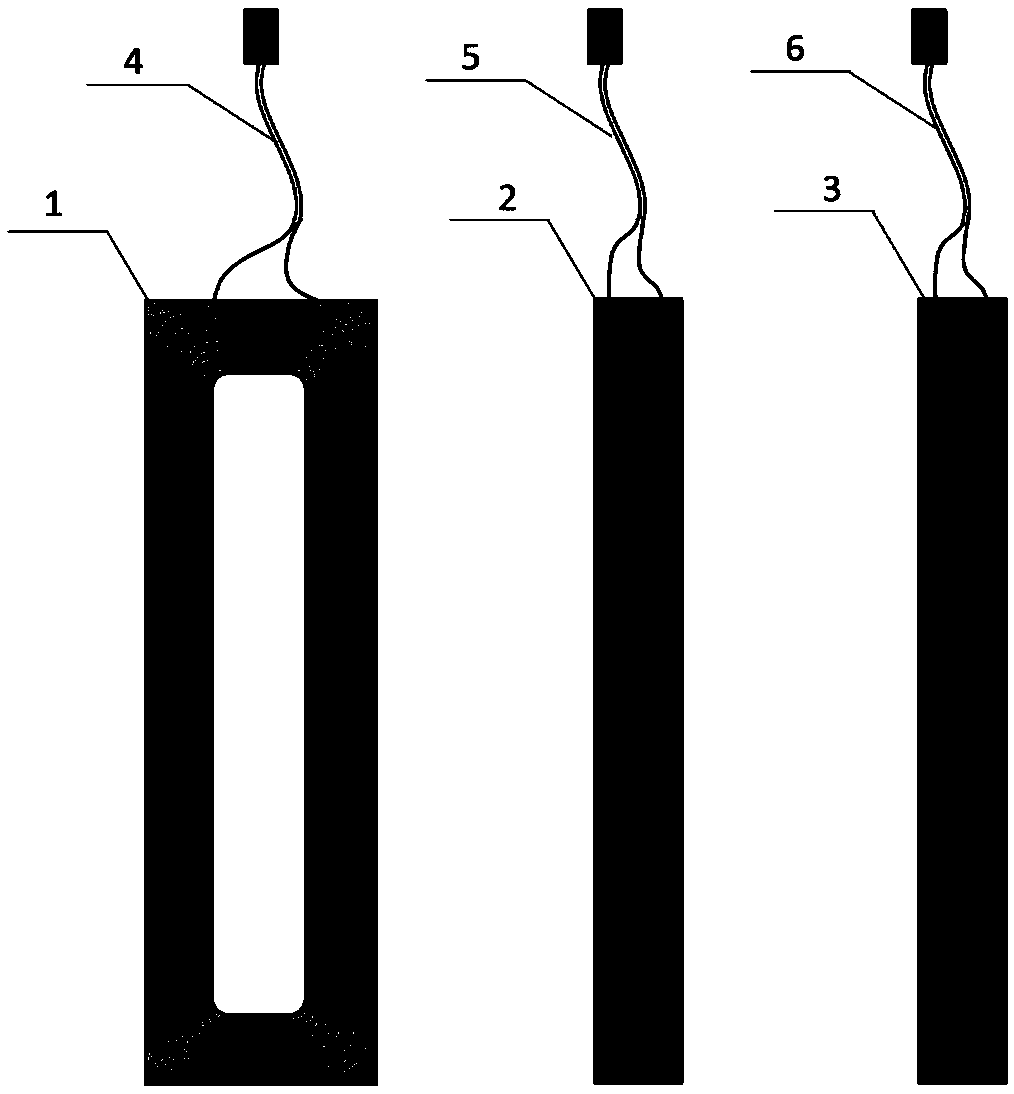

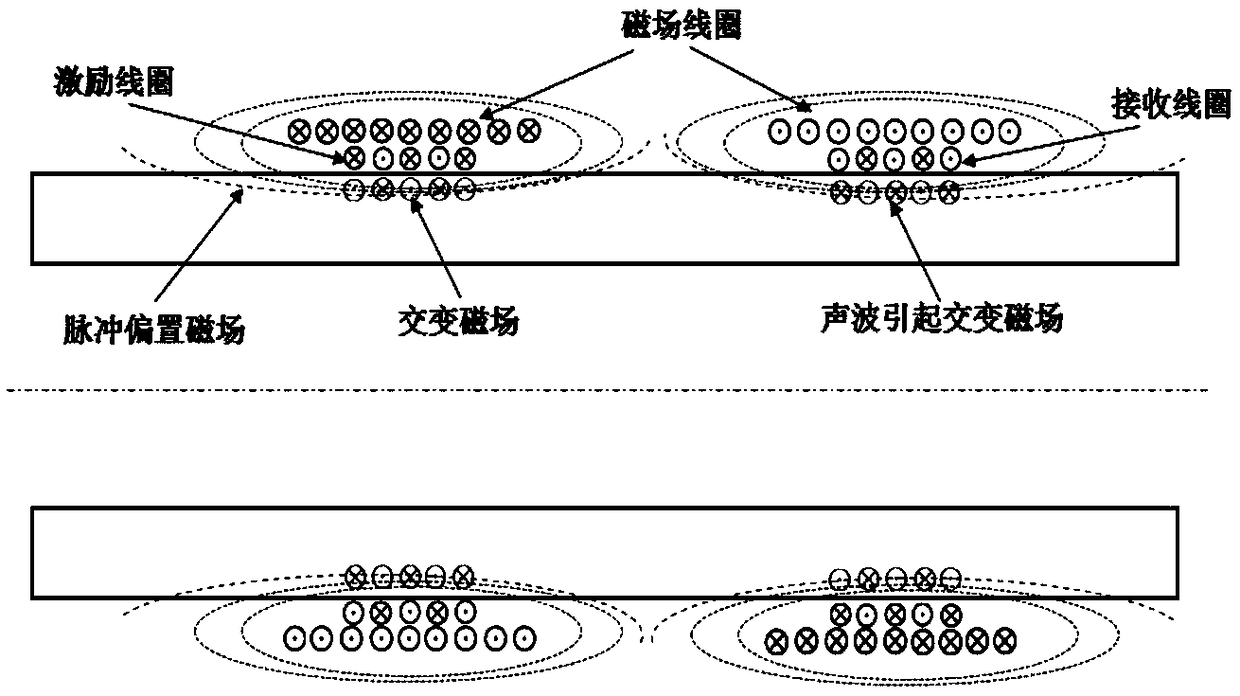

[0019] Such as figure 1 and figure 2 As shown, the flexible electromagnetic ultrasonic guided wave sensor of the present invention is composed of a pulse bias magnetic field coil 1, an electromagnetic ultrasonic excitation coil 2, an electromagnetic ultrasonic receiving coil 3, a flexible protective layer and three shielding wires 4, 5, 6; The ultrasonic excitation coil 2 and the electromagnetic ultrasonic receiving coil 3 are pasted directly below the two sides of the pulse bias magnetic field coil 1 respectively, and each of the three coils is connected to a shielded wire, and the other end of the shielded wire is connected to a two-core plug.

[0020] Such as figure 2 As shown, the pulse bias magnetic field coil 1 of the flexible electromagnetic ultrasonic guided wave sensor used in the present invention is a planar racetrack c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com