A method for reducing the photomask fog surface defects through humidity modification

A mask and matte technology, applied in the field of microelectronics, can solve the problems of repeated defects, high incidence of fog-like defects, easy breeding of haze, etc., and achieve the effect of ensuring equipment accuracy and improving growth conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the following technical solutions and technical features can be combined with each other.

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

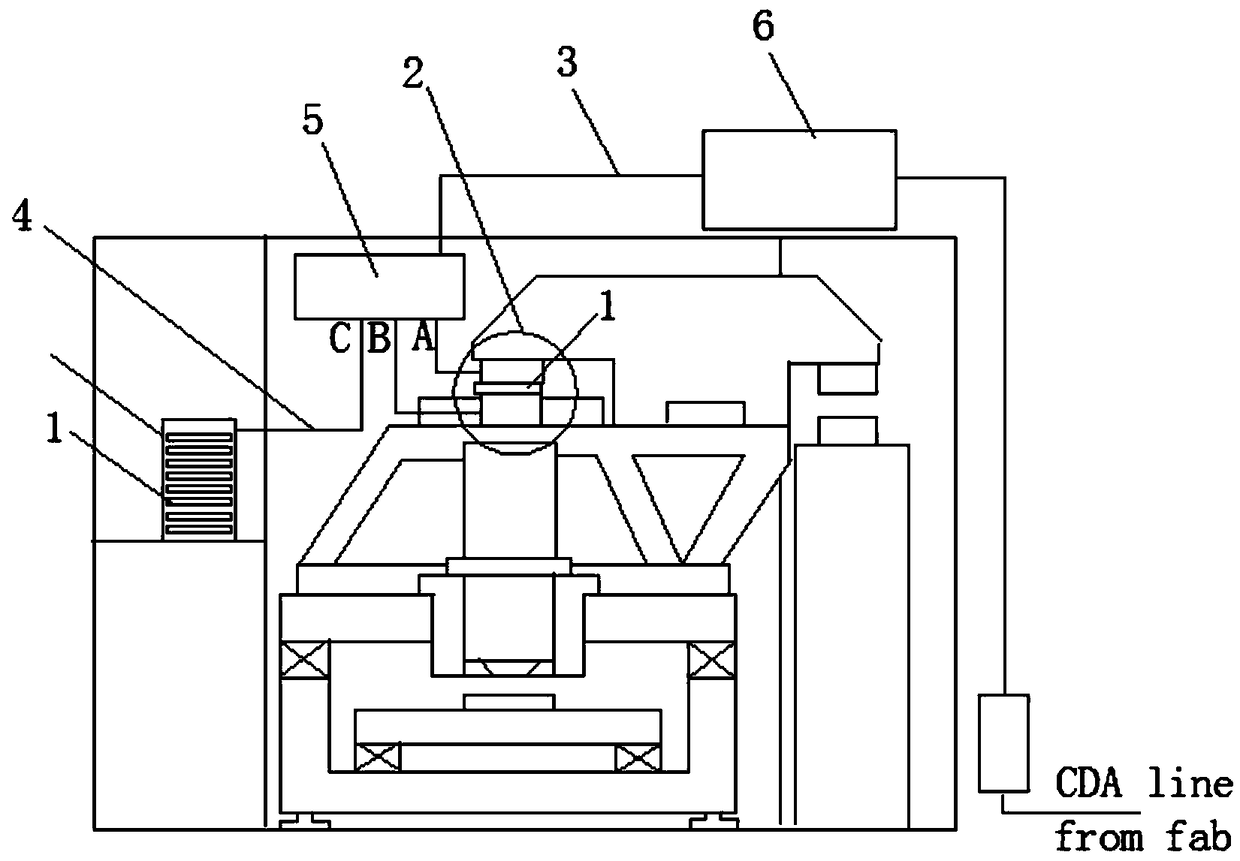

[0026] Such as figure 1 As shown, a method for reducing the fog surface defect of photomask 1 through humidity transformation is applicable to ArF excimer laser equipment for performing the exposure process of photomask 1, and the above-mentioned ArF excimer laser equipment includes a mask for performing the above-mentioned exposure process stage and a gas pipeline 3 for delivering compressed dry air (Compressed dry air, CDA) to the above-mentioned mask stage 2 during the above-mentioned exposure process, the above-mentioned method includes:

[0027] Above-mentioned ArF excimer laser equipment is positioned at above-mentioned mask stage 2 ( figure 1 The area enclosed by the middle circle is the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com