Polycrystalline diamond compact surface defect classification and recognition method

A polycrystalline diamond, defect classification technology, applied in character and pattern recognition, image analysis, image data processing and other directions, can solve the problems of low detection accuracy, large human eye damage, low efficiency, etc., to achieve high classification and recognition rate, good quality. The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention is specifically described below in conjunction with accompanying drawing:

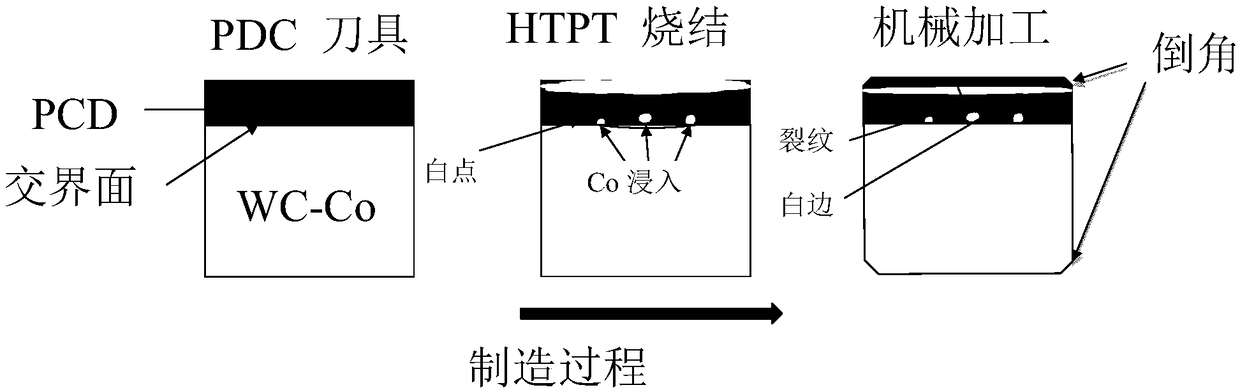

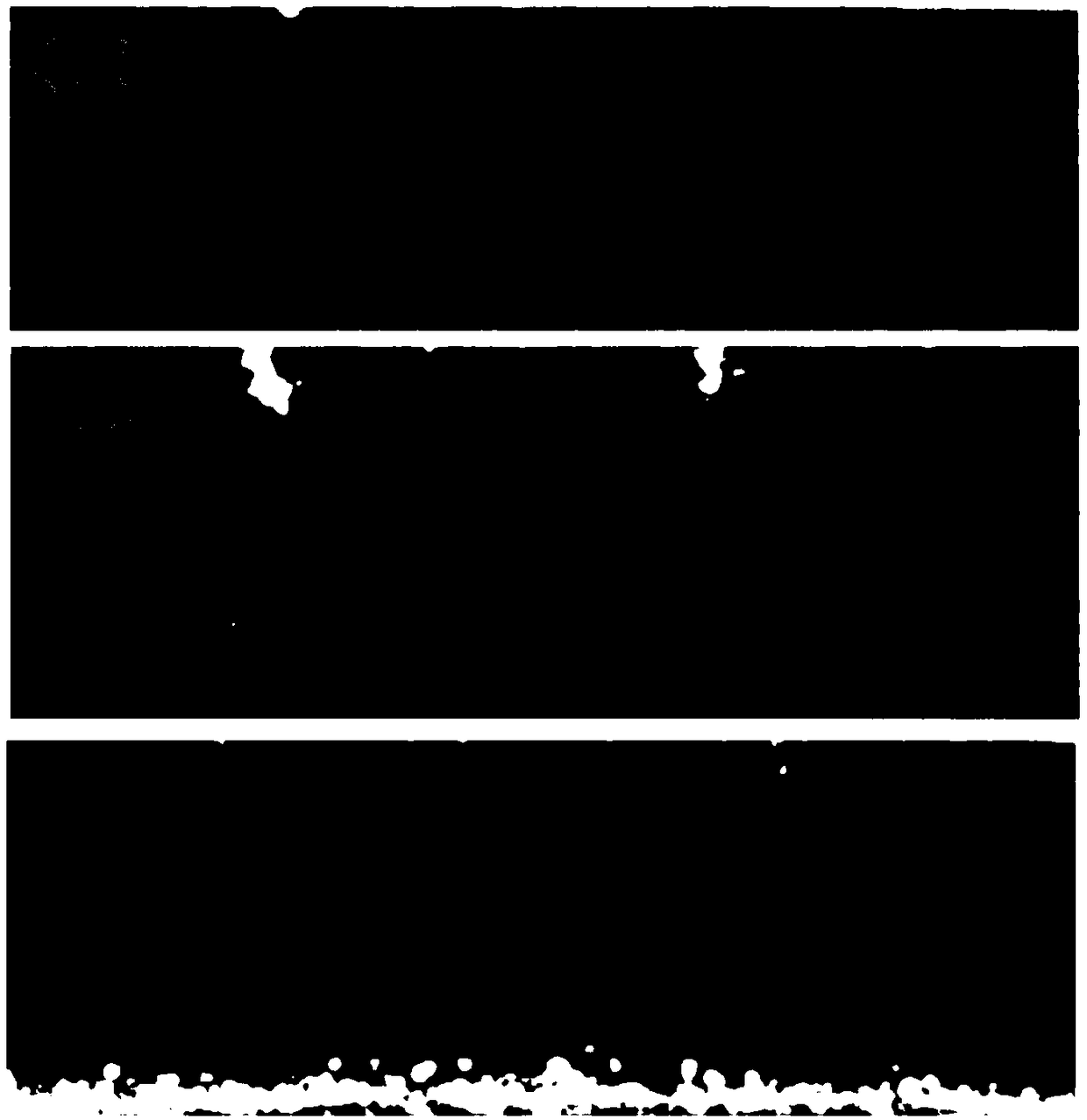

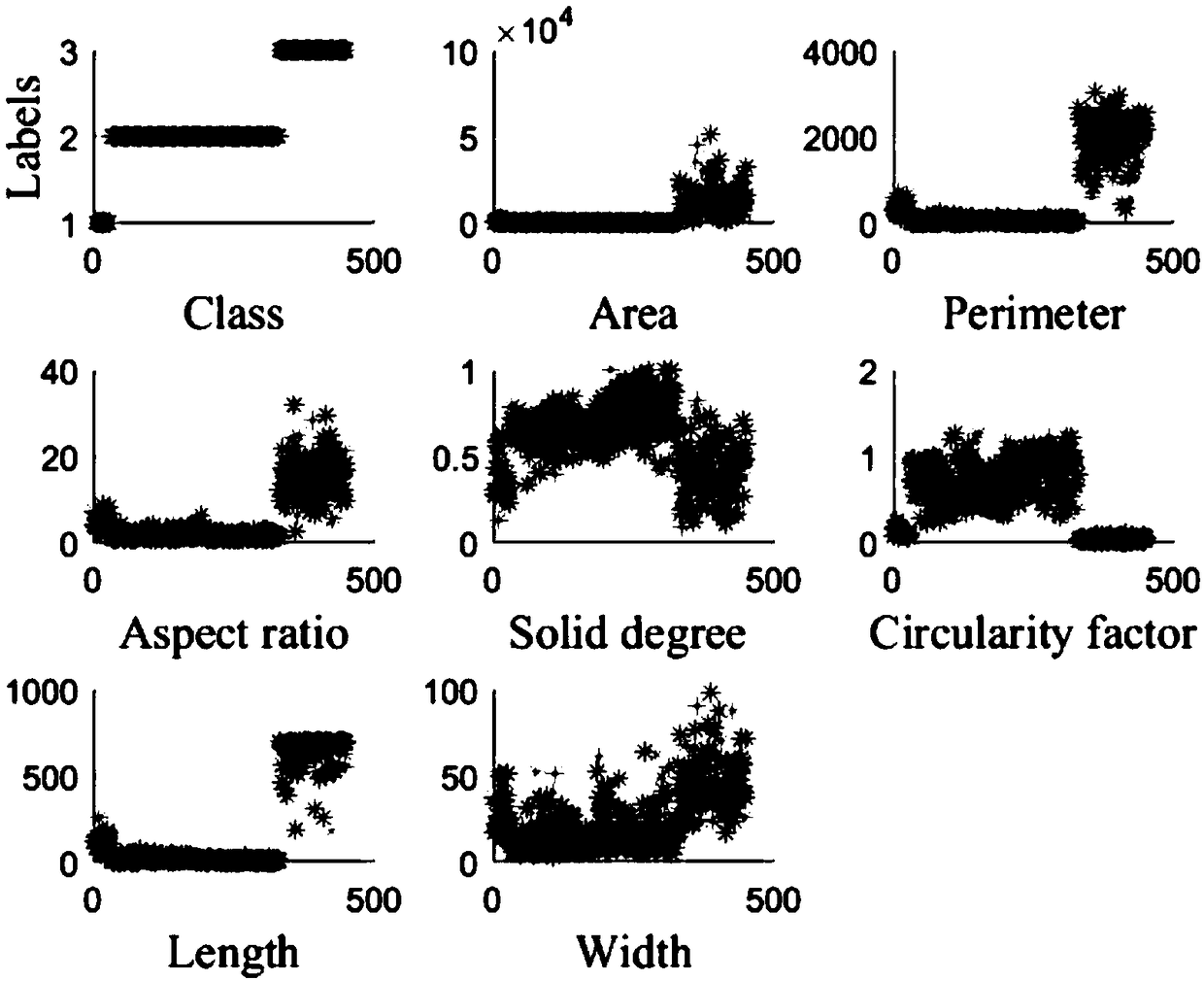

[0026] During the production and processing of polycrystalline diamond composite sheets, the common surface defects mainly include white spots, cracks and white edges, etc., but the three defects hardly appear at the same time. Most of the white spots appear at the junction of the interface, white dots of different sizes; most of the cracks start from the bottom edge of the PCD chamfer and extend towards the junction of the interface, dark black and slender, with different lengths; most of the white edges appear on the Below the chamfered area of the PCD layer, it is a long white strip with different widths. In order to facilitate the comparison and analysis of the three defects, the present invention establishes a defect feature model according to the generation process, position, size and shape characteristics of the three defects, and draws the three def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com