A high-voltage direct current circuit breaker and its energy supply device

A high-voltage direct current and circuit breaker technology, which is applied in the direction of parallel operation of circuit devices, transformers, and DC power supplies, can solve the problems of large footprint and large volume, reduce voltage insulation requirements, improve operational reliability, and increase voltage levels Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] Embodiment of the energy supply device of the high-voltage DC circuit breaker:

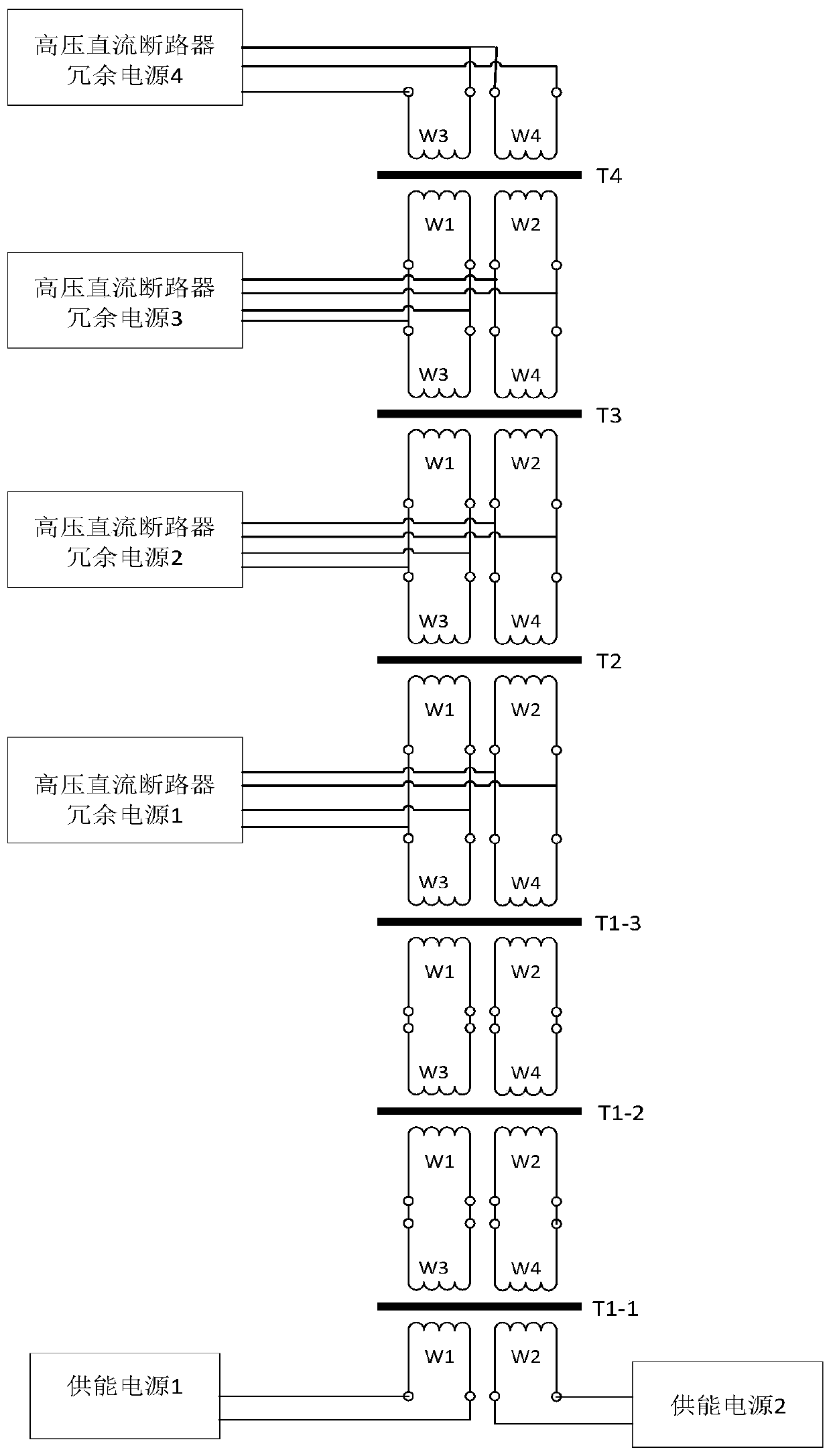

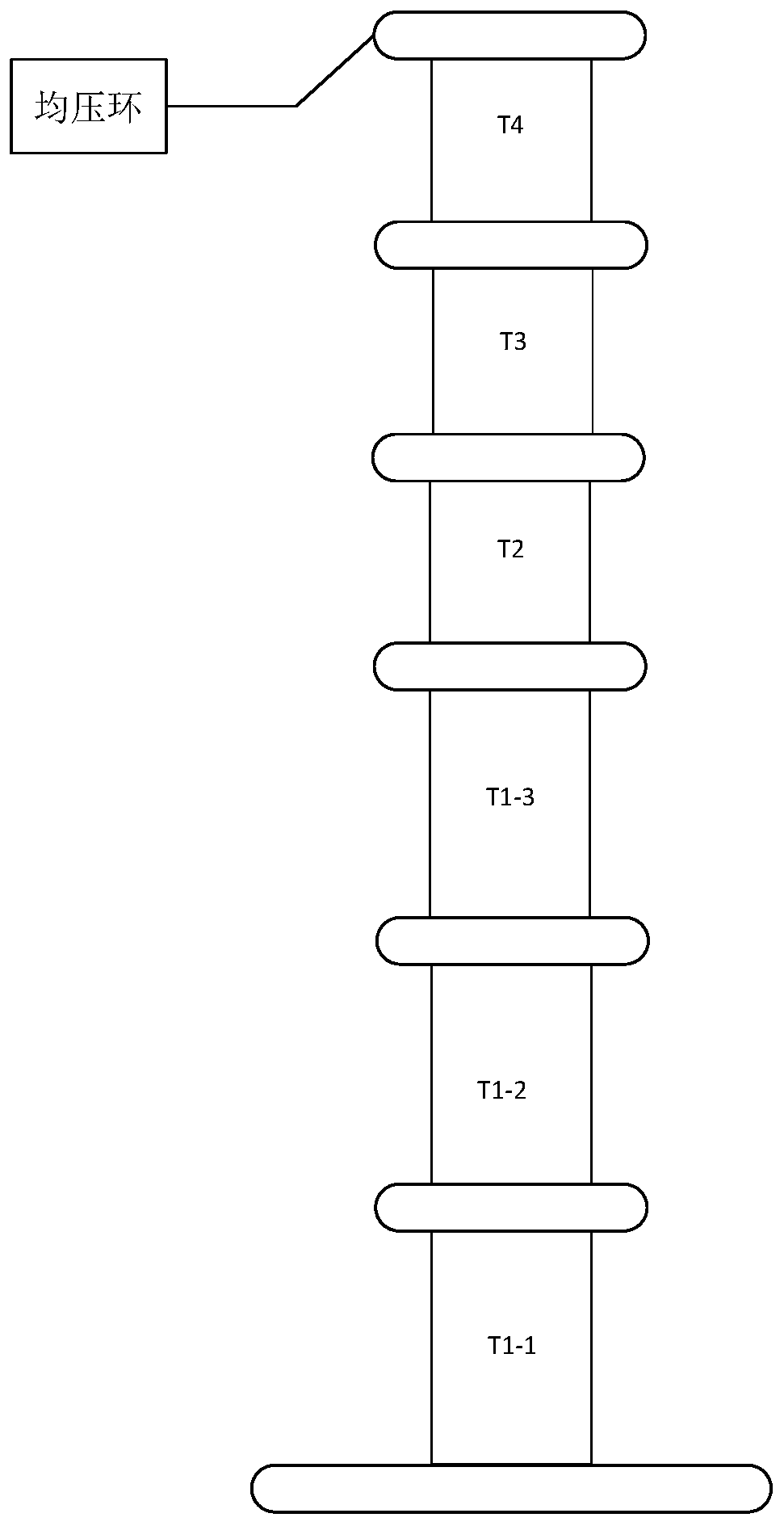

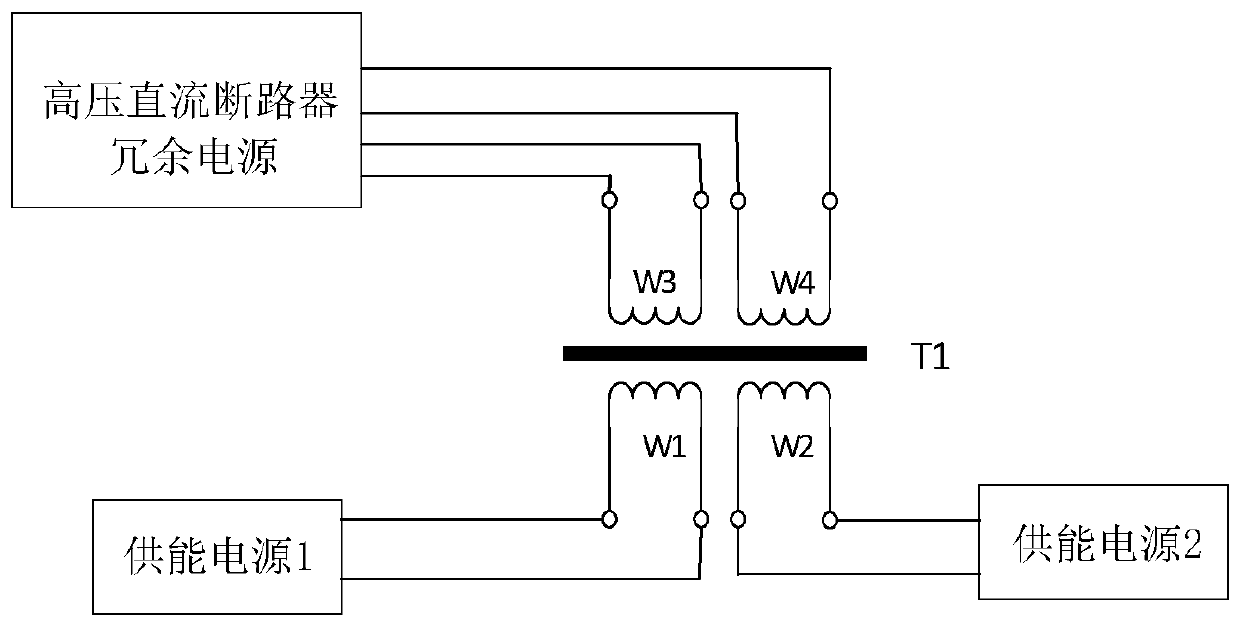

[0031] The energy supply device provided by the present invention includes n cascaded energy supply transformers and m cascaded isolation transformers, n and m can be set according to actual conditions, for example, n=3 and m=3 can be set. For each level of energy supply transformer and isolation transformer, a set of transformer core T1, two sets of primary (low voltage) windings W1 and W2 with independent rated capacity and secondary windings corresponding to two sets of primary windings W1 and W2 are used. (High voltage) windings W3 and W4, two sets of independent one-side windings and secondary windings realize redundant backup. Among them, the number of winding turns of the primary side winding W1 and W2 is the same, and the design rated power is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com