Method for controlling pre-charge state of electric vehicle

A control method and technology for electric vehicles, applied in the direction of motor control, control system, electrical components, etc., can solve the problems that the precharge resistor is not suitable for the next precharge, the precharge time is long, and the ambient temperature of the precharge resistor is high. Improve precharge efficiency, reduce precharge times, and improve precharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

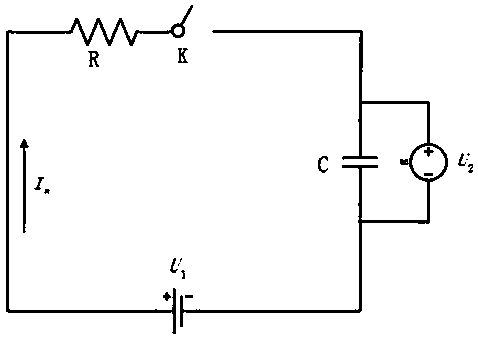

[0042] Please see attached figure 1 , a method for controlling the pre-charging state of an electric vehicle, including a pre-charging resistor R, a pre-charging relay K, a motor film capacitor C, and a battery system voltage U 1 , pre-charging resistor R, pre-charging relay K, motor film capacitor C, battery system voltage U 1 Connected as a pre-charging circuit, the load circuit voltage U 2 is the real-time voltage value across the film capacitor C of the motor.

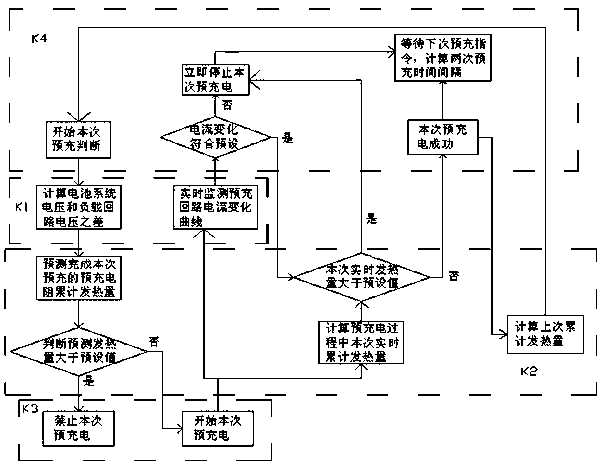

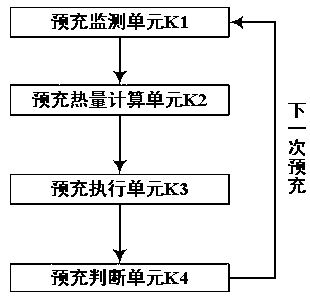

[0043] Please see attached figure 2 and attached image 3 , the method includes the following steps:

[0044] Step 1: Before the start of pre-charging, the pre-charging judging unit K4 judges whether the pre-charging condition is satisfied, and then executes step 2 after the pre-charging condition is met, otherwise, no action is taken.

[0045] Step 2: The pre-charge monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com