A constant force surface tracking method for robots based on reinforcement learning

A technology of reinforcement learning and robotics, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of rigidity robot vibration, large fluctuations, unstable contact force between robots and curved surfaces, etc., and achieve fast convergence speed and data utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

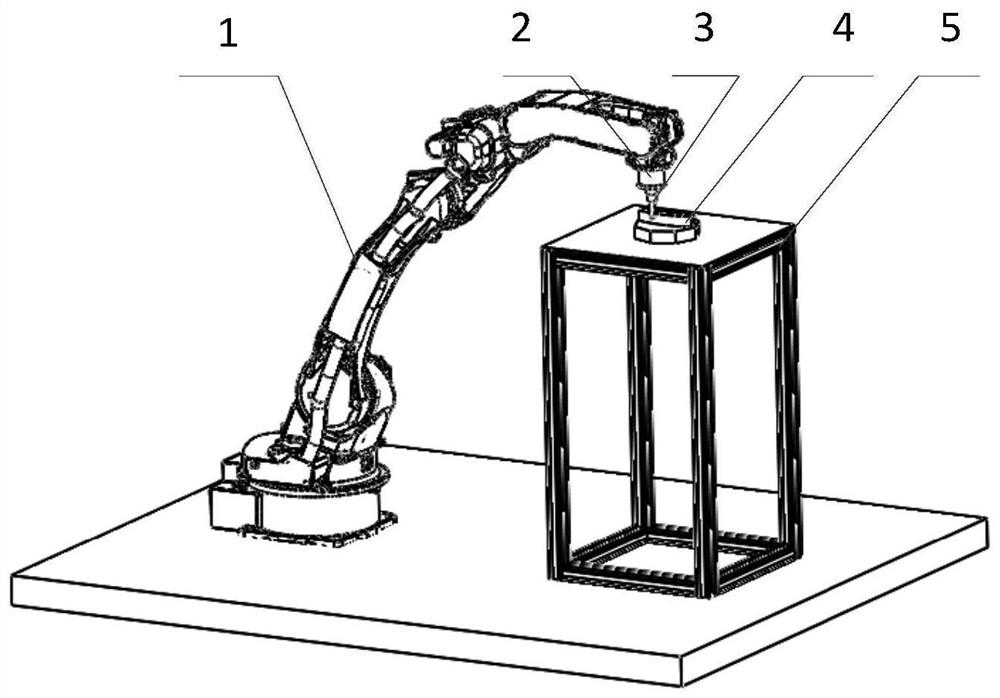

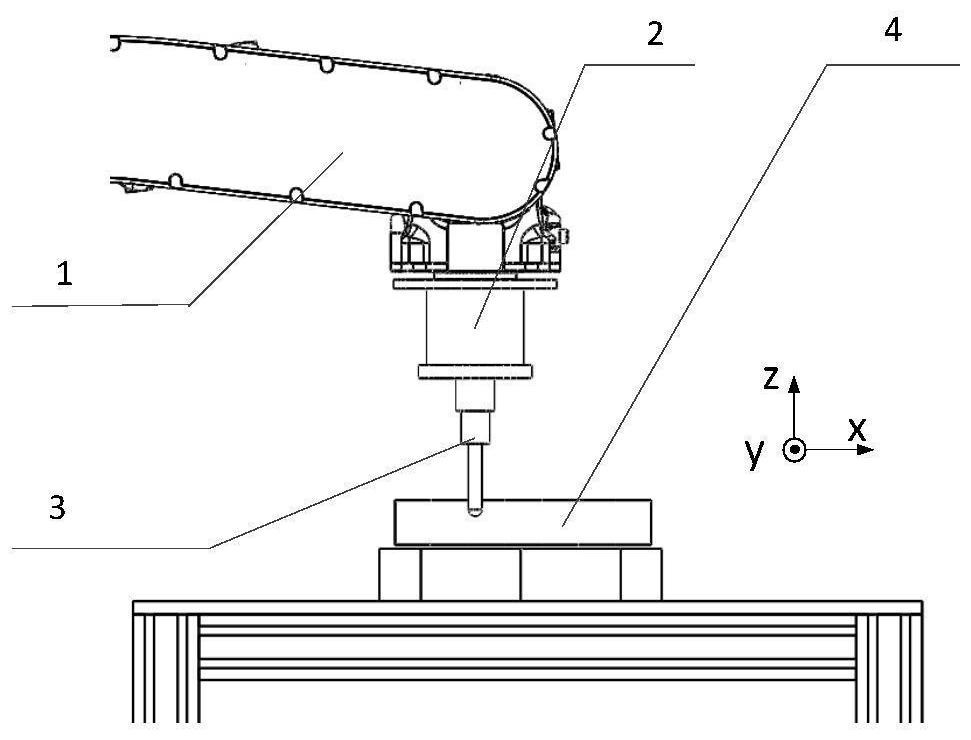

[0040] A robot constant force surface tracking method based on reinforcement learning. The method is based on a robot constant force tracking platform including a six-axis industrial robot, a workbench, a curved surface workpiece, a six-dimensional force sensor, a host computer, and a data acquisition module; Velocity moves along the x direction, and when the robot is in contact with the workpiece, it shifts along the y direction according to the magnitude of the force.

[0041] Specifically include the following steps:

[0042] (1) According to the characteristics of the 6-axis industrial robot end effector in contact with the contour of the curved surface, establish the mapping relationship between the normal force of the curved surface and the known sensor coordinate system;

[0043] (2) Design an explicit force controller to control the contact process between the robot and the curved surface;

[0044] (3) Optimize the parameters of the controller (such as the PID paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com