A train arrival automatic sewage discharge system

An automatic sewage and train technology, applied in railway car body parts, sanitary equipment, transportation and packaging, etc., can solve the problems of large impact force at the connection between the hose and the flange, difficult connection of the extraction pipe, etc. impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

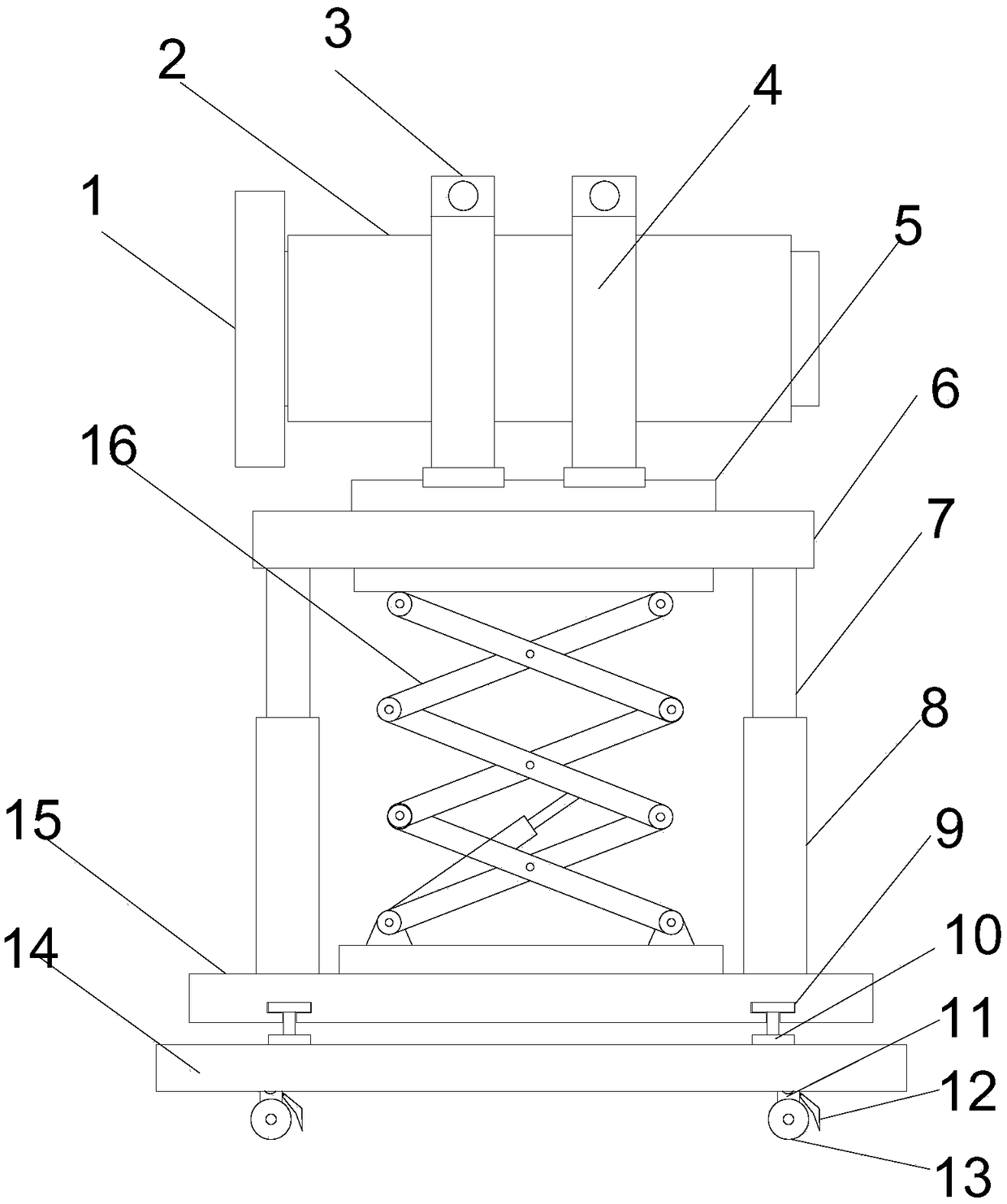

[0027] see figure 1 , an automatic sewage discharge system when a train arrives at a station, comprising a mounting plate-6, the upper surface of the mounting plate-6 is provided with a clamping device, and the clamping device includes a fixed plate-5 installed on the upper surface of the mounting plate-6, A pair of semicircular snap rings 4 are arranged perpendicular to the axis of the extraction pipe 1 on the fixed plate one 5, the lower end of the said snap rings 4 is hinged with the fixed plate one 5, and the upper ends of the snap rings 4 are all provided with connecting blocks 3, said The connecting block 3 is fixedly connected by bolts, the lower surface of the mounting plate 16 is provided with a lifting mechanism 16, and the lower end of the lifting mechanism 16 is provided with a mounting plate 2 15 and is fixedly connected, and the lower surface of the mounting plate 15 2 is provided with a groove 9 , the groove 9 is provided with a chute and is slidably connected, ...

Embodiment 2

[0030] see figure 1 , an automatic sewage discharge system when a train arrives at a station, comprising a mounting plate-6, the upper surface of the mounting plate-6 is provided with a clamping device, and the clamping device includes a fixed plate-5 installed on the upper surface of the mounting plate-6, A pair of semicircular snap rings 4 are arranged perpendicular to the axis of the extraction pipe 1 on the fixed plate one 5, the lower end of the said snap rings 4 is hinged with the fixed plate one 5, and the upper ends of the snap rings 4 are all provided with connecting blocks 3, said The connecting block 3 is fixedly connected by bolts, the lower surface of the mounting plate 16 is provided with a lifting mechanism 16, and the lower end of the lifting mechanism 16 is provided with a mounting plate 2 15 and is fixedly connected, and the lower surface of the mounting plate 15 2 is provided with a groove 9 , the groove 9 is provided with a chute and is slidably connected, ...

Embodiment 3

[0035] see figure 1 , an automatic sewage discharge system when a train arrives at a station, comprising a mounting plate-6, the upper surface of the mounting plate-6 is provided with a clamping device, and the clamping device includes a fixed plate-5 installed on the upper surface of the mounting plate-6, A pair of semicircular snap rings 4 are arranged perpendicular to the axis of the extraction pipe 1 on the fixed plate one 5, the lower end of the said snap rings 4 is hinged with the fixed plate one 5, and the upper ends of the snap rings 4 are all provided with connecting blocks 3, said The connecting block 3 is fixedly connected by bolts, the lower surface of the mounting plate 16 is provided with a lifting mechanism 16, and the lower end of the lifting mechanism 16 is provided with a mounting plate 2 15 and is fixedly connected, and the lower surface of the mounting plate 15 2 is provided with a groove 9 , the groove 9 is provided with a chute and is slidably connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com