Automatic lifting platform capable of quickly running and locating with high precision, and elevator

An automatic lifting and high-precision technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of complex design and installation, danger, and many layers of poles, etc., to achieve simple and easy design, safe and reliable lifting, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 An automatic lifting platform with fast operation and high-precision positioning

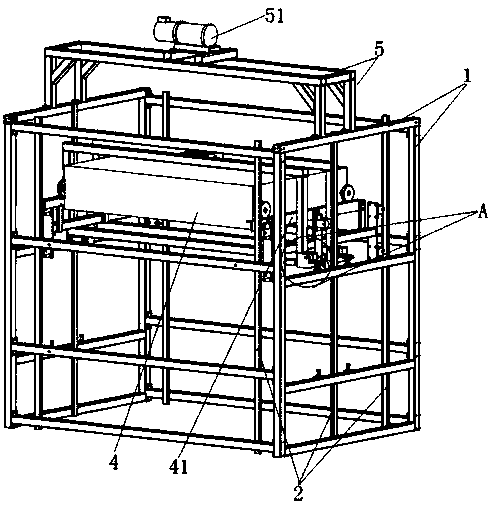

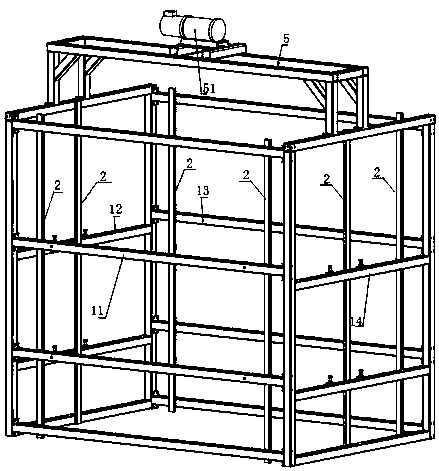

[0039] Such as figure 1 As shown, an automatic lifting platform with fast operation and high-precision positioning includes a support frame 1, a lifting mobile platform arranged in the support frame 1, and a lifting drive mechanism that drives the lifting mobile platform to perform lifting movements.

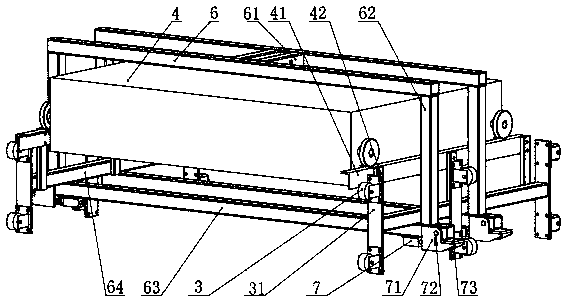

[0040] The support frame 1 is provided with a guide rail 2, and the two sides of the lifting mobile platform are provided with track wheels 3 matched with the guide rail 2, and the lifting mobile platform can move up and down on the guide rail 2; the lifting mobile platform includes a working vehicle 4 and a working vehicle track 41, The working car 4 is provided with rollers matching the working car track 41, and the working car 4 can move left and right on the working car track 41; Card position to adjust the stop height of the lifting mobile platform. The top of the suppor...

Embodiment 2

[0049] Embodiment 2 A lift

[0050] The present invention also provides a lift, using the fast running and high-precision positioning automatic lifting platform provided by the above-mentioned embodiment 1, the specific description is as follows:

[0051] The elevator adopts the fast running and high-precision automatic lifting platform provided by the above-mentioned embodiment 1, which can realize the lifting of the lifting platform relatively quickly. This process only requires simple driving control of the driving handle and the lifting drive mechanism, and does not Relying on complex control methods and expensive precision sensors, while realizing the increase in lifting speed, it also ensures the reliability of the lifting platform. and control complexity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com