Preparation method of superhydrophobic material as well as product and application

A super-hydrophobic and distilled water technology, applied in the field of polymer materials, can solve the problems of general scale inhibition effect, achieve the effects of preventing calcium sulfate scaling, reducing risks, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

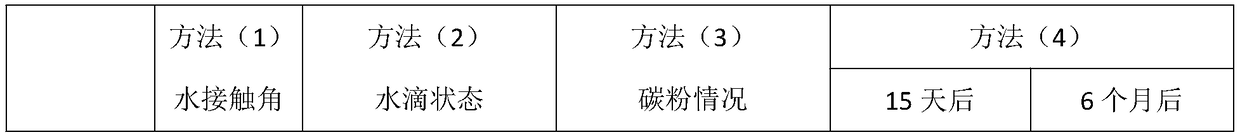

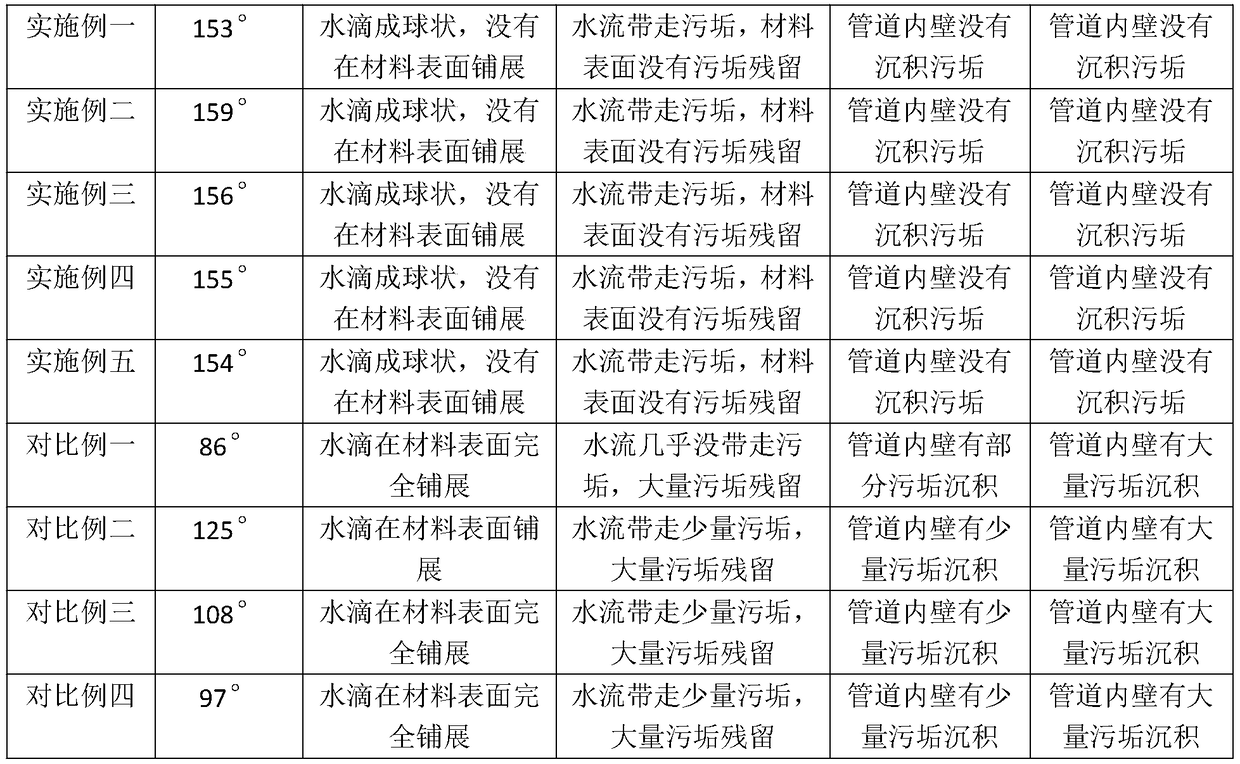

Examples

Embodiment 1

[0035] (1) Weigh 10g of sodium silicate solution in a beaker, add 50ml of distilled water, and ultrasonicate for 5-15 minutes to completely dissolve the sodium silicate solution;

[0036] (2) Heat the sodium silicate solution in the beaker, keep the temperature at 35°C, add 5mol / L hydrochloric acid dropwise to the beaker for reaction, the volume of hydrochloric acid added is 0.8 times the volume of the sodium silicate solution, until white Suspension, the reaction is completed, the white suspension is suction filtered to obtain a precipitate, the precipitate is washed repeatedly with distilled water, and AgNO 3 Solution Detection of Cl in wash solution - , until no AgCl precipitate is generated in the washing solution; the precipitate is dried at 60°C under normal pressure to obtain hydrated silica;

[0037] (3) Add 100g of the hydrated silicon dioxide prepared above and 80mL of absolute ethanol into a 250mL three-necked flask, slowly drop 6ml of vinyltriethoxysilane into the...

Embodiment 2

[0042] (1) Weigh 10g of sodium silicate solution in a beaker, add 50ml of distilled water, and ultrasonicate for 5-15 minutes to completely dissolve the sodium silicate solution;

[0043] (2) Heat the sodium silicate solution in the beaker, keep the temperature at 37°C, add 5mol / L hydrochloric acid dropwise to the beaker for reaction, the volume of hydrochloric acid added is 0.9 times the volume of the sodium silicate solution, until white Suspension, the reaction is completed, the white suspension is suction filtered to obtain a precipitate, the precipitate is washed repeatedly with distilled water, and AgNO 3 Solution Detection of Cl in wash solution - , until no AgCl precipitate is generated in the washing solution; the precipitate is dried at 65°C under normal pressure to obtain hydrated silica;

[0044] (3) Add 100g of the hydrated silicon dioxide prepared above and 90mL of absolute ethanol to a 250mL three-necked flask, slowly drop 7ml of vinyltriethoxysilane into the t...

Embodiment 3

[0049] (1) Weigh 10g of sodium silicate solution in a beaker, add 50ml of distilled water, and ultrasonicate for 5-15 minutes to completely dissolve the sodium silicate solution;

[0050] (2) Heat the sodium silicate solution in the beaker, keep the temperature at 40°C, add 5mol / L hydrochloric acid dropwise to the beaker for reaction, the volume of hydrochloric acid added is 1 times the volume of the sodium silicate solution, until white Suspension, the reaction is completed, the white suspension is suction filtered to obtain a precipitate, the precipitate is washed repeatedly with distilled water, and AgNO 3 Solution detection of Cl in wash solution - , until no AgCl precipitate is formed in the washing solution; dry the precipitate at 70°C under normal pressure to obtain hydrated silica;

[0051] (3) Add 100g of the hydrated silicon dioxide prepared above and 100mL of absolute ethanol to a 250mL three-necked flask, slowly drop 8ml of vinyltriethoxysilane into the three-neck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com