Onion oil and preparation method thereof

A technology of onion oil and onion, which is applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve problems such as being unsuitable for large-scale production, high energy consumption, solvent residue, etc., and reduce the presence of unfavorable components in the human body. possibility, simple production process, no solvent residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Take fresh onions, peel and clean them, then mechanically crush them to 2-4cm sized onion particles, add soybean oil at a ratio of 1:1 and mix evenly, extract at 25-35°C for 60 minutes at low temperature, press for 100 minutes after removing the slag Stand and stratify, get the onion emulsion of the upper layer and carry out centrifugation, the rotating speed is 15000r / min, the centrifugation time is 15min, filtration, filtrate filling can get yellow transparent onion oil.

Embodiment 2

[0012] Take fresh onions, peel and clean them, then mechanically crush them to 2-4cm size onion particles, add soybean oil in a ratio of 1:1 and mix evenly, leaching at 25-35°C for 240min at low temperature, pressing to remove slag, and then 120min Stand and stratify the onion emulsion, get the upper layer of onion emulsion and carry out centrifugal separation, the rotating speed is 10000r / min, the centrifugation time is 20min, filtration, filtrate filling can get yellow transparent onion oil.

Embodiment 3

[0014] Take fresh onions, peel and clean them, then mechanically crush them to 2-4cm sized onion particles, add soybean oil at a ratio of 1:1 and mix evenly, leaching at 25-35°C for 180min at low temperature, pressing to remove slag, and then 60min Stand and stratify, get the onion emulsion of the upper layer and carry out centrifugation, the rotating speed is 5000r / min, the centrifugation time is 30min, filtration, filtrate filling can get yellow transparent onion oil.

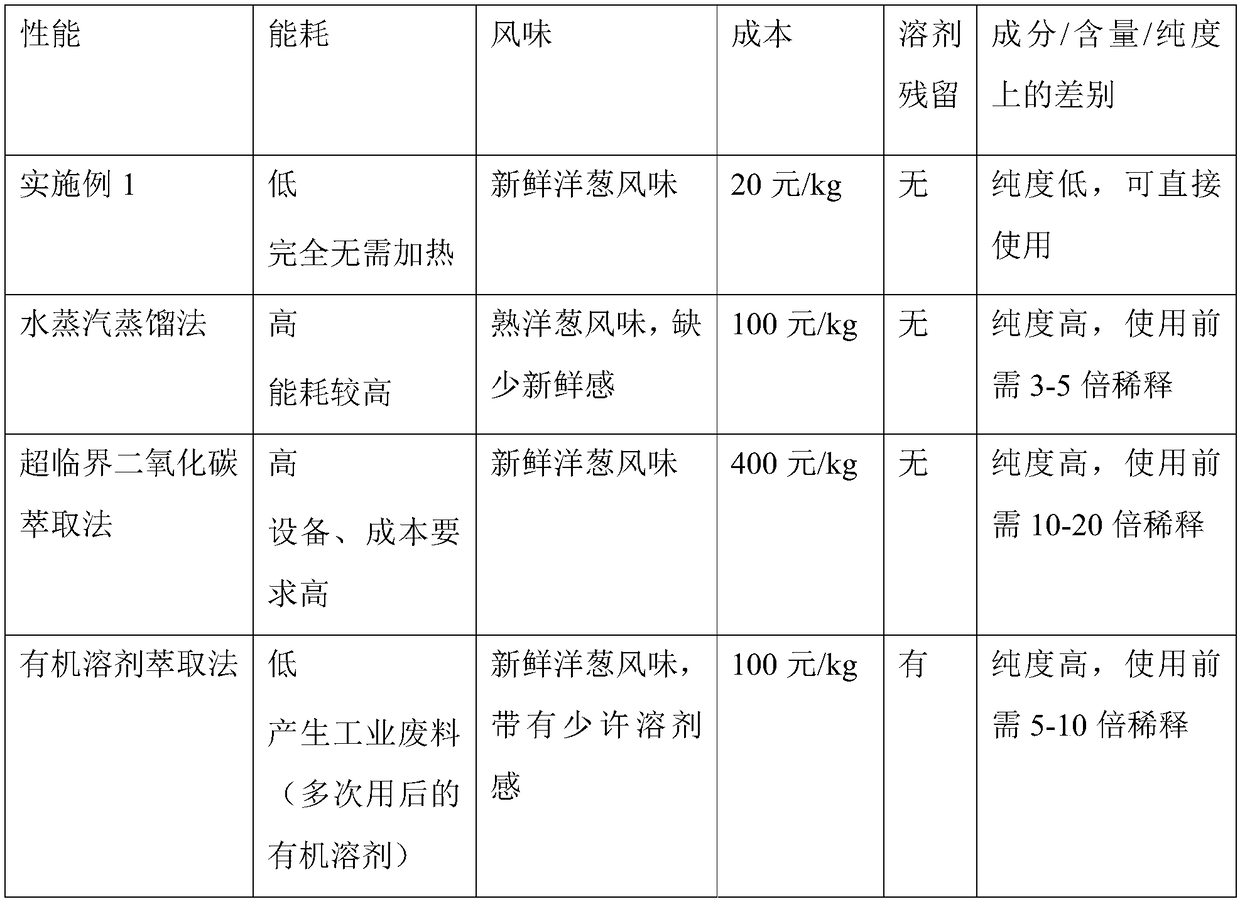

[0015] Compared with the extraction method in the prior art, the onion oil prepared by the method of the present invention has advantages and disadvantages as shown in Table 1 below.

[0016] Table 1. The comparison of the method of embodiment 1 of the present invention and the onion oil it makes with several methods in the prior art.

[0017]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap