A wooden sliding door structure

A sliding door, wood technology, applied in the direction of door leaf, window/door, building components, etc., can solve the problems of falling off the sleeve, time-consuming and laborious, and structural damage of the whole sliding door.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

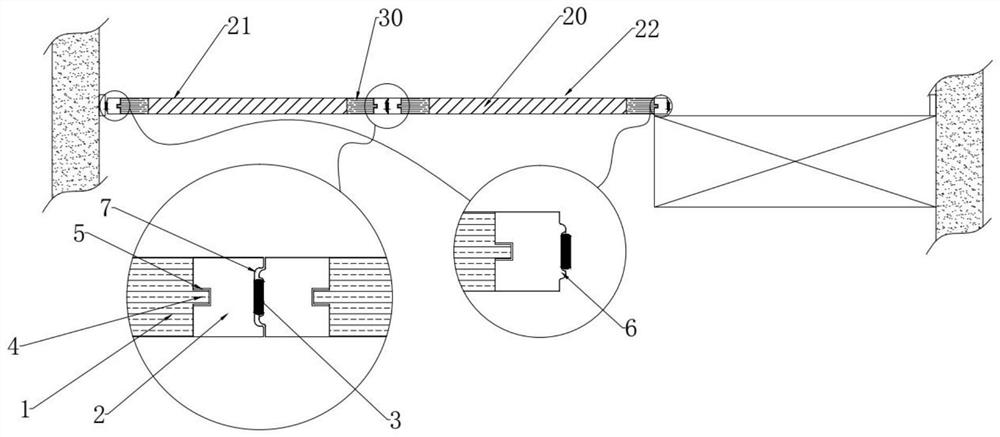

[0022] combine figure 1 and figure 2 The wooden sliding door structure shown, in this embodiment, includes a slideway and a sliding door that slides in the slideway. The sliding door includes a door leaf plate 20 and two composite vertical sides connected with the door leaf plate 20 through mortise and tenon or screws. The stile 30, the upper stile and the lower stile, two composite vertical stiles 30 are arranged between the upper stile and the lower stile, and the composite vertical stile 30, the upper stile and the lower stile are connected by mortise and tenon or screws, and the composite vertical edge The stile 30 includes a first vertical side stile 1 and a second vertical side stile 2 connected by mortise and tenon. The sides of the two vertical stiles 2 facing away from the first vertical stile 1 are provided with sealing strips 3 , and the width of the second vertical stile 2 is smaller than the width of the first vertical stile 1 .

[0023] combine figure 1 and ...

Embodiment 2

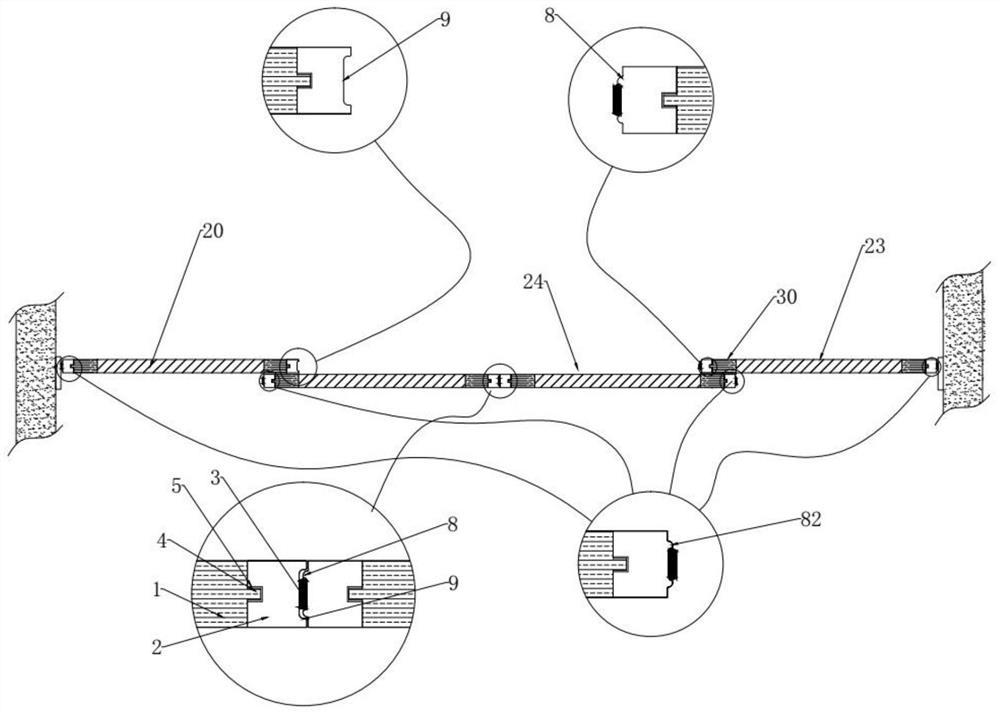

[0026] combine figure 1 , image 3 and Figure 4 The wooden sliding door structure shown, in this embodiment, includes a slideway and a sliding door that slides in the slideway. The sliding door includes a door leaf plate 20 and two composite vertical sides connected with the door leaf plate 20 through mortise and tenon or screws. The stile 30, the upper stile and the lower stile, two composite vertical stiles 30 are arranged between the upper stile and the lower stile, and the composite vertical stile 30, the upper stile and the lower stile are connected by mortise and tenon or screws, and the composite vertical edge The stile 30 includes a first vertical side stile 1 and a second vertical side stile 2 connected by mortise and tenon. The sides of the two vertical stiles 2 facing away from the first vertical stile 1 are provided with sealing strips 3 , and the width of the second vertical stile 2 is smaller than the width of the first vertical stile 1 .

[0027] combine fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com