Hydraulic motion system

A motion system and hydraulic technology, applied in the field of hydraulics, can solve problems such as labor and labor, and achieve the effects of clear principles, quick results, and easy popularization and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

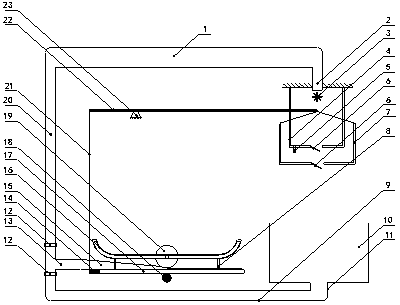

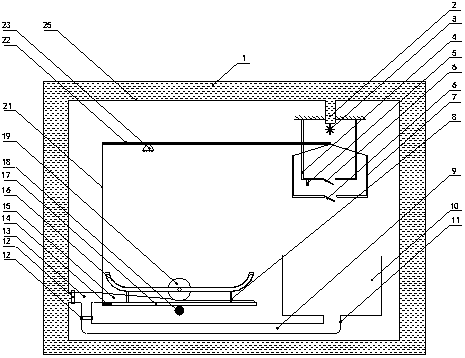

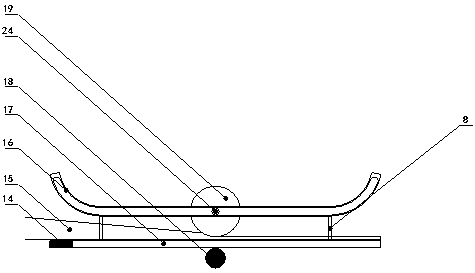

[0028] The hydraulic exercise system of the present invention will be further described in detail below in conjunction with the above-mentioned accompanying drawings.

[0029] In the hydraulic exercise system of the present invention, the hose 15 is sandwiched between the seesaw 17 and the roller 19 .

[0030] The hydraulic motion system of the present invention has two kinds of land type and submerged type:

[0031] A. Land type: One end of the hose 15 is sealed with a broken end, the other end is connected to the return pipe 20 and the lower pipe 9 through the three-way fitting 13, and one end of the lower pipe 9 is connected to the return pipe 20 and the hose 15 through the three-way fitting 13, and the other One end is connected with the low-level pool 10, one end of the return pipe 20 is connected with the water belt 15 and the low-level pipe 9 through the three-way fitting 13, and one end is connected with the high-level pool 1, and the high-level pool 1 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com