Liquefied gas storage tank liquid level meter pipeline ice blockage prevention device

A technology of liquefied gas and liquid level gauge, which is applied in the installation device of container structure, gas/liquid distribution and storage, method of container discharge, etc., to achieve the effect of reducing impact, preventing ice blockage and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

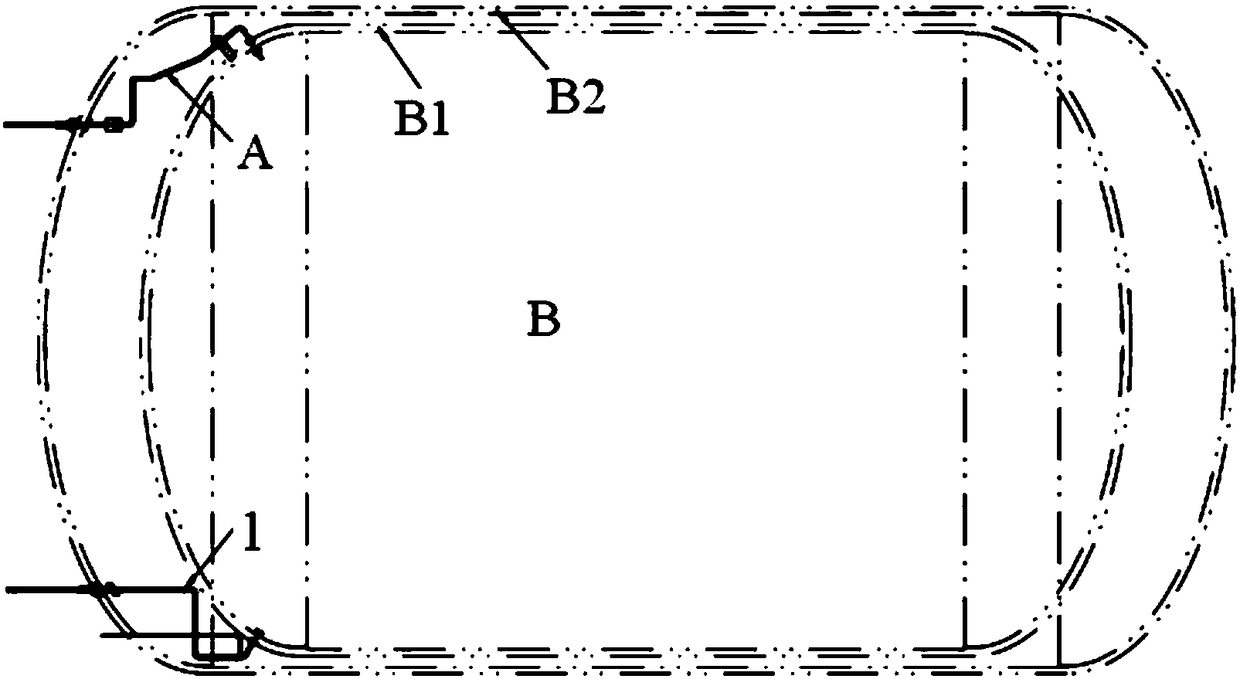

[0024] This specific embodiment discloses a method for preventing local ice blockage of a liquid level gauge, wherein the liquid level gauge is used to measure the liquid level of a low-temperature liquefied gas storage tank, and one end of the liquid level gauge is connected to the gas phase pipe A, and the other end is connected to the liquid phase pipe 1 Unicom, the method to prevent the ice blockage of the liquid level gauge is to locally heat the liquid phase pipe 1 of the liquid level gauge.

[0025] Specifically, the part of the local heating is the position where the liquid phase pipe 1 of the liquid level gauge is prone to ice blockage, and the position where the liquid phase pipe 1 is prone to ice blockage is the position where the liquid phase pipe 1 is close to the inner tank B1 of the low-temperature liquefied gas storage tank B Straight pipe position.

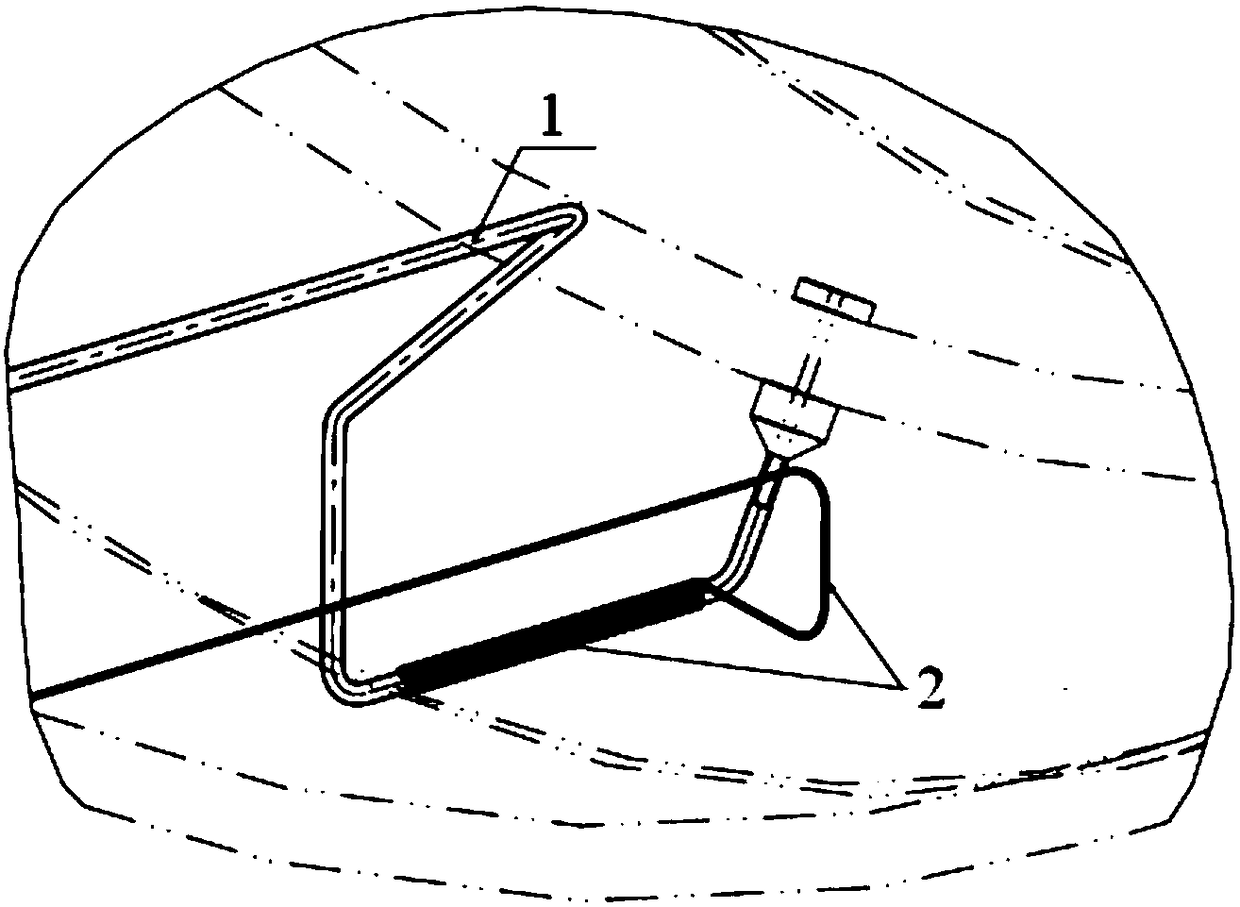

[0026] Specifically, local electric heating is performed on the liquid phase pipe 1 of the liquid level gauge. ...

Embodiment 2

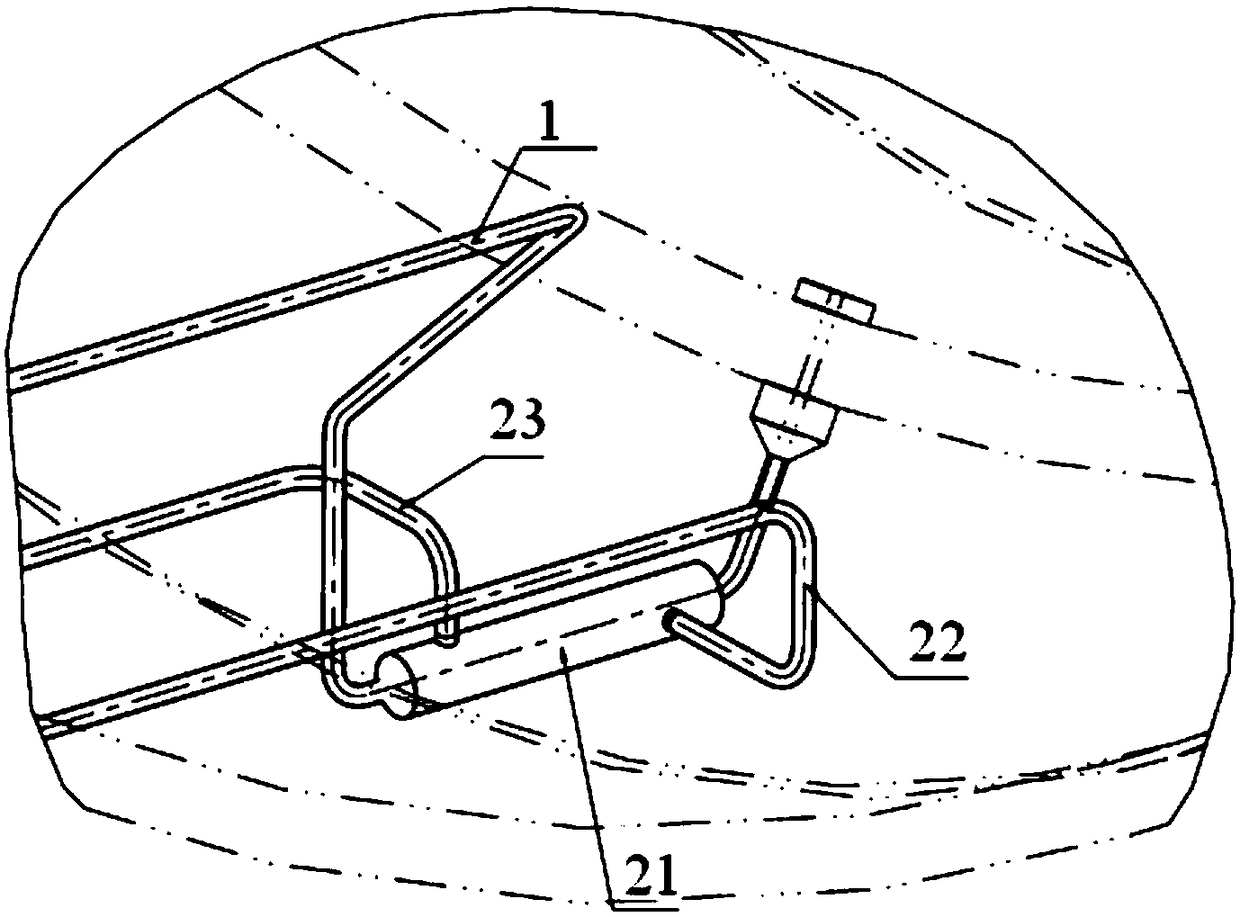

[0029] The method for preventing local ice blockage of the liquid level gauge disclosed in the second embodiment is basically the same as that in the first embodiment, except that the heating methods in the two embodiments are different. In this embodiment, the liquid phase pipe 1 of the liquid level gauge is locally heated by the heat exchange medium.

[0030] Specifically, a casing is sleeved outside a local area of the liquid phase tube 1 of the liquid level gauge, and a cavity is formed between the sleeve tube and the liquid phase tube 1 of the liquid level gauge, and an inlet connecting pipe is provided at both ends of the cavity 22 and an outlet connecting pipe 23, the inlet connecting pipe 22 is used to introduce the heat exchange medium into the cavity, and the outlet connecting pipe 23 is used to export the heat exchange medium in the cavity. In this embodiment, the heat exchange medium may be gas and / or liquid.

[0031] By controlling the flow rate and temperature...

Embodiment 3

[0034] The method for preventing local ice blockage of the liquid level gauge disclosed in the third embodiment is basically the same as that in the second embodiment, both of which are heated by the heat exchange medium, and the difference is that the heating device 2 in the two embodiments different.

[0035] Specifically, in this embodiment, a spiral tube is arranged outside the liquid phase tube 1 of the liquid level gauge, and the spiral tube is wound around a local area of the liquid phase tube 1 of the liquid level gauge, and the spiral tube is used for passing the heat exchange medium.

[0036] Compared with the second embodiment, the heating medium in this embodiment is not in direct contact with the liquid phase pipe 1 of the liquid level gauge, so that the setting can avoid the corrosion of the liquid phase pipe by the heating medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com