Dual-element combined high-frequency sinusoidal pressure generator and pressure generation method

A combination and generator technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problem of not being able to obtain the ideal output response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

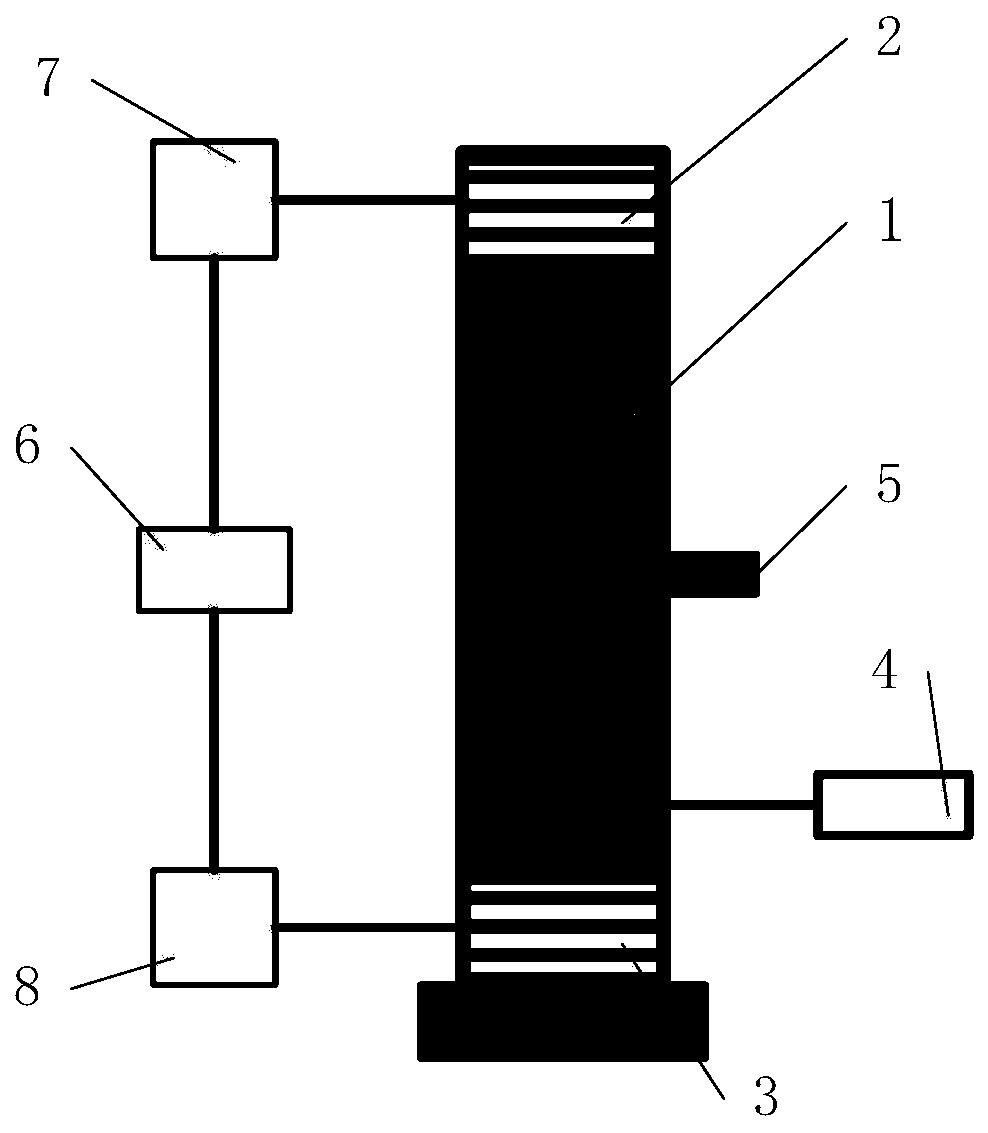

[0042] The binary combined high-frequency sinusoidal pressure generator disclosed in this embodiment includes a hydraulic pipeline 1, a top piezoelectric transducer 2, a bottom piezoelectric transducer 3, a pressure controller 4, a pressure measurement chamber 5, and a signal generator 6. Top power amplifier 7, bottom power amplifier 8.

[0043] The hydraulic pipeline 1 is a hollow cylindrical structure filled with a liquid medium, the bottom is fixedly connected to the bottom piezoelectric transducer 3, the top is fixedly connected to the top piezoelectric transducer 2, and the center is fixedly connected to the pressure measurement chamber 5;

[0044] The hydraulic pipeline 1, the top piezoelectric transducer 2 and the bottom piezoelectric transducer 3 have the following relationship:

[0045] The top piezoelectric transducer 2 and the bottom piezoelectric transducer 3 are jointly affected by the signal generator 6, the top power amplifier 7, and the bottom power amplifier 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com