True triaxial test device for combustible ice sediments

A test device and true triaxial technology, applied in the field of rock and soil mechanics, can solve the problems that cannot meet the requirements of true triaxial test, and achieve the effect of avoiding mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

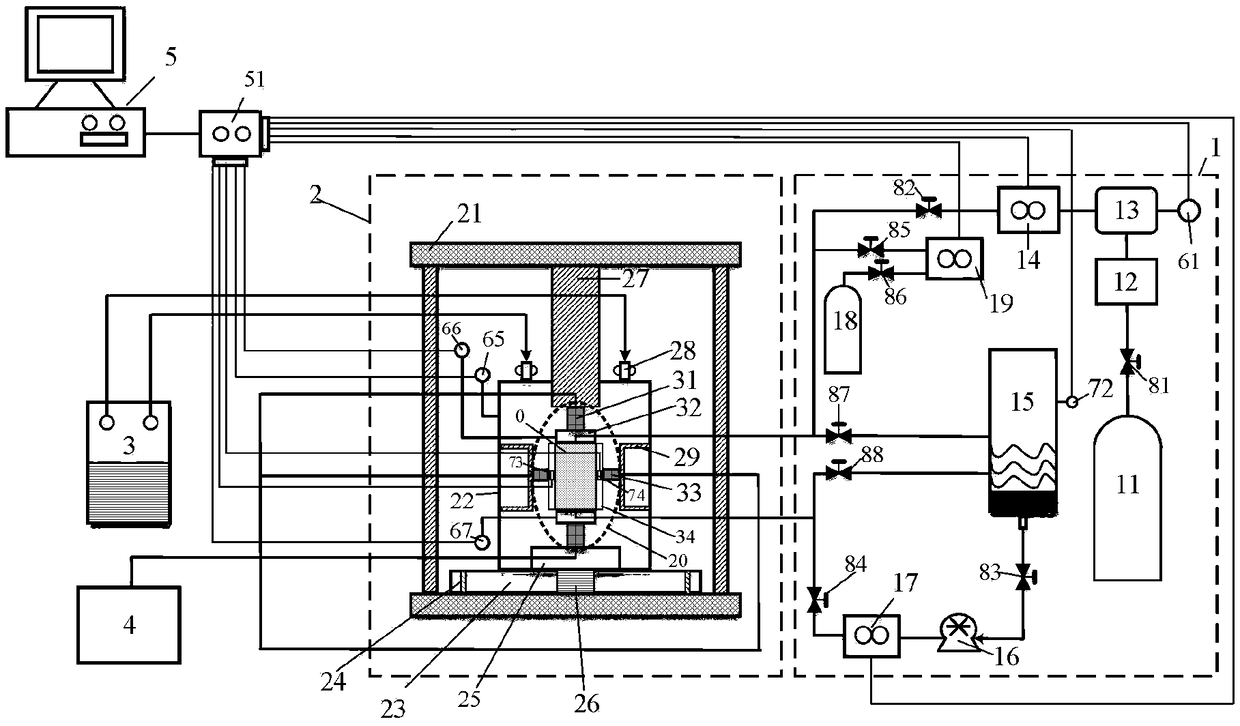

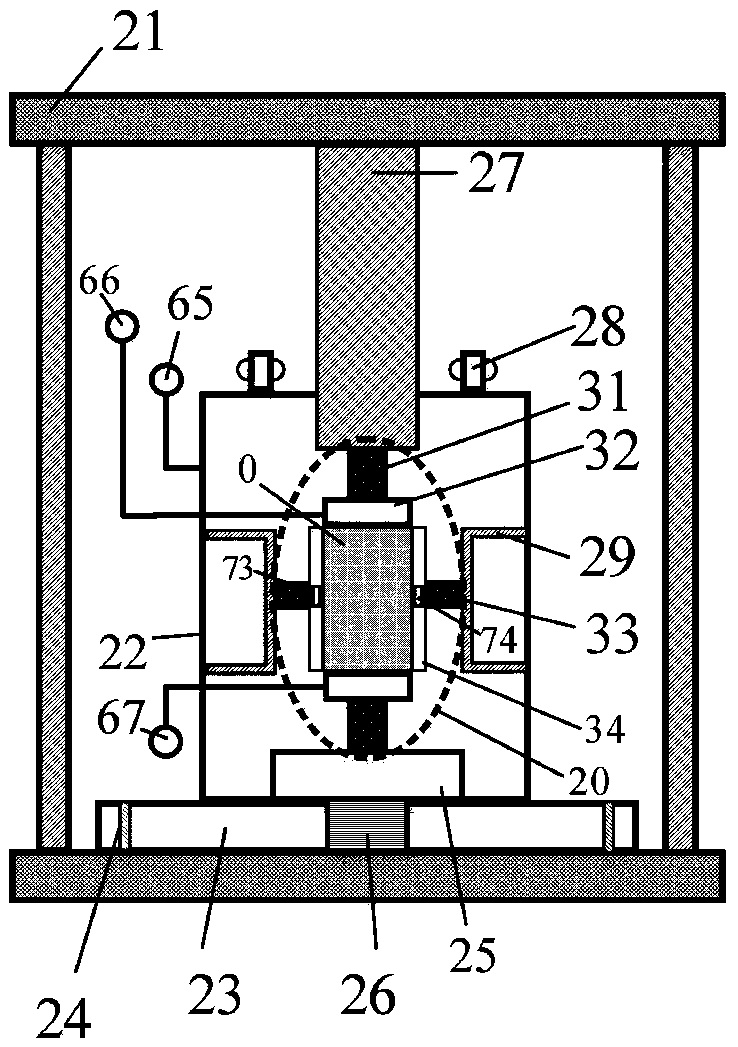

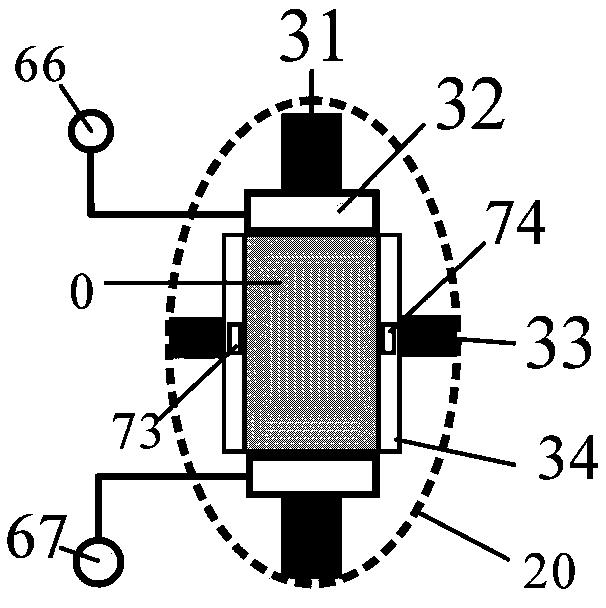

[0056] Such as Figure 1 to Figure 10 As shown, a true triaxial test device for combustible ice deposits, including:

[0057] The air-water supply-recovery component 1 forms an air source circulation channel and a water source circulation channel with the sample 0 in the true triaxial loading component 2;

[0058] True triaxial loading component 2, which provides pressure loading on the sample 0 in the directions of up and down, left and right, and front and rear axes;

[0059] The temperature control device 3 provides temperature control to the temperature chamber 22 in the true triaxial loading assembly 2;

[0060] The pressure control device 4 controls the pressure loading in the directions of the up and down, left and right, and front and rear axes in the true triaxial loading assembly 2;

[0061] Information processing systems for data collection and control;

[0062] Wherein, the true triaxial loading assembly includes a true triaxial loading device 20, a force frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com