Battery insulation detection circuit and control method thereof

A detection circuit and control method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low detection accuracy of negative insulation resistance, poor actual use, long data processing time, etc., and achieve real-time performance Good, low hardware cost, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

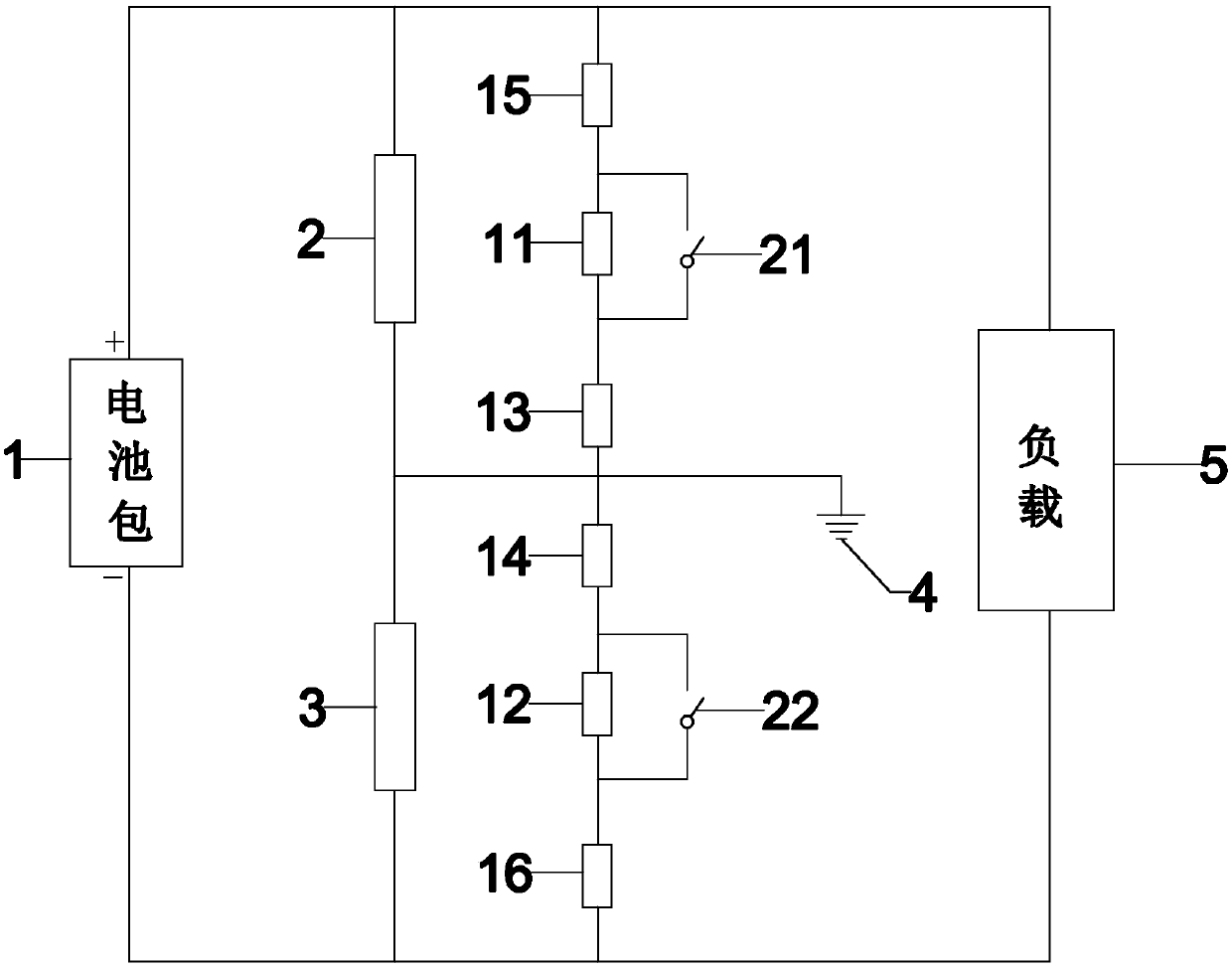

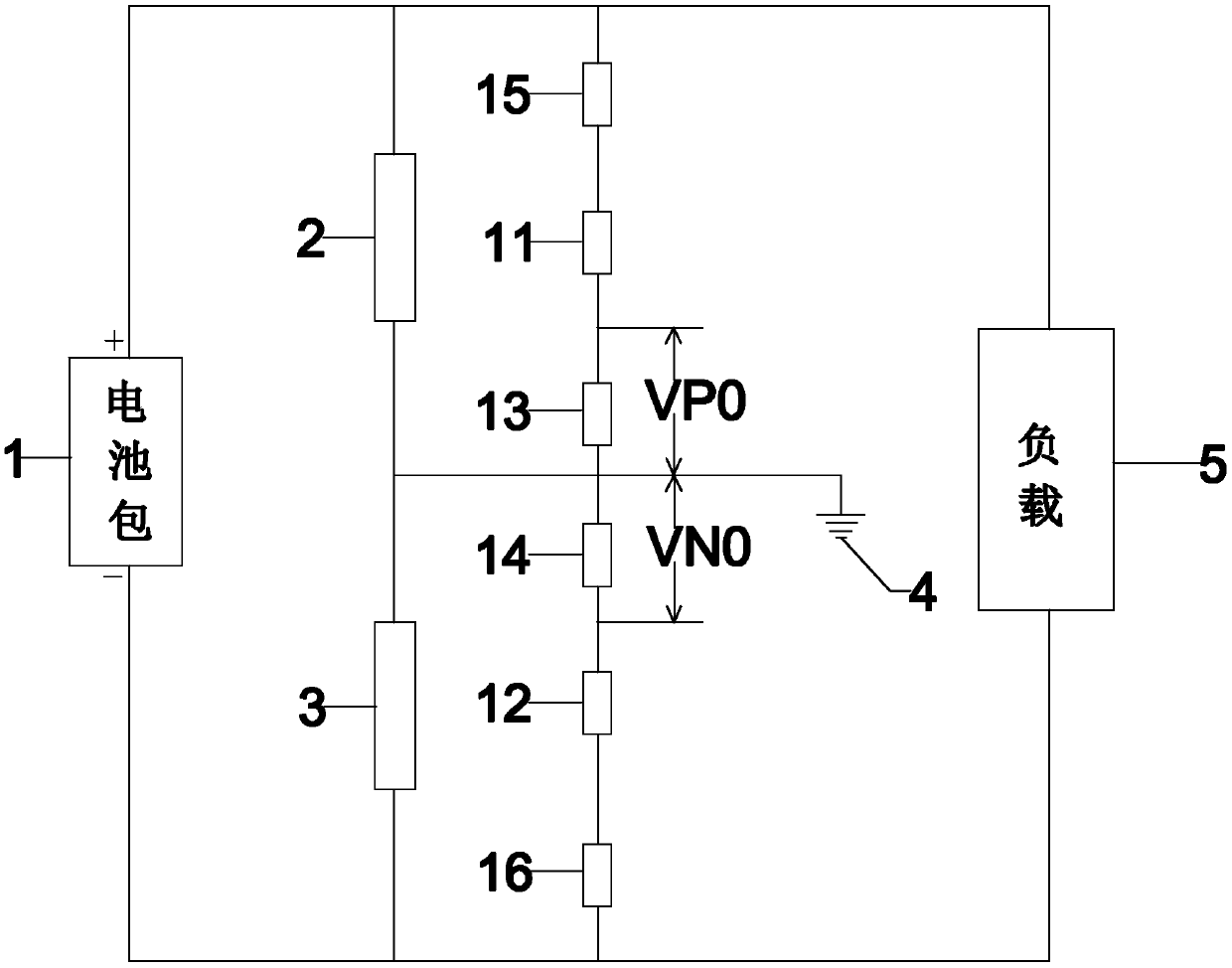

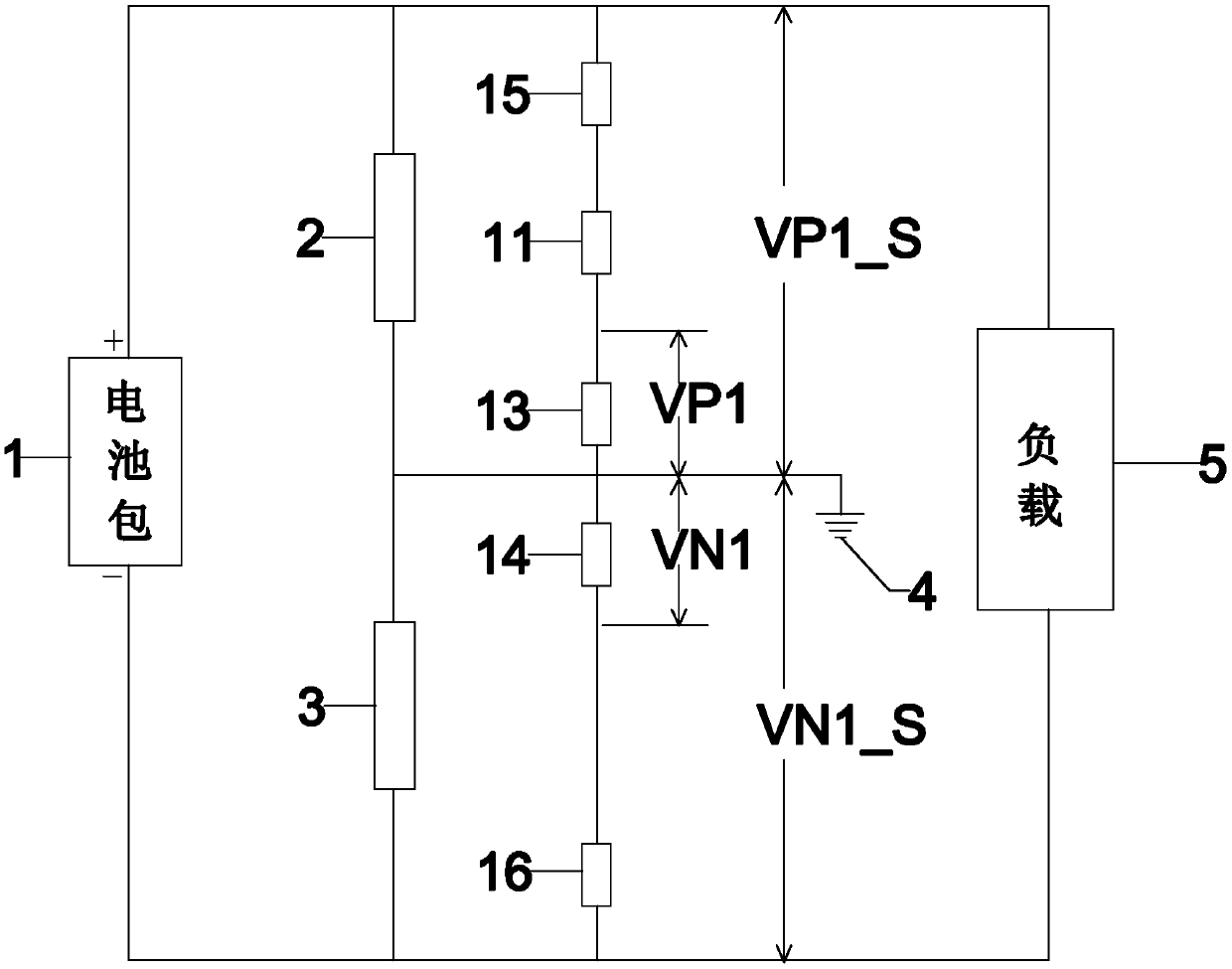

[0033] Such as figure 1 As shown in -5, the present invention is a battery insulation detection circuit, which is characterized in that it includes a battery pack 1, a positive insulation resistance 2, a negative insulation resistance 3, a first resistor 11, a second resistor 12, a third resistor 13, a Four resistors 14, a load resistor 5, a first controllable switch 21, and a second controllable switch 22, wherein: one end of the positive insulation resistor 2 is connected to one end of the first resistor 11, the first controllable switch 21 is connected to one end of the load resistor 5, and its common end is connected to the positive output terminal of the battery pack 1; the other end of the first resistor 11 is connected to the other end of the first controllable switch 21 , whose common end is connected to one end of the third resistor 13; the other end of the positive insulation resistor 2 is connected to the other end of the third resistor 13, one end of the negative i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com