Optimization scheduling method for sheet metal machining process in manufacture of computer case

A technology for optimizing scheduling and processing, applied in the direction of electrical program control, control/regulation system, program control, etc., to improve production efficiency and shorten sheet metal processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

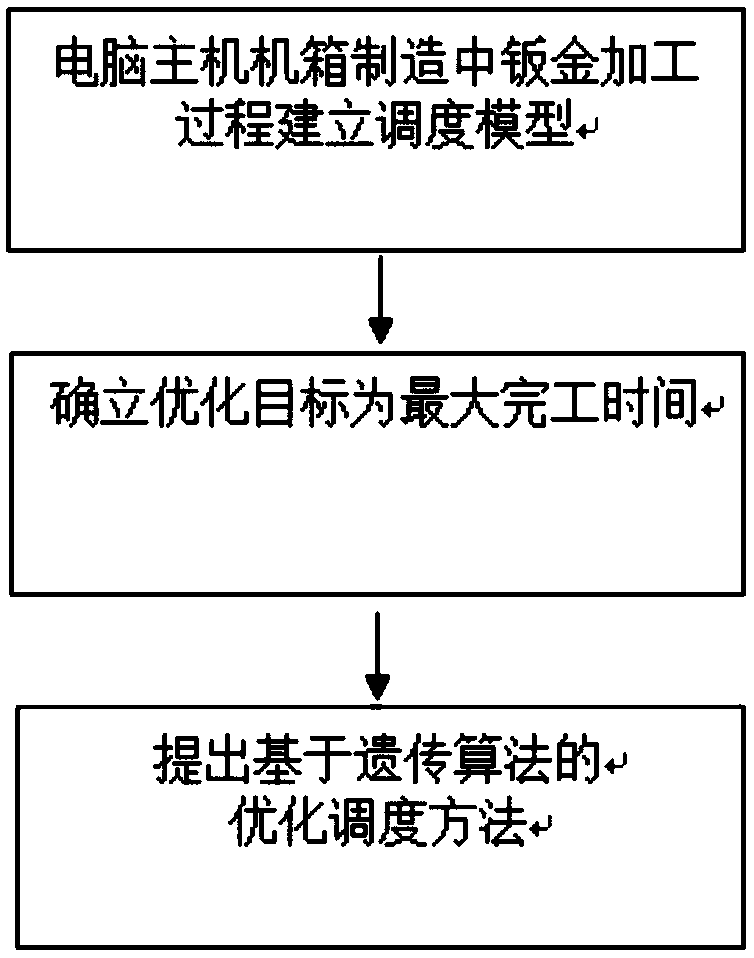

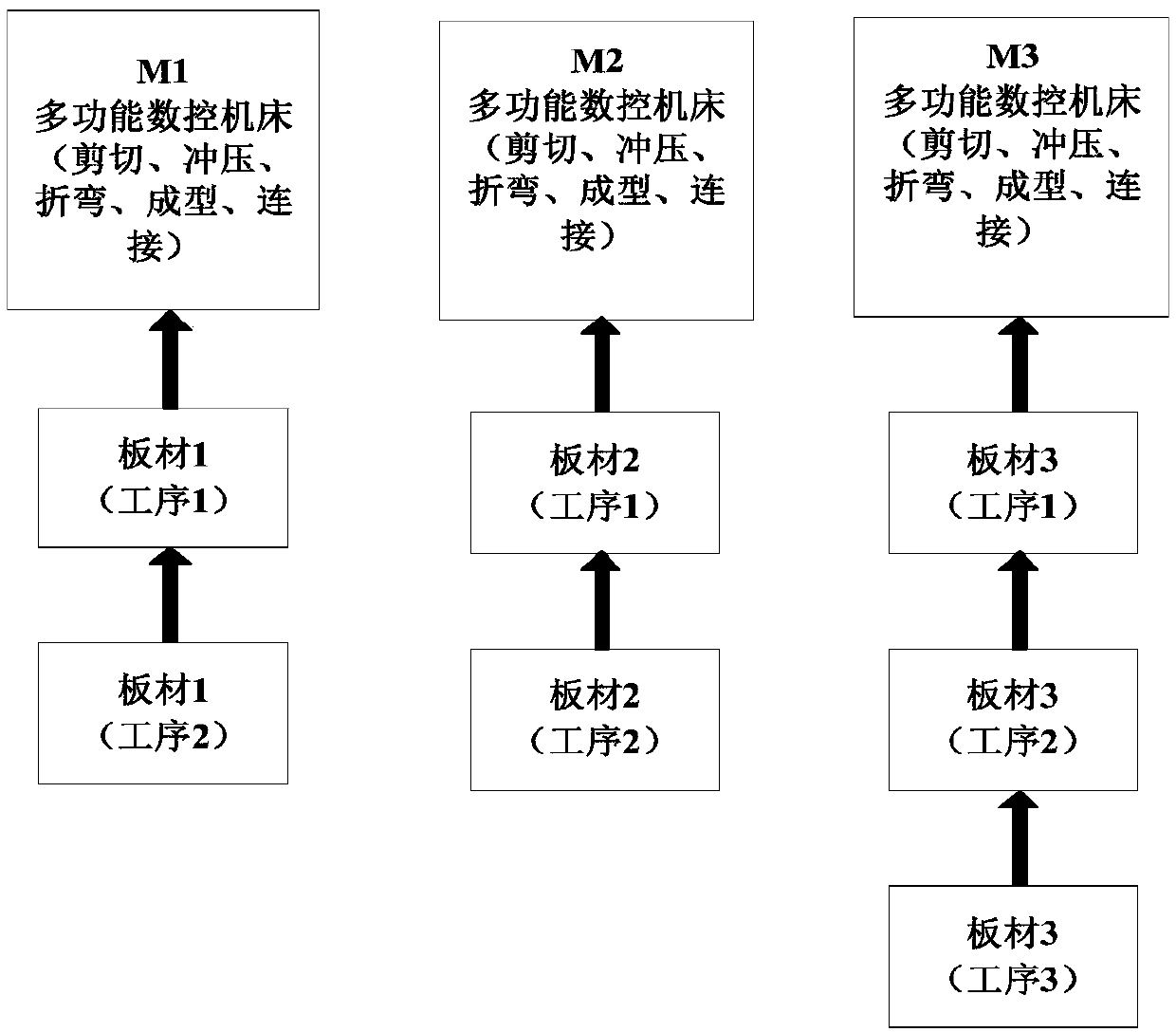

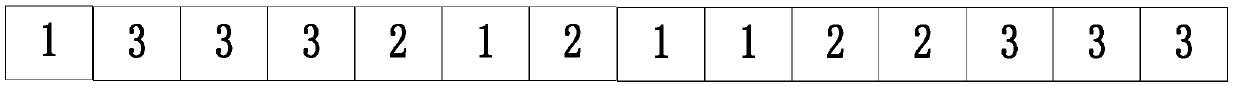

[0039] Embodiment 1: as Figure 1-5 As shown, an optimal scheduling method for the sheet metal processing process in the manufacture of computer mainframe chassis. Firstly, through on-site measurement or prior knowledge, the uncertain processing time is represented by fuzzy numbers. Affected by many uncertain factors, the processing time cannot be accurately predicted, and the completion time and delivery date can only be estimated within a certain range, so triangular fuzzy numbers are used here to represent the processing time and delivery date. Each operation O i,j Indicates the jth process of sheet i, it is in the machine M k The processing time on is expressed by triangular fuzzy number (TFN) as in Indicates the minimum processing time, represents the most probable processing time, represents the maximum processing time; the completion time of each operation is expressed as Each number in turn represents the minimum completion time, the most likely completion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com