A processing method for improving burr forming of a polytetrafluoroethylene printed circuit board

A printed circuit board, polytetrafluoroethylene technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of high input cost, low production efficiency, soft texture, etc., and achieve reduced input cost and production efficiency. High, improve the effect of forming burr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

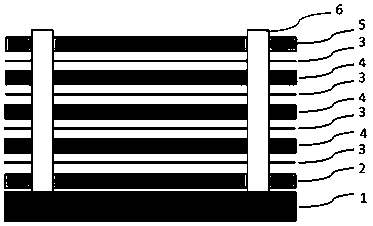

[0030] First, take 18 pieces of polytetrafluoroethylene printed circuit boards, among which, the diameter of the positioning hole of the polytetrafluoroethylene printed circuit board is 3.0mm, the size of the polytetrafluoroethylene printed circuit board is 450*550mm, and the thickness is 2mm ;Take 6 pieces of the first phenolic backing plate and the second phenolic backing plate with a size of 450*550mm and 24 pieces of kraft paper; secondly, import the corresponding gong belt into the gong machine system, and drill several holes on the gong electromechanical board. 2.9mm positioning hole; implant a pin with a diameter of 2.95mm into the positioning hole; again, use a gong machine to drill the phenolic backing plate and kraft paper according to the forming positioning hole pattern of the PTFE printed circuit board, and the hole diameter is 3.0mm; put the first phenolic backing plate 2 on the bakelite board 1 that has been implanted with pins 6 as required; stack a piece of kra...

Embodiment 2

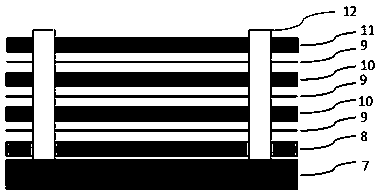

[0032] First, take 12 pieces of polytetrafluoroethylene printed circuit boards, wherein the diameter of the positioning hole of the polytetrafluoroethylene printed circuit board is 3.0mm, the size of the polytetrafluoroethylene printed circuit board is 450*550mm, and the thickness is 1.9 mm; take the first phenolic backing board and the second phenolic backing board with a size of 550*550mm, 6 pieces and 36 kraft paper; secondly, import the corresponding gong belt into the gong machine system, and drill several holes on the gong electromechanical board The positioning hole is 2.95mm; insert a pin with a diameter of 3.0mm into the positioning hole; again, use a gong machine to drill the phenolic backing plate and kraft paper according to the pattern of the positioning hole formed on the PTFE printed circuit board. is 3.05mm; the first phenolic backing plate 8 is set on the bakelite board 7 that has been implanted with pins 12 as required; a piece of kraft paper 9 is stacked on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com