Plantation greenhouse for plants

A technology for greenhouses and plants, applied in the fields of botany equipment and methods, greenhouse cultivation, climate change adaptation, etc., can solve the problems of high cost, high operation difficulty, complex structure, etc., and achieves good environmental protection, low operation difficulty and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

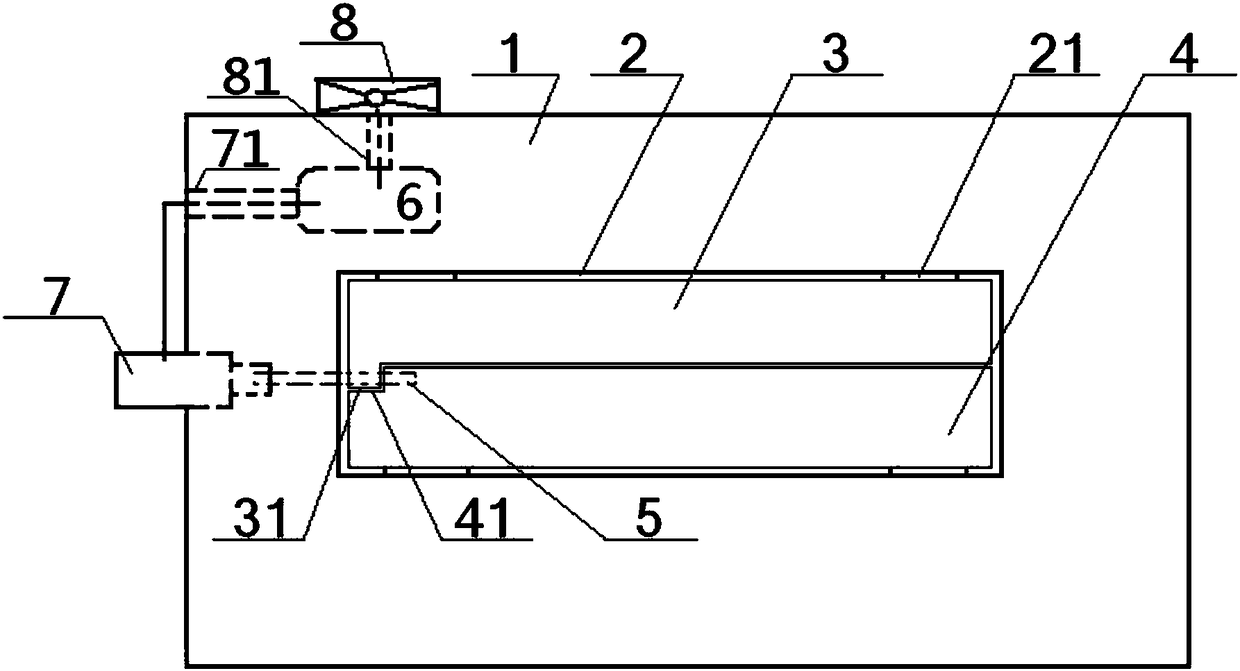

[0016] see figure 1 – figure 2 , a plant planting greenhouse, which includes a skylight in the middle of the roof of the greenhouse 1, and the surroundings of the roof of the greenhouse 1 are connected with the side walls of the greenhouse 1;

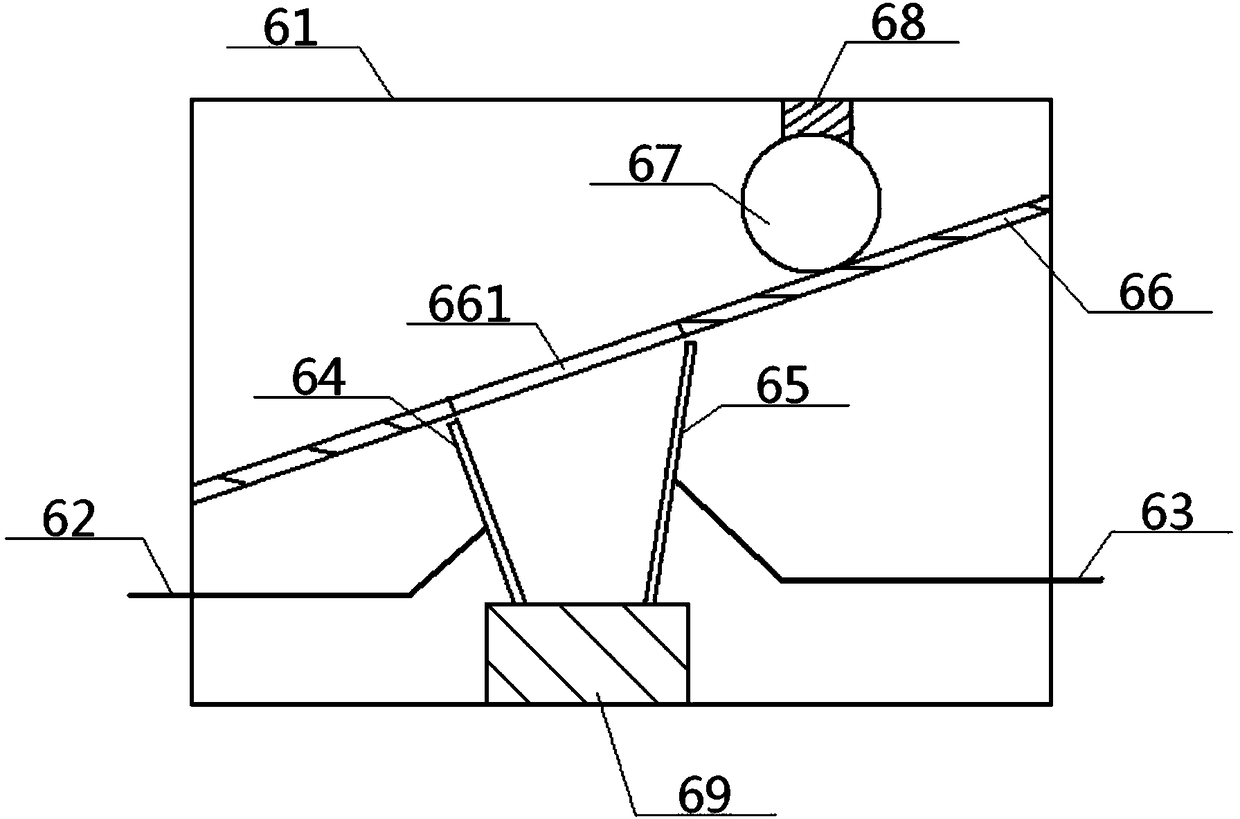

[0017] The planting greenhouse also includes a controller 6, a motor 7 and a power supply 8, the motor 7 and the power supply 8 are arranged outside the planting greenhouse, the controller 6 is arranged inside the planting greenhouse, and the top of the shell of the controller 6 It is connected with the top of the planting greenhouse, and the side part of the shell of the controller 6 is connected with the side part of the planting greenhouse through the motor conduit 71 and the power supply conduit 81 respectively, and the controller 6 and the motor are arranged in the motor conduit 71. 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com