Environmental-friendly building rubbish recovering and treating equipment

A technology for recycling and processing construction waste, which is applied in the direction of grain processing, solid separation, and separation of solids from solids with airflow, etc. It can solve problems such as inability to remove dregs, dust, pollution, and land occupation, and achieve optimal practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

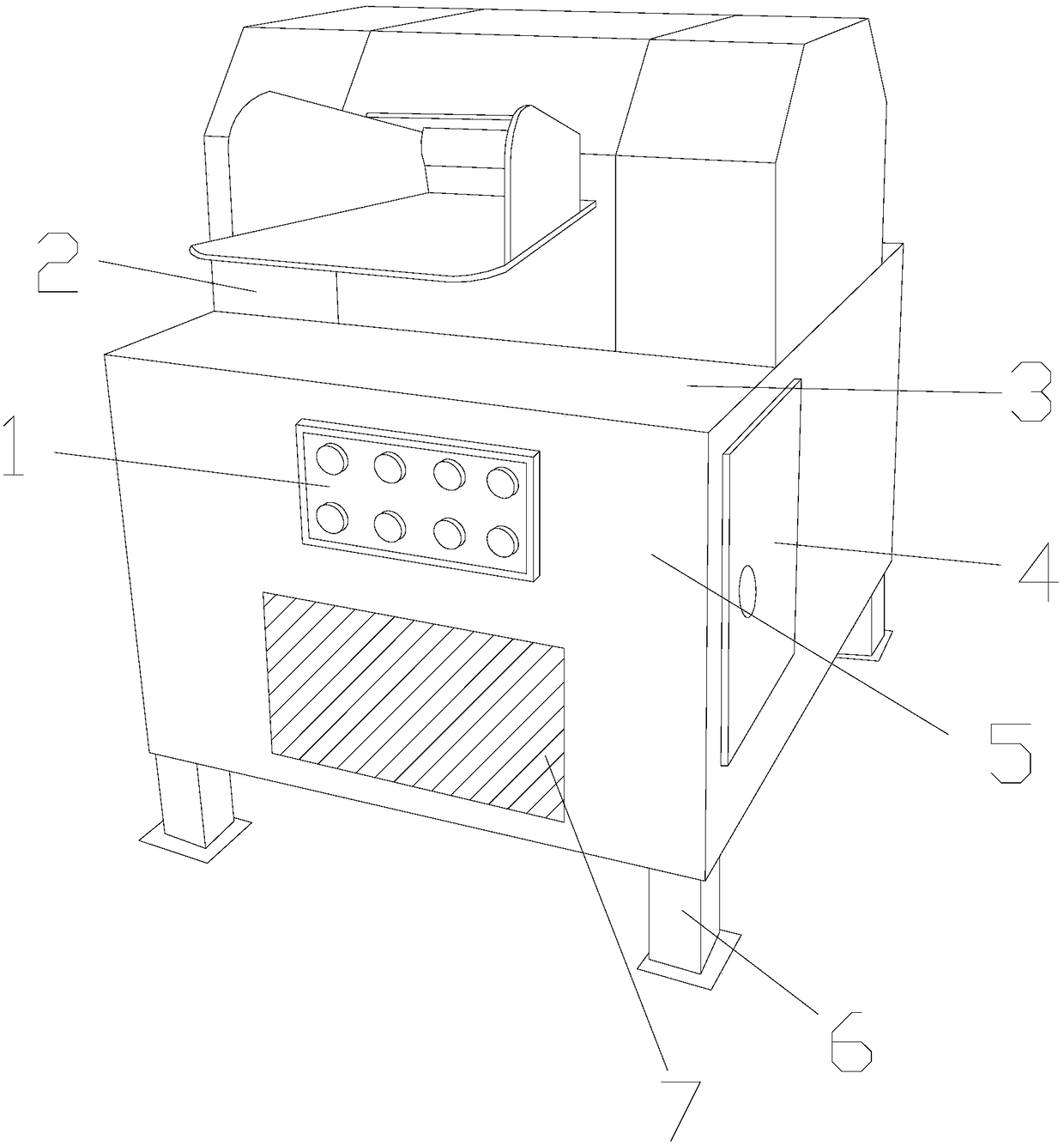

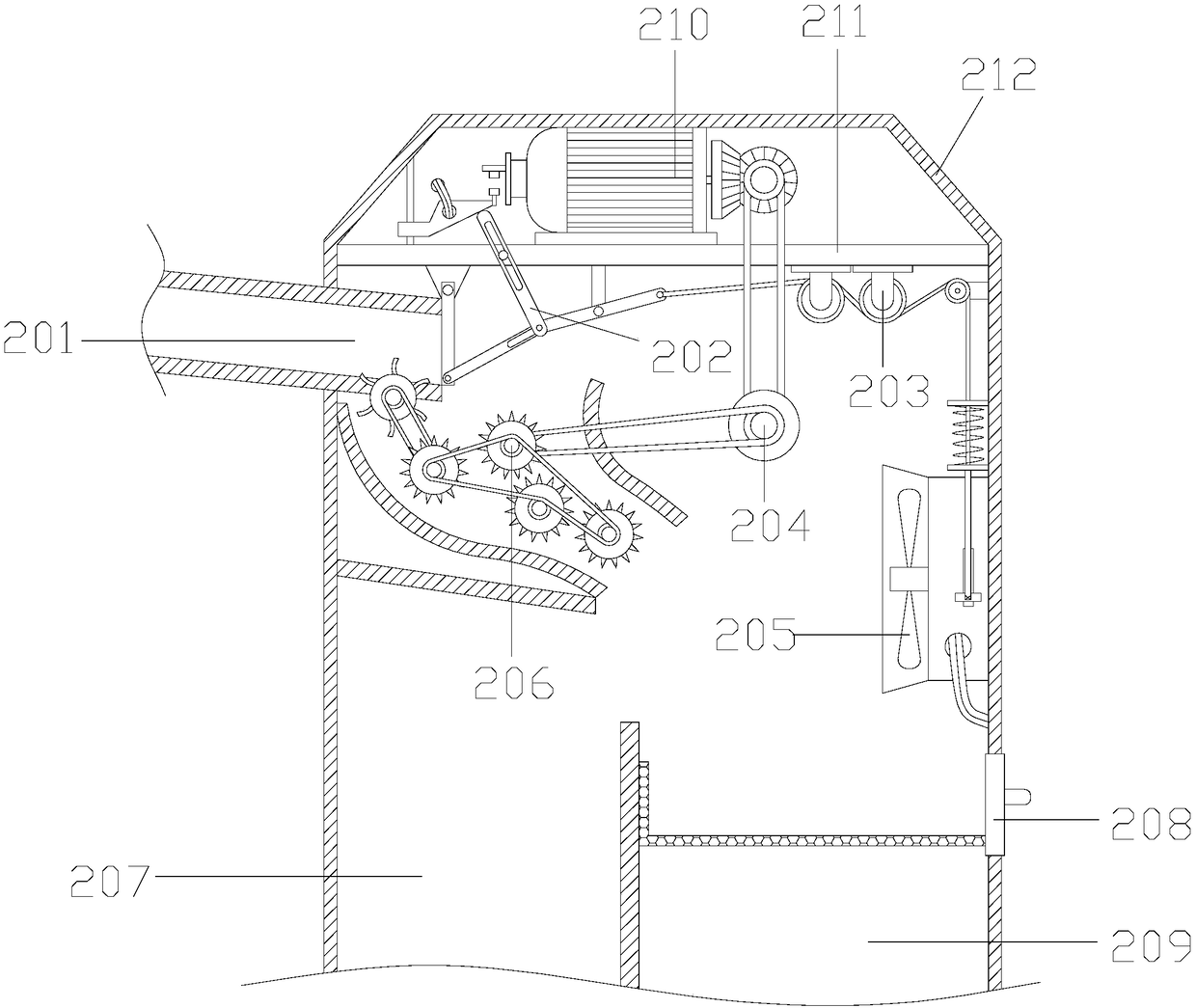

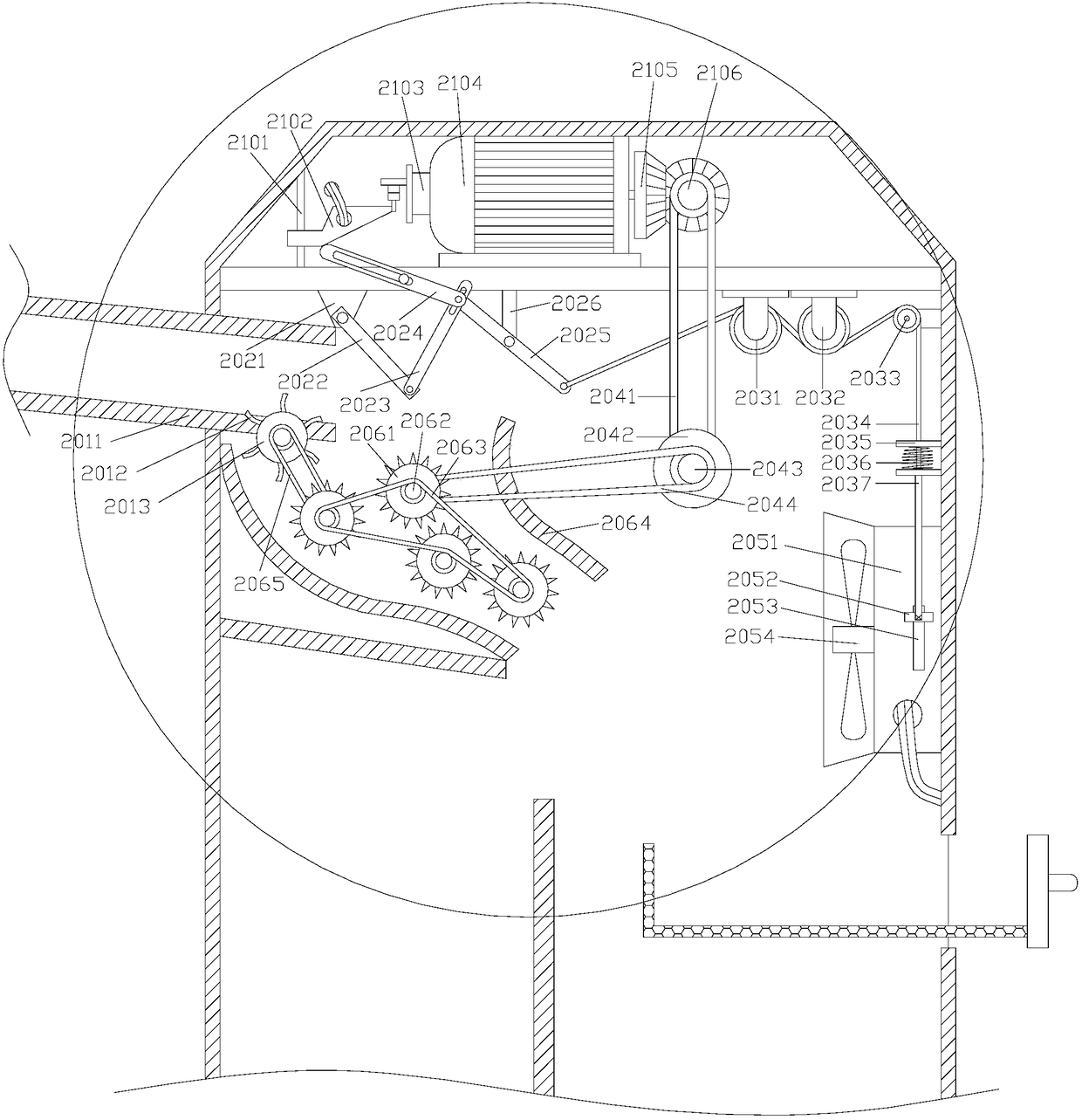

[0021] see Figure 1-Figure 4, the present invention provides environmentally friendly construction waste recycling and processing equipment, the structure of which includes a control panel 1, a processing box 2, a work surface 3, an inspection door 4, a host 5, a fixed foot 6, and a heat sink 7. The fixed foot 6 A total of four are installed on the four corners of the bottom of the host 5 by welding. The lower end of the front surface of the host 5 is provided with a cooling groove 7 and is integrally formed. The upper end of the front surface of the host 5 is provided with a movable installation control panel. 1, the bottom of the processing box 2 is installed on the rear end of the worktable 3 by embedding and is located inside the main machine 5, the upper end of the main machine 5 is provided with a worktable 3 and is integrally formed, and the maintenance The door 4 is installed on the front end of the right end side of the main machine 5 by buckling, and the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com