L-shaped groove type cement drill

A technology of cement and drill bits, which is applied in the direction of stone processing tools, manufacturing tools, stone processing equipment, etc., can solve the problems of high production cost, slow discharge of cement drill bits, and single groove of drill bits, so as to reduce waste and defective products and reduce contact Area, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below for further understanding of the present invention.

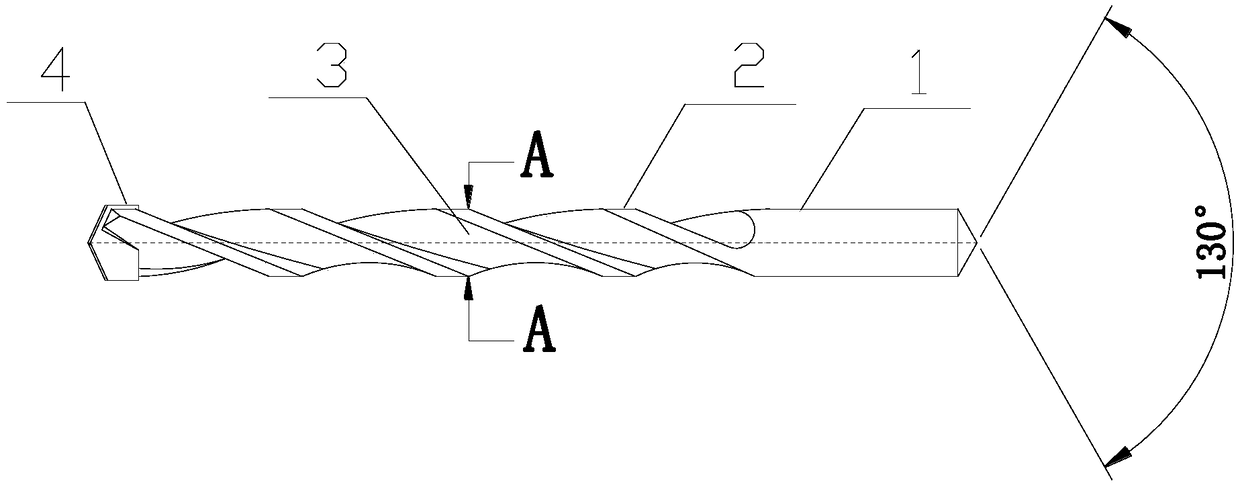

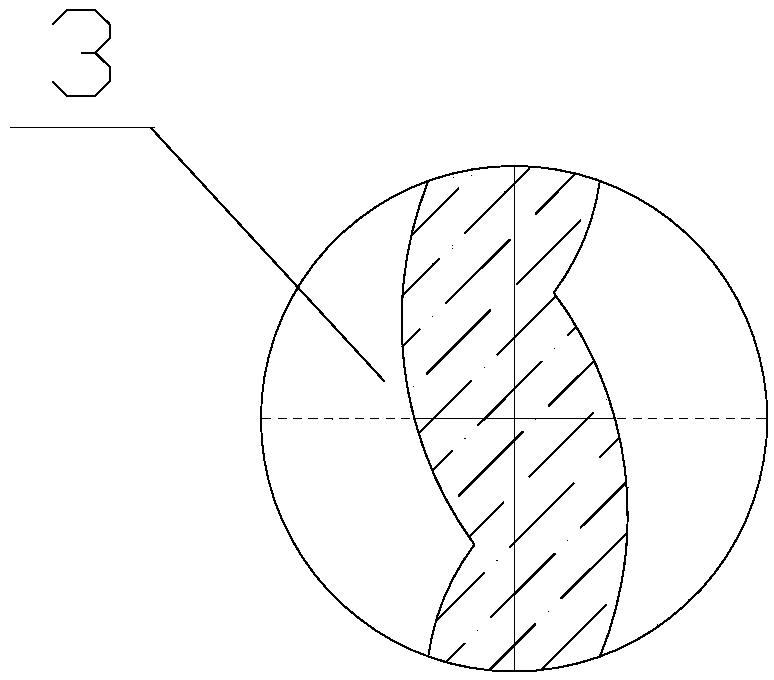

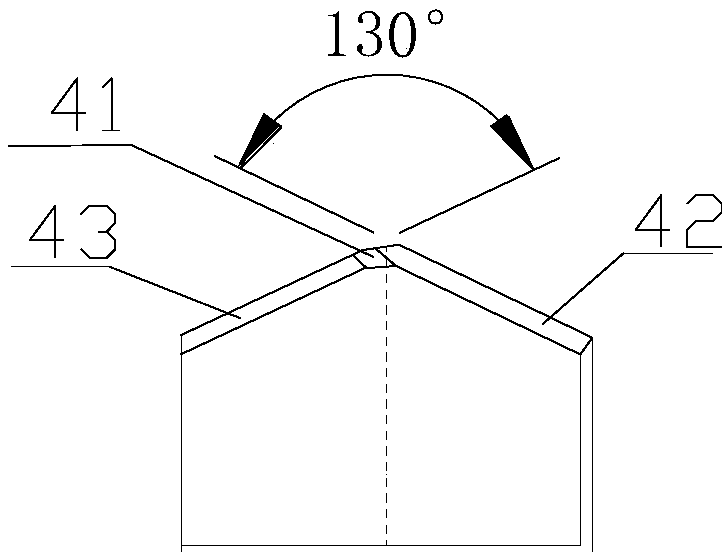

[0019] figure 1 It is a schematic diagram of the L-groove cement drill of the present invention. figure 2 for figure 1 The A-A section view of the L-groove cement drill. image 3 It is a schematic diagram of the drill bit of the L-groove cement drill of the present invention. as the picture shows:

[0020] An L-groove cement drill, comprising a drill rod 1 and a working section 2 arranged at the front end of the drill rod 1, the working section 2 is provided with a chip removal groove 3, and the groove type of the chip removal groove 3 is L-shaped , the front end of the working section 2 is provided with a drill bit 4, the drill bit 4 extends forward to form a head of a conical structure, the head is composed of a plurality of inclined surfaces connected to each other, and the included angle of the head is 130 degrees .

[0021] Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com