Manufacturing method of automobile mark

A manufacturing method and a technology of automobile signs, which are applied in the field of auto parts, can solve the problems of heavy environmental pollution, complicated manufacturing process, and affecting the toughness of buckle feet, etc., and achieve the effect of reducing the coating process, avoiding multiple electroplating, and increasing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

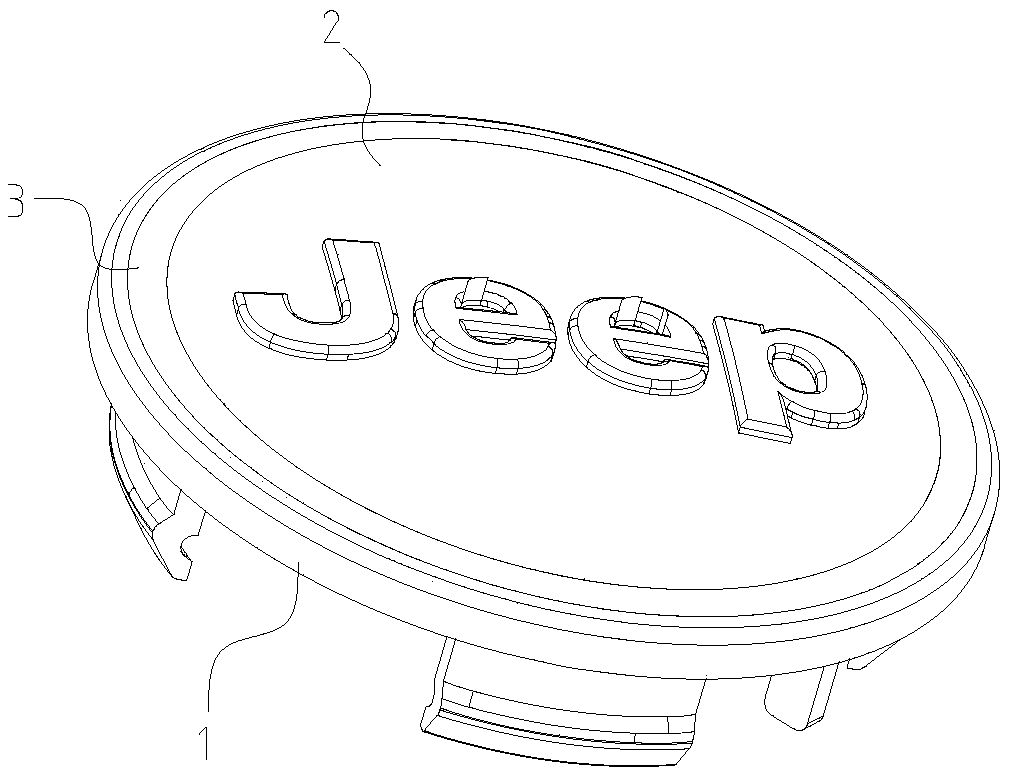

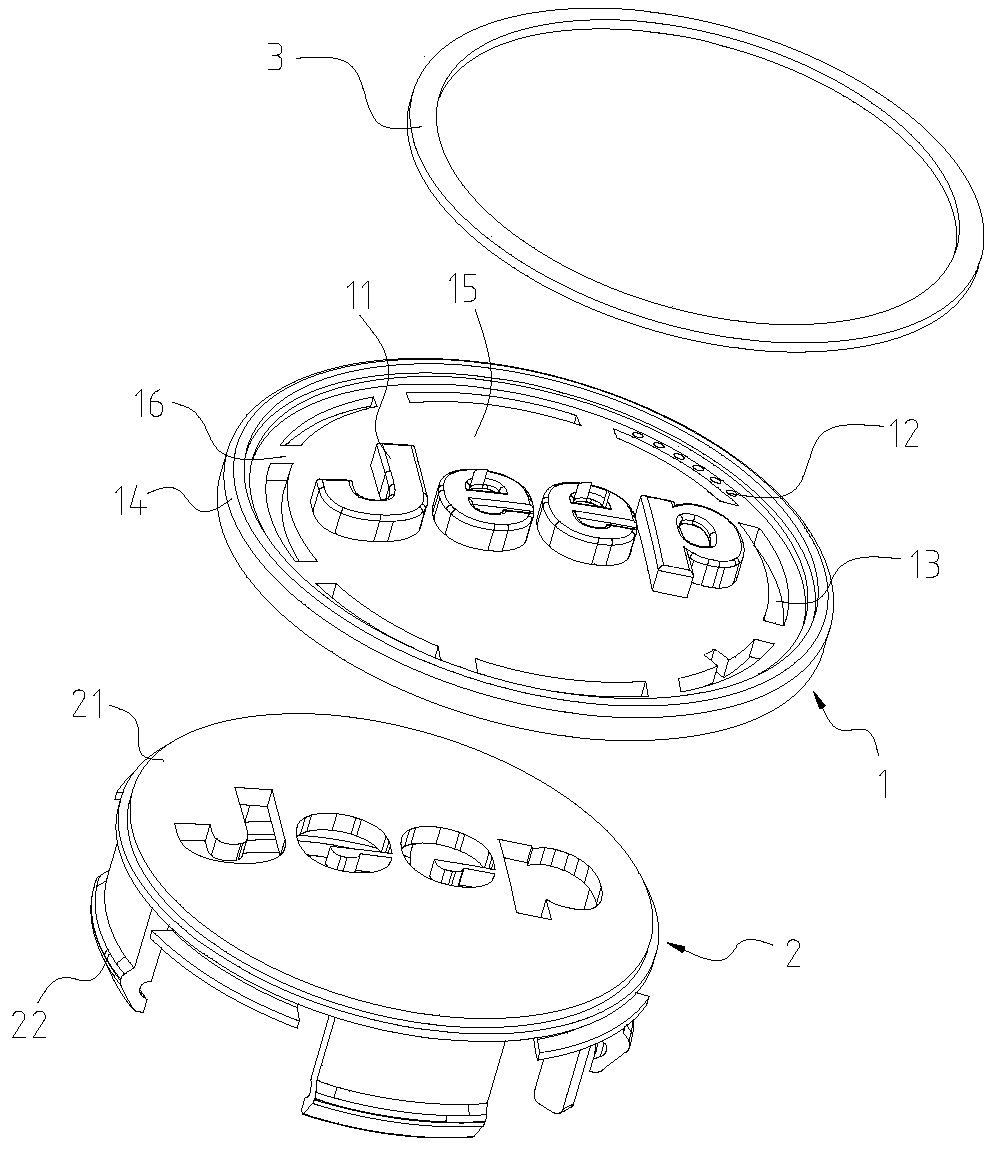

[0023] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0024] like figure 1 , 2 As shown, a car logo includes a first part 1 and a second part 2, the two parts are injection molded separately, the first part 1 is an electroplated part, the first part 1 is provided with a logo 11, and the second part 2 is provided with There are buckle feet 22, and the first part 1 and the second part 2 are combined by injection molding.

[0025] like figure 1 , 2 Shown, a kind of manufacture method of automobile sign, comprises the following steps:

[0026] (1) The first part 1 is injection molded by using the first plastic, which is an engineering plastic resistant to high temperature and high pressure, so as to ensure that the first part 1 will not be deformed when it is put into the mold for injection molding. The component 1 includes a frame 14, a carrier board 15 located in the frame 14 and a logo 11 located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com